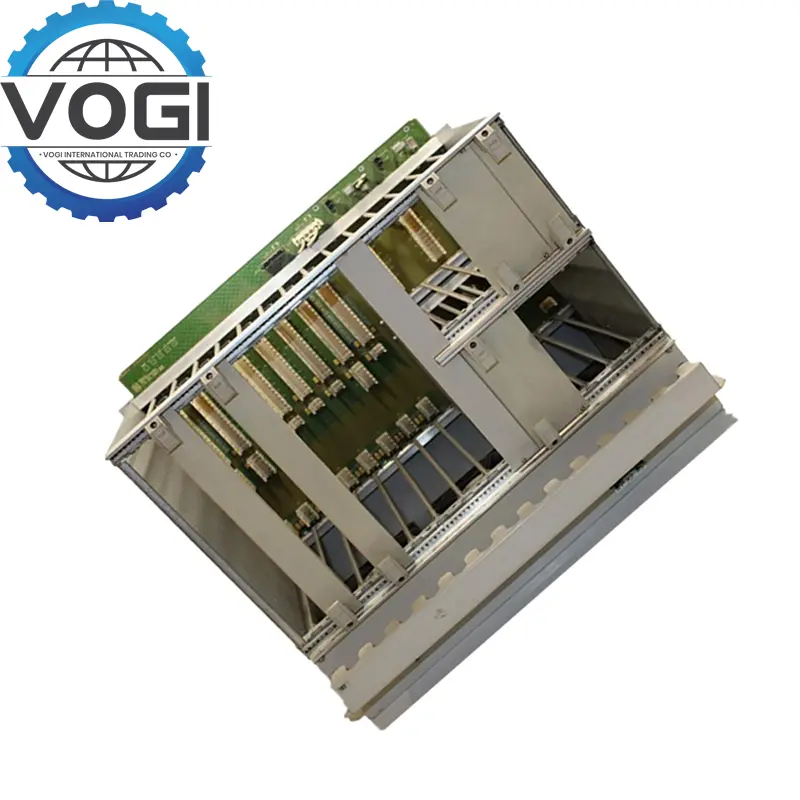

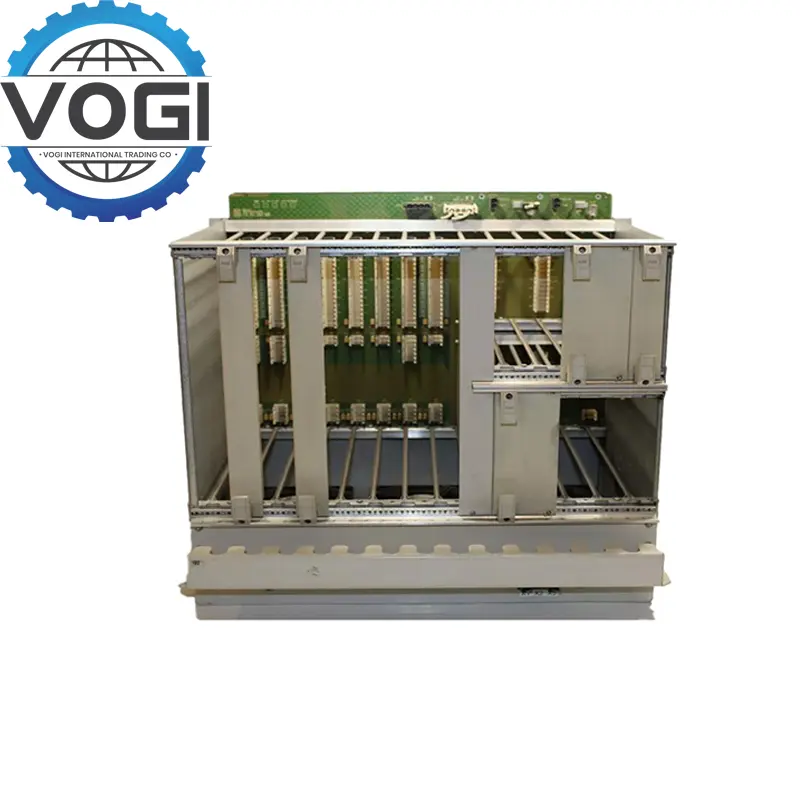

ABB HAC349A System Rack

Technical ParametersVOGI

Part Number: HAC349A (HIEE300857R1)

Module Type: System Rack / Backplane for S800 I/O modules

Supply Voltage: 24 V DC ± 10 %

Power Consumption: ≤ 10 W (backplane only)

Operating Temperature: –40 °C to +85 °C

Humidity: 5–95 % RH, non-condensing

Isolation: Backplane galvanic isolation per slot to withstand industrial transients

Mounting: DIN-rail or cabinet-mounted; accepts HIEE bus connectors

Slots: Backplane with multiple module slots (model-dependent; typically up to 12)

Connectors: Robust 64-pin backplane connectors for power, ground, and data bus

Key FeaturesVOGI

Passive Backplane Design: ABB HAC349A Provides power and communications bus to up to a dozen S800 I/O or controller modules without active electronics in the rack itself.

Hot-Swap Capability: ABB HAC349A Enables insertion and removal of individual I/O modules under power in redundant configurations, minimizing downtime.

Wide-Range Ruggedness: Rated for extreme temperatures (–40 °C to +85 °C) and industrial humidity, ideal for harsh field-mounted enclosures.

Galvanic Slot Isolation: ABB HAC349A Each slot is isolated to protect against ground-loop and transient faults, preserving data integrity across all modules.

Compact Footprint: Slim single-rack profile conserves cabinet space while accommodating numerous modules side by side.

Universal Mounting: Compatible with standard ABB rack frames and DIN-rail arrangements for flexible installation.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$58 |

|

Southeast Asia |

$48 |

|

South Asia |

$78 |

|

South Africa |

$62 |

|

Europe and USA |

$39 |

|

Russia |

$70 |

APPLICATIONVOGI

Water & Wastewater Treatment Skids

Deployed as the backbone rack for S800 remote I/O modules on booster-pump and filtration-unit skids—monitoring flows, levels, and valve positions in municipal treatment plants.

Oil & Gas Process Control Panels

Houses analog and digital I/O modules for feed-forward and feedback loops in separation, dehydration, and compressor-station skids on offshore platforms and pipe-rack installations.

Power Generation DCS Nodes

Installed in turbine-control and feedwater-regulation panels within thermal, hydro, and combined-cycle power plants to host sensor-input and actuator-output modules under the main control system.