0102030405

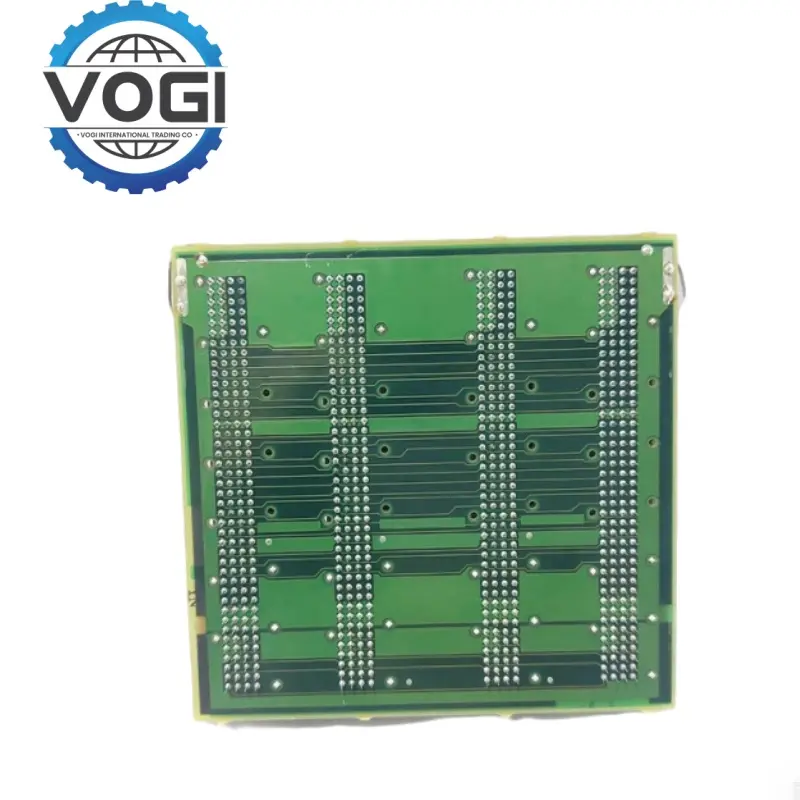

ABB BB150 3BSE003646R1 Board

Key SpecificationsVOGI

Bus standard: PROFIBUS DP V1, compatible with PROFIBUS PA.

Physical interface: DB9 Sub-D connector.

Electrical isolation: 500V AC channel-to-channel isolation, 1500V DC system isolation.

Input data: 244 bytes/station.

Output data: 244 bytes/station.

Protection level: IP20

Power supply requirements: 24V DC ±10% (redundant power supply support), power consumption ≤5W.

Operating temperature: -20°C to + 60°C (fanless design, natural convection heat dissipation).

Anti-interference ability: Complies with IEC 61000-6-2 industrial electromagnetic compatibility standards, and can resist high-frequency harmonics and radio frequency interference.

Explosion-proof certification: Optional ATEX Zone 2 (gas environment) or Zone 22 (dust environment) certified models are available for non-continuous hazardous areas.

Key FeaturesVOGI

1. High reliability industrial design

Hardware redundancy: ABB BB150 supports dual power input and communication link redundancy to ensure continuous operation of the system in the event of a single point failure.

Hot-swap function: The module can be replaced under power, and maintenance does not require shutdown, reducing production interruptions.

Fault isolation: Each channel of ABB BB150 is independently electrically isolated to avoid short circuit propagation, and supports optional fuses (2.0A).

2. Intelligent diagnosis and remote monitoring

Real-time status monitoring: 4-color LED indicators display power, communication, overload, and short circuit status to quickly locate faults.

Self-diagnosis function: ABB BB150 has built-in overcurrent/overvoltage protection, which automatically cuts off the output and sends an alarm signal through the bus when abnormal.

Remote configuration: Remotely adjust communication parameters and diagnostic thresholds through ABB Ability™ or third-party configuration software.

3. Hazardous area adaptability

Explosion-proof design: ATEX certified models support Ex nA II T3 Gc or Ex tb IIIC T135°C Db, suitable for non-continuous hazardous environments such as petrochemical, oil and gas.

Intrinsically safe interface: ABB BB150 can be connected to intrinsically safe actuators to ensure safe signal transmission in hazardous areas.

4. Flexible scalability

Modular architecture: ABB BB150 can be mixed with other modules of the S900 series to meet complex I/O requirements.

Multi-protocol support: It can be expanded to PROFINET, Modbus TCP and other protocols through gateway modules, and is compatible with heterogeneous systems.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$43 |

|

Southeast Asia |

$31 |

|

South Asia |

$56 |

|

South Africa |

$46 |

|

Europe and USA |

$28 |

|

Russia |

$51 |

APPLICATIONVOGI

1. Process Industry

Petrochemical and Chemical Industry: In the temperature control of reactors and the pressure regulation of distillation towers, the PROFIBUS DP communication capability of BB150 enables high-speed data interaction with ABB AC800M controllers. ATEX certified models can be deployed in explosion-proof areas.

Papermaking and Metallurgy: Used for coating machine tension control and continuous casting machine crystallizer cooling water valve control, supporting redundant configuration to ensure continuous production.

2. Energy and Electricity

Wind Power and Photovoltaic: In the control of grid-connected switches of converters and switching of reactive compensation devices, the fast response characteristics (<10ms) improve the stability of the power grid.

Substation Automation: Cooperate with ABB RELION protection relays to realize remote switch control and fault isolation of smart grids.

3. Infrastructure

Water Treatment System: Control aeration fan inverters and regulating valve openings to optimize sewage treatment efficiency, and support MODBUS protocol and SCADA system integration.

Smart building: Linked with ABB i-bus system to adjust central air-conditioning chillers and lighting systems to achieve energy management.