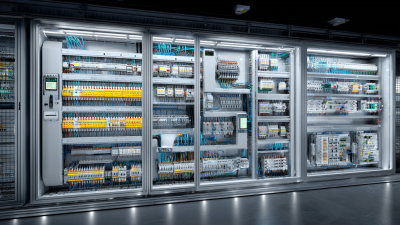

In the rapidly evolving landscape of modern industry, the integration of advanced technologies has become paramount for enhancing efficiency and productivity. At the forefront of this digital transformation are PLC control systems, which serve as the backbone of automation in various sectors. Renowned expert in industrial automation, Dr. John Smith, emphasizes the significance of this technology by stating, "PLC control systems are not just tools; they are the very foundation that drives intelligent manufacturing and operational excellence."

The evolution of Programmable Logic Controllers (PLCs) has been a cornerstone in modern industrial automation. According to a report by MarketsandMarkets, the global PLC market is projected to grow from USD 11.2 billion in 2020 to USD 15.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2%. This growth is indicative not only of expanding automation needs but also of the advancements in PLC technology that are revolutionizing various industries.

Modern industries are increasingly relying on PLC systems to enhance operational efficiency and flexibility. For instance, the integration of IoT with PLCs has allowed for real-time data collection and analysis, enabling predictive maintenance and reducing downtime. As highlighted in a study from Grand View Research, the adoption of IoT-enabled PLCs in manufacturing has already seen an increase of approximately 72% in the last three years. This shift is driving industries toward more intelligent and interconnected processes, ensuring that they can respond swiftly to market demands and remain competitive in a rapidly changing landscape.

Moreover, the incorporation of advanced programming languages and visualization tools has transformed PLCs into powerful controllers capable of managing complex processes seamlessly. The push towards Industry 4.0 further emphasizes the importance of PLCs as they adapt to handle higher-level tasks and integrate with cloud computing and AI. As industries continue to embrace these innovations, the future of PLC control systems looks brighter than ever, promising to unlock incredible potential across diverse sectors.

| Category | Description | Key Features | Adoption Rate (%) | Future Trends |

|---|---|---|---|---|

| Basic PLC Systems | Traditional PLC used for machine control and automation. | Simplicity, Robustness, Low Cost | 30% | Integration with IoT |

| Advanced PLC Systems | Enhanced PLCs with data acquisition and processing capabilities. | Data Logging, Advanced Diagnostics | 50% | AI Integration |

| Distributed Control Systems (DCS) | Control system that uses distributed architecture for complex processes. | Scalability, Flexibility, High Performance | 40% | Enhanced Cybersecurity |

| Programmable Automation Controllers (PAC) | Instrument combining the features of PLCs with those of PCs. | High Processing Power, Versatile Programming | 25% | Edge Computing Integration |

| Soft PLC Software Solutions | Software-based control solutions that run on hardware platforms. | Cost-effective, Flexible, Upgradable | 15% | Increased Integration with Cloud Services |

In 2025, the landscape of programmable logic controllers (PLCs) has evolved significantly, driven by rapid advancements in technology and the increasing demand for automation across various industries. According to a recent report by MarketsandMarkets, the PLC market is expected to reach USD 16.27 billion by 2025, growing at a CAGR of 6.6%. The integration of IoT capabilities into PLC systems has become a game-changer, allowing real-time data collection and remote monitoring, which enhances operational efficiency and predictive maintenance.

One notable innovation is the adoption of edge computing within PLC architecture, which allows for processing data close to its source. This minimizes latency and bandwidth issues, facilitating quicker decision-making processes. Additionally, the use of artificial intelligence and machine learning algorithms in PLC software enables advanced analytics and improved fault detection, further optimizing production lines. As industries continue to embrace Industry 4.0, these key features position top PLC solutions as essential components in achieving seamless and intelligent manufacturing environments.

The modern industrial landscape is rapidly evolving, with the integration of

Internet of Things (IoT) technologies

into Programmable Logic Controller (PLC)

systems transforming automation processes. By connecting PLCs to IoT devices,

manufacturers can achieve unprecedented levels of data collection and

real-time analytics. This combination allows for better monitoring of

equipment, predictive maintenance, and more efficient production workflows,

ultimately leading to reduced

downtime and increased

productivity.

As industries embrace these advanced technologies, the interoperability

between devices becomes crucial. IoT-enabled PLC systems facilitate seamless

communication across different layers of the manufacturing infrastructure,

providing operators with a holistic view of operations. Enhanced data visualization and

remote access to PLC settings empower engineers to make informed decisions quickly.

Moreover, the ability to analyze vast amounts of operational data enables businesses

to optimize their processes continuously, driving innovation and competitiveness in an

increasingly digital marketplace.

The rise of Programmable Logic Controllers (PLCs) has revolutionized industrial automation, demonstrating their pivotal role in enhancing operational efficiency. A recent report from MarketsandMarkets indicates that the PLC market is projected to grow from $9.6 billion in 2020 to $13.2 billion by 2025, highlighting the increasing adoption of advanced control systems in manufacturing and process industries. This growth is largely driven by the need for automation and data-driven decision-making in complex manufacturing environments.

Case studies from leading industries underscore the successful implementation of PLC systems. For example, an automotive manufacturer recently integrated PLCs into their production line, resulting in a 30% increase in productivity and a 20% reduction in downtime. Similarly, a food processing plant that adopted PLC technology saw significant improvements in quality control and compliance with safety regulations, with error rates decreasing by 15%. These examples not only illustrate the tangible benefits of PLC implementation but also reinforce the critical role of automation in optimizing production processes across various sectors.

The integration of artificial intelligence (AI) and machine learning into programmable logic controller (PLC) technology is revolutionizing industrial automation. These advanced technologies enhance the traditional capabilities of PLC systems, enabling more intelligent decision-making and adaptive process control. By analyzing vast amounts of data in real time, AI algorithms can identify patterns and anomalies that help in predictive maintenance, reducing downtime and increasing overall efficiency.

Moreover, machine learning facilitates the ability of PLCs to learn from operational data, allowing them to optimize production processes autonomously. As equipment operates, the system continuously refines its algorithms, leading to better resource management and reduced waste.

This dynamic functionality positions PLCs at the forefront of Industry 4.0 initiatives, where smart factories leverage interconnected systems to boost productivity and innovation. With further advancements on the horizon, AI and machine learning are set to play pivotal roles in shaping the future of PLC technology in various industrial sectors.