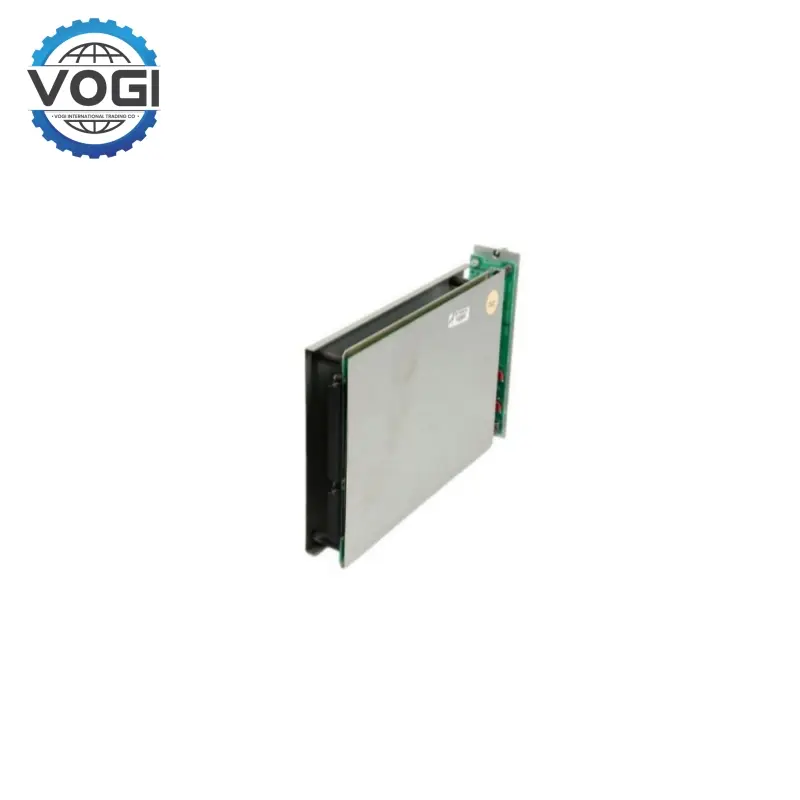

Bently Nevada 3300/01-01-00 System Monitor

Key SpecificationsVogi

Power supply: It requires regulated DC voltage from a separate rack power supply.

Power consumption: typical 2 watts; with serial interface option, 3.6 watts.

Typical operating voltage: 220 volts.

Output frequency: 50 kilohertz.

Frequency response: 0-10kHz

Working current: 12mA

Operating temperature range: -35°C to +85°C

key FeaturesVogi

Multi-channel monitoring: Supports multi-channel vibration measurement, which can monitor various points on the machine at the same time, and can also detect vibration anomalies in different parts and locations.

Advanced signal processing: The Bently Nevada 3300/01 is capable of some advanced signal processing, which can filter signals that easily interfere with the original vibration signal

Integrated temperature compensation: Although temperature changes may change the vibration characteristics of the machinery, this can compensate for the accuracy and reliability of this data over any temperature range

Alarm and threshold setting: The Bently Nevada 3300/01 allows users to set custom alarm thresholds for vibration levels.

Extensive diagnostic capabilities: In addition to regular monitoring of vibration, advanced diagnostic functions are also provided. These functions include spectrum analysis, track analysis and trend monitoring

Freight Estimation(Part Of The Area)Vogi

|

Destination |

Freight |

|

Middle East |

$43 |

|

Southeast Asia |

$16 |

|

South Asia |

$56 |

|

South Africa |

$47 |

|

Europe and USA |

$28 |

|

Russia |

$51 |

ApplicationVogi

Industrial field: Identification of shaft vibration and displacement ensures stable operation of the unit. Once a mechanical failure occurs, it can avoid the shutdown of the power plant turbine.

Petrochemical industry: Real-time online equipment operation status monitoring, early detection of abnormalities, provide a basis for equipment maintenance, and improve production safety and continuity.

Aircraft engine: Provide high sensitivity to optimize engine performance, thereby ensuring flight safety and providing guarantee for the stable growth of the aviation industry.

StrengthsVogi

Precise measurement: It can accurately measure key indicators such as shaft vibration and displacement of large rotating machinery, truly prevent mechanical failure and shutdown, and ensure production continuity.

Real-time monitoring: It can capture the operating status of compressor equipment in the petrochemical industry, detect abnormal conditions, and prevent dangerous accidents.

High sensitivity: Especially in aircraft engine testing, the device can check engine performance with high sensitivity, ensure flight safety, and lay a solid foundation for the aviation field.