In the rapidly evolving landscape of industrial automation, the year 2025 is set to witness groundbreaking innovations in PLC control systems that promise to redefine operational efficiency and flexibility across various sectors. According to Dr. Emily Stanton, a leading expert in industrial automation and control systems, “The next generation of PLC control systems will not only enhance productivity but also integrate smart technologies that allow for unprecedented levels of real-time data analysis.” This sentiment encapsulates the thrust of technological advancements we anticipate in the coming years, which will pivot on the heart of modern manufacturing—PLC control systems.

As industries continue to embrace automation, understanding the trends and innovations within PLC control systems becomes crucial for professionals aiming to stay ahead of the curve. From the integration of artificial intelligence to the deployment of cloud-based solutions, these innovations are designed to streamline operations, reduce downtime, and improve overall system resilience. The following analysis will delve into the top ten PLC control system innovations slated for 2025, exploring how each breakthrough can potentially transform industry practices and contribute to a more efficient and responsive manufacturing environment. By harnessing the power of these advances, businesses can foster a competitive edge in an increasingly complex market.

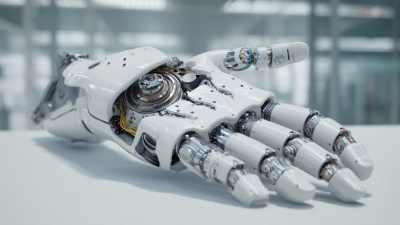

The rise of AI-driven PLC (Programmable Logic Controller) systems is revolutionizing the landscape of industrial automation. These innovative systems leverage advanced algorithms to enhance decision-making processes, allowing for real-time adjustments in manufacturing and production environments. By integrating machine learning capabilities, AI-driven PLCs can analyze vast amounts of data collected from sensors and equipment, predicting potential failures and optimizing operations proactively. This increased responsiveness not only minimizes downtime but also boosts overall efficiency in production lines.

Moreover, AI in PLC systems enhances the adaptability of manufacturing processes. As industries face rapidly changing market demands, these intelligent systems can quickly reconfigure themselves to accommodate new workflows without extensive manual intervention. This agility ensures that companies remain competitive, as they can easily pivot their operations to meet evolving customer needs. Additionally, improved user interfaces and visualization tools driven by AI further empower operators, providing them with insights that foster better decision-making and a more streamlined approach to automation.

The integration of the Internet of Things (IoT) with Programmable Logic Controllers (PLC) is transforming real-time data monitoring and control across various industries. This convergence allows for unprecedented levels of automation, efficiency, and data analysis capabilities, empowering businesses to respond quickly to dynamic operational needs. As industries increasingly embrace digital transformation, the demand for advanced PLC systems that incorporate IoT technologies continues to rise, paving the way for smarter manufacturing processes and enhanced operational insights.

The market for industrial automation, including PLC systems, is set to experience significant growth in the coming years, with projections estimating a rise to $2.1 trillion by 2025. This growth is driven by the need for improved efficiency, safety, and productivity across sectors such as oil and gas, chemicals, and automotive manufacturing. The implementation of IoT in PLC systems facilitates real-time monitoring and predictive maintenance, thereby minimizing downtime and optimizing resource utilization, which are crucial for maintaining competitive advantages in today's fast-paced industrial landscape.

| Innovation | Description | Key Benefits | Industry Impact |

|---|---|---|---|

| Smart Sensors Integration | Use of advanced sensors that provide real-time data to PLC systems. | Enhanced accuracy, reduced downtime, improved monitoring. | Greater efficiency in manufacturing processes. |

| Cloud-Based PLC | Integration of cloud computing for data storage and analysis. | Remote access, increased data storage, scalability. | Adoption of Industry 4.0 principles. |

| AI-Driven Analytics | Leveraging AI to analyze data from PLCs for predictive maintenance. | Reduced maintenance costs, proactive fault detection. | Increased reliability of machinery. |

