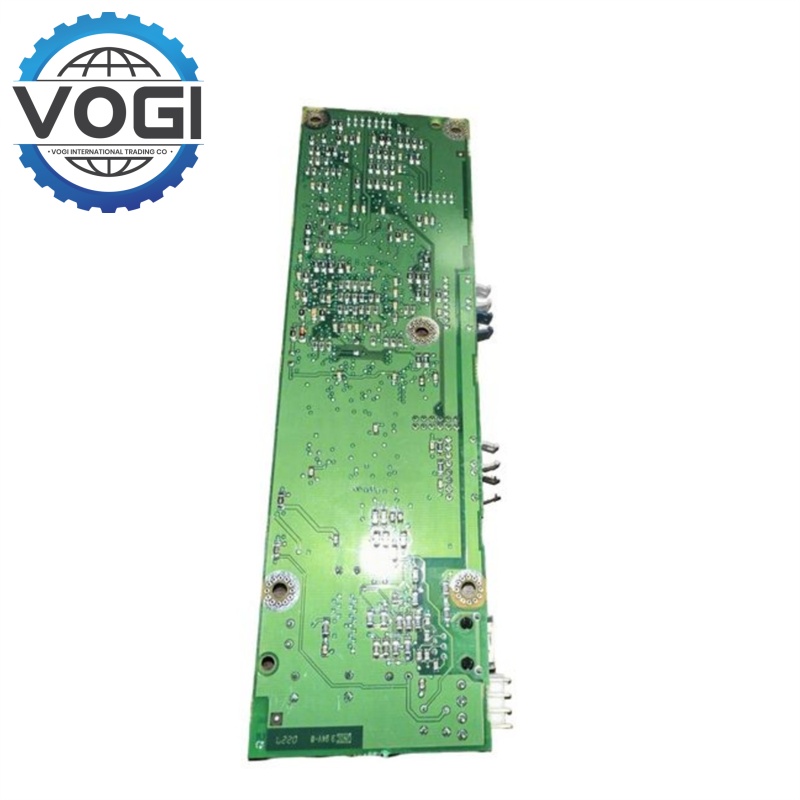

ABB NAMC-51C 3BSC980006R326 Control Board

Key SpecificationsVogi

ACthree-phase input voltage: 380V ±10%

Frequency range: 50/60 Hz

Control mode: V/F control orvector control

Efficiency: ≥95%

Overload capacity: 150%of rated current

Inputterminals: 3-phase mains voltage, DC link interface

Output Terminals: 3-phase motor interface, brake resistor terminal

Control signal: analog input(0-10V/4-20mA), Digital input (Closed/open, forward and reverse)

PID,proprietary close-loop control function

Multi-function encoder interface: upto AB phase orthogonal encoder feedback

Communication interface: RS485 (Modbus RTU) Profibus (optional)

Temp: -10°C~ +50°C (no condensation)

Storagetemperature: -20°C ~ +60°C

Freight Estimation(Part Of The Area)Vogi

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

FeaturesVogi

1. Universal Control Processing Algorithm: Proven ability of complex control processing algorithms can accurately adjust the control parameters of various old and new industrial processes or industrialequipment. ABB NAMC-51C can thus from his control know how to use the actuator and at what speed, torque, and even to position work, so that it can work well insuch as conveying systems, where machine tools and robotic arms system segmentation.

2. Diagnostic and monitoringfunctions: It has powerful diagnostic functions to detect faults or abnormal conditions in real time. The ABB NAMC-51C is capable of monitoring the voltage, current, temperature and the statusof the connected components. So if there is a fault in the inside of the monitor, itwill automatically use the visual indicator on the monitor or send the message to the central control system to request assistance, so as to make the occupy dwell in the opening of the equipment problem quickly.

3. Smart Interface: It can be configuredvia dedicated software or from the device's settings to display a friendly configuration interface. According to the requirements of a specific application, users can flexibly configure input/output, control mode, alarmthreshold and other parameters, which can be applied in various industry scenarios.

4. Redundancy/backup function: In some critical applications, ABB NAMC-51C may serve as abackup or redundant system, ensuring continued operation of the controlled process even if one system component fails. Reliability: The system may be designedto have redundant communication paths or backup power supplies.

APPLICATIONSVogi

1. Use Cases Examples: Used in Industrial Automation – It is commonly employed in factories to power motors, conveyors, heating pumps andother devices used in production. It streamlinesproduction processes, enhances product quality, and boosts productivity.

2. Power Generation: Inpower plants, ABB NAMC-51C can be used to manage auxiliary equipment (e.g., turbine speed governors, generator cooling systems, fuel supply systems, etc.). It allows power generation facilities to run smoothly and efficientlythrough accurate control and monitoring.

3. Chemical Industry: Control of pipelines and reactors (flow, temperature, and pressure)in the chemical, pharmaceutical, and food processing industries NAMC-51C. (The production process is for example certifiedsafe and secure.)

4. Material handling and logistics: It used in warehouses, ports and distribution centers to manage conveyor belts, cranes and automated guided vehicles for the smooth movement of goods andtheir handling.