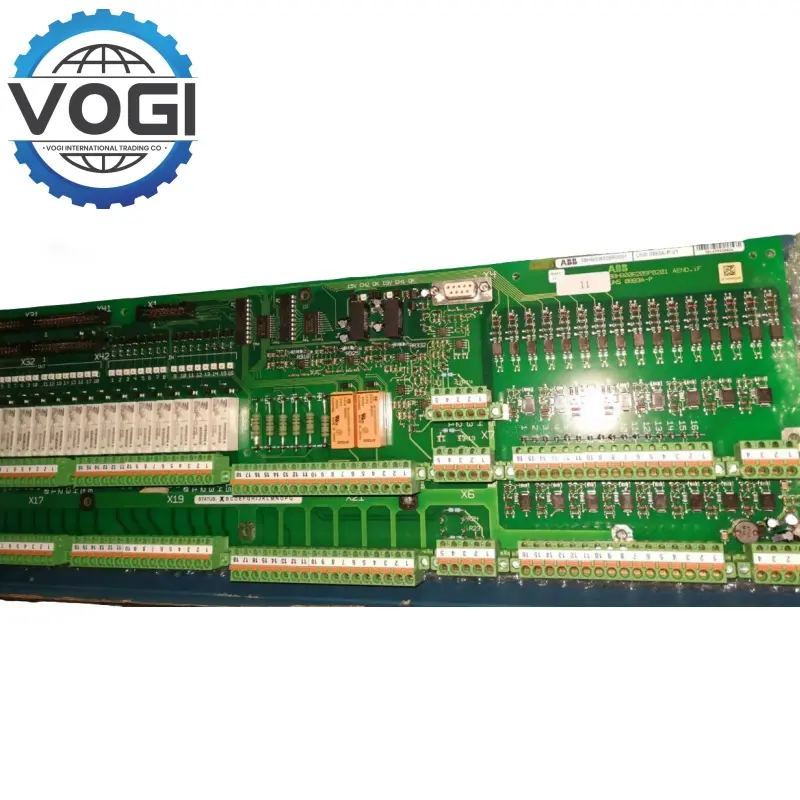

ABB UNS0883A-P,V1 3BHB006208R0001 CONTROL BOARD

Key SpecificationsVOGI

Power input: usually 24V DC

Industrial standard level input and output (0-10V, 4-20mA, dry contact, etc.)

DI_PURPOSE: Digital input (DI): 8-16 channels, support high-speed response

DO: 8-16 channels, relay or transistor output support

Analog input/output (AI/AO): 4-8 channel(s) in some models, depending on version

Communication protocol: support PROFIBUS, MODBUS, etc. industrial bus protocol

Key FeaturesVOGI

Core advantages

Fast response: Microsecond processing (DI/DO) of the ABB UNS0883A-P, V1 can control rapidly changing scenarios such as excitation systems in real time.

High reliability:

Anti electromagnetic interference through photoelectric isolation + metal shielding, can be suitable for harsh industrial environment (-25°C~+70°C).

The combination of dual redundant power input and fault self-diagnosis (LED indicator + alarm) can greatly reduce the risk of downtime.

Flexible adaptation:

ABB UNS0883A-P, V1 is compatible with industrial communication protocols like PROFIBUS, MODBUS, and is easy to connect with mainstream PLC/DCS systems.

A modular design (DIN rail installation) facilitates rapid expansion with modules of the same series (eg, UNS0880A/P).

Functional parameters

Basic I/O: 16x DIO (Optional AIO) To Interact Signals With Multiple Devices

Communication interface: The ABB UNS0883A-P, V1 has built-in PROFIBUS DP, MODBUS or Ethernet

Parameter size: ABB UNS0883A-P, V1 compact disk (About 30 × 20 × 20cm), light weight, easy to install.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

APPLICATIONVOGI

Generator/motor: Real-time acquisition of voltage, current, temperature and other signals, dynamic adjustment of excitation current (such as stabilizing generator voltage and optimizing motor power factor)

Protection linkage: get fault signal (such as abnormal speed, winding overheat), trigger demagnetization, stop and perform other protection actions quickly.

Industrial automation control

Remote I/O module: communicate with PLC/DCS system and field equipment (sensors, valve, pump), upload status data, and control instruction (for instance, process automation in production line).

Commodity conditions monitoring: real-time monitoring of vibration, pressure, liquid level and other signals, automatic alarm or chain shutdown when exceeding threshold (such as fan bearing overheating protection).

New energy auxiliary control

Wind power/photovotaic : adaptation to double fed generator or inverter, response to network change (wind power max power tracking, photovoltaic anti-islanding protection)