| Edge Computing | Processing data at the edge for faster decision-making. | Reduced latency, improved response times. | Streamlined operations in real-time environments. |

| Augmented Reality Interfaces | Utilizing AR to enhance operator training and maintenance procedures. | Improved training efficiency, reduced human error. | Empowerment of workforce and operational excellence. |

| Integrated IoT Solutions | Seamless connection between IoT devices and PLC systems. | Informed decision-making, holistic monitoring. | Increased operational transparency across industries. |

| Cybersecurity Enhancements | Advanced security protocols for protecting PLC systems. | Enhanced data protection, reduced risk of breaches. | Strengthened infrastructure security. |

| Modular PLC Designs | Designing PLC systems that can be easily expanded or upgraded. | Flexibility, easier maintenance, cost-effective upgrades. | Adaptability to evolving industrial needs. |

| Real-Time Monitoring Dashboards | Interactive dashboards for real-time data visualization. | Enhanced decision-making, quicker responses. | Greater operational awareness and control. |

| Low-Code Development Platforms | Platforms that allow easier programming of PLCs. | Reduced development time, accessibility for non-programmers. | Broader talent pool for PLC programming. |

The next-generation Human-Machine Interface (HMI) designs are transforming the way operators interact with PLC (Programmable Logic Controller) systems in industrial environments. These innovative HMI solutions focus on enhancing user experience through intuitive designs, touch-sensitive screens, and advanced graphical representations of machinery and processes. By prioritizing user-friendly interfaces, modern HMIs enable operators to monitor and control complex systems more efficiently, reducing the learning curve and minimizing the risk of errors during operations.

Moreover, the integration of augmented reality (AR) and virtual reality (VR) into HMI design is pushing the boundaries of user interaction. These technologies provide immersive visualizations that allow operators to interact with digital representations of their systems in real-time. This not only aids in troubleshooting and maintenance but also offers training opportunities that can significantly shorten onboarding processes. The combination of these advanced interfaces with robust PLC control systems is set to revolutionize industry practices, improving productivity and enhancing safety in manufacturing and automation.

The advancement of PLC (Programmable Logic Controller) systems is ushering in a new era of operational efficiency and sustainability across various industries. With innovations aimed at energy efficiency, manufacturers are increasingly adopting AI-powered operational intelligence that optimizes process control and reduces energy consumption. These systems not only enhance performance but also contribute towards a greener operational footprint, aligning with global sustainability goals.

In addition, innovations in sustainable water treatment are revolutionizing how industries manage resources. By integrating PLC systems with advanced water purification technologies, companies can minimize waste and ensure a more responsible use of vital resources. Decentralized infrastructure is another key area of innovation, allowing for more resilient and adaptive operational frameworks that can respond quickly to local challenges, such as flood prevention.

Tips: When considering PLC system upgrades, focus on energy-efficient models that incorporate AI technologies. This not only streamlines operations but also ensures compliance with environmental standards. Additionally, explore partnerships with companies specializing in sustainable resource management to further enhance your operational sustainability.

The rapid evolution of programmable logic controllers (PLCs) has ushered in a new era of industrial safety and efficiency, particularly with the growing focus on cybersecurity enhancements. According to a recent report by MarketsandMarkets, the global industrial control systems (ICS) security market is projected to reach $18.6 billion by 2025, reflecting a compound annual growth rate of 10.2%. This surge indicates an increasing recognition of the importance of securing PLCs against sophisticated cyber threats, which can lead to operational downtime and significant financial losses.

Innovations in PLC cybersecurity are not just responding to immediate threats but are also paving the way for safer industrial environments. Advanced features such as real-time threat detection and automated response mechanisms are becoming standard in next-generation PLCs. A study by the International Society of Automation highlights that companies implementing robust cybersecurity measures in their industrial control systems can reduce the risk of successful cyberattacks by up to 80%. As industries continue to embrace the digital transformation, investments in secure PLC systems will be vital in protecting critical infrastructure from potential breaches and ensuring seamless operations.