0102030405

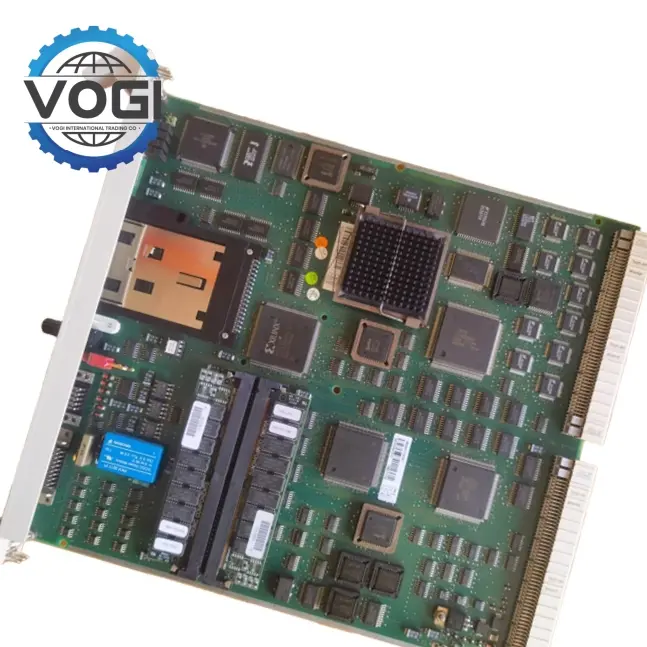

ABB PM511V16 3BSE011181R1 Processor Module

Key SpecificationsVOGI

CPU Type: 32-bit RISC processor.

Clock Speed: 100 MHz.

Program Memory: 16 MB (flash).

Data Memory: 8 MB (RAM).

Execution Speed: ~0.1 ms/kB for ladder logic.

Standard Interfaces:

1 x Ethernet (10/100 Mbps, TCP/IP, Modbus TCP).

1 x RS-485 (Modbus RTU, CANopen optional).

Expansion Bus: Supports I/O expansion via Serial Highway 2 (SH2).

Protocol Support: Modbus, CANopen, Profibus DP.

Voltage: 24 V DC (±20%).

Power Consumption: ~5 W.

Key FeaturesVOGI

Convenient programming method: ABB PM511V16 adopts the programming language of IEC 61131-3 standard and has a user-friendly programming interface, which is convenient for engineers to develop and debug programs, shorten the project development cycle and reduce development costs.

Triple isolation protection: Triple isolation between channels, channel-ground, and channel-system power supply (2500Vrms), common mode rejection ratio (CMRR)>160dB, and can withstand strong electromagnetic interference such as arc furnaces and inverters.

24-bit high-resolution ADC: Basic accuracy reaches ±0.01% FS (full scale), temperature drift <0.5ppm/°C, and can accurately capture microvolt signal changes (such as small pressure fluctuations in chemical reactors).

Live maintenance: ABB PM511V16 supports uninterrupted power replacement of modules, combined with redundant power supply design to ensure system availability>99.999% (annual downtime <5 minutes).

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$43 |

|

Southeast Asia |

$15 |

|

South Asia |

$56 |

|

South Africa |

$46 |

|

Europe and USA |

$27 |

|

Russia |

$51 |

APPLICATIONVOGI

Process industry: In the reactor control system of a chemical company, ABB PM511V16 undertakes the important task of monitoring and regulating the reaction process. It collects parameters such as temperature, pressure, flow rate, etc. in the reactor in real time, and adjusts the opening of the feed valve, the speed of the agitator, and the operating status of the heating or cooling equipment according to the preset process requirements to ensure that the chemical reaction is carried out under safe and stable conditions and improve the quality and yield of the product.

Transportation field: In the intelligent traffic signal control system of a certain city,ABB PM511V16 automatically adjusts the duration of traffic lights based on real-time monitoring data of vehicle and pedestrian flow. Through the connection with vehicle detectors and pedestrian sensors, PM511V16 can accurately calculate traffic flow in different directions, reasonably allocate green light time, reduce vehicle waiting time and congestion, and improve the traffic efficiency of urban roads.

Food and beverage industry: On the filling production line of a food processing plant, ABB PM511V16 controls the running speed, filling volume and action of the capping equipment of the filling machine. It ensures that each packaging container can be accurately filled with a certain amount of food and completes subsequent processes such as capping, thus ensuring the packaging quality and production efficiency of the product.