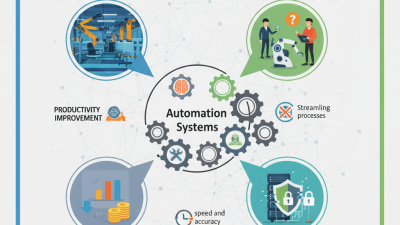

In 2026, the landscape of Automation Systems is set to transform industries dramatically. Experts like Dr. Emily Chen, a leader in automation technology, have emphasized, “The future of industries depends on how we adapt our automation systems.” This thought captures the essence of innovation in automation.

Industries are rapidly evolving, driven by cutting-edge automation trends. Predictive analytics, machine learning, and AI integration are redefining operational efficiency. These systems are not just about increasing speed; they are about enhancing decision-making processes. However, with this growth comes the challenge of adapting existing workflows.

Reflecting on these advancements, many organizations struggle to implement new automation systems effectively. There’s a fine line between embracing technology and maintaining human oversight. As we look ahead, understanding these dynamics will be crucial. The impact of automation on workforce dynamics and ethical considerations remains complex. The 2026 trends in automation systems will require deep reflection and thoughtful integration.

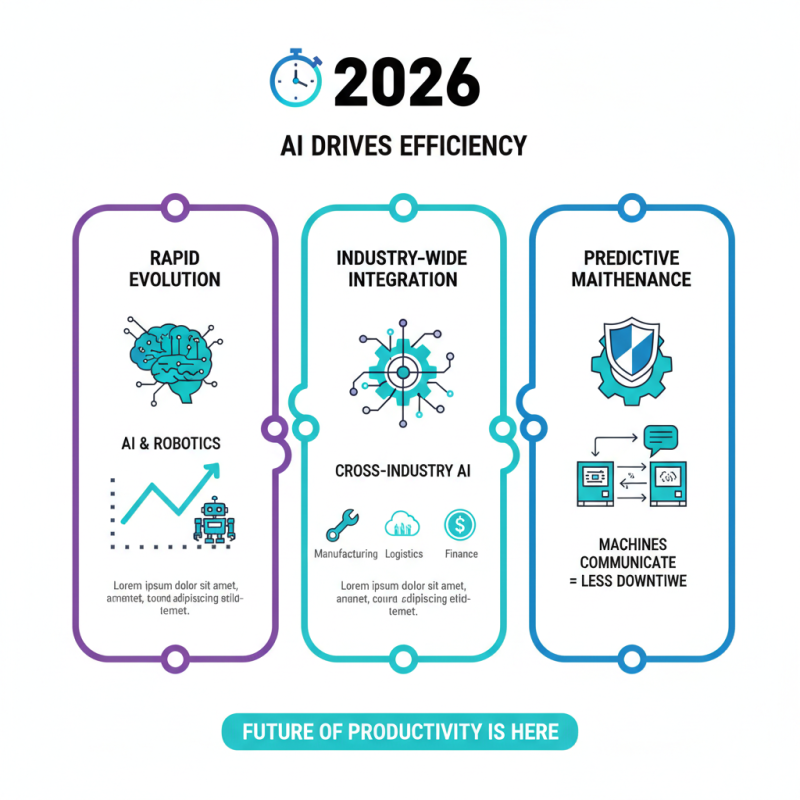

As we approach 2026, automation technologies are evolving rapidly. Innovations in artificial intelligence will drive efficiency across various industries. Companies will integrate AI-driven systems for predictive maintenance. This means machines will communicate their needs, reducing downtime effectively.

Additionally, robotics will become more accessible. Small businesses can adopt robotic solutions for tasks that require precision and speed. These robots may work alongside human workers in warehouses or production lines. However, as these technologies grow, concerns about job displacement will persist. People must reflect on how to balance automation with meaningful employment.

Moreover, advancements in IoT will enhance connectivity between devices. Smart sensors will enable real-time monitoring and data collection. Industries can analyze this data to improve processes and cut costs. Yet, with increased connectivity comes the risk of cyber threats. Ensuring cybersecurity alongside these innovations will be a key challenge. The road ahead is filled with potential, but also requires cautious navigation.

Artificial intelligence is transforming industrial automation. In recent studies, 70% of companies reported increased efficiency after implementing AI. This technology helps in predictive maintenance, reducing downtime substantially. For instance, AI algorithms analyze equipment data to predict failures before they occur. Consequently, this enhances productivity and lowers operational costs.

Another key area is collaboration between humans and machines. Reports indicate that 65% of the workforce believes AI will augment their skills. However, not everyone is adapting smoothly. Some workers express concerns about job displacement. Organizations must address these fears while promoting the benefits of AI integration.

Despite its advantages, the implementation of AI in automation isn't flawless. Technical glitches and data privacy issues remain significant challenges. A recent survey revealed that 40% of industries struggle with data security risks. Companies can improve their strategies by prioritizing employee training and cybersecurity measures. These steps are crucial for a balanced and effective adoption of AI in industrial automation.

Manufacturing processes are undergoing a significant transformation through emerging robotics solutions. These changes enhance productivity and efficiency across the board. Robots are now capable of performing complex tasks that once required human intervention. They assemble products, manage inventory, and ensure quality control. It’s remarkable how these machines can adapt to new patterns of work.

However, not all robots are perfect. Some can struggle with inconsistencies in materials or unexpected changes in production flow. These challenges can create delays and increase costs. Companies must continually assess and refine their robotic systems to overcome such issues. A balanced approach is essential to integrate robotics effectively into existing workflows.

Sustainability is another important aspect of this transformation. Robots can reduce waste and streamline resource use. Yet, the energy consumption of these systems is a growing concern. Manufacturers are encouraged to reflect on how robots impact both the environment and their bottom lines. It's crucial to ensure these advancements lead to a greener future while enhancing operational efficiency.

This chart illustrates the trend adoption rates for various automation systems in manufacturing as projected for 2026. Key trends include Robotics Integration and AI-Driven Analytics, which are expected to lead the way in transforming manufacturing processes.

The integration of the Internet of Things (IoT) in automation systems is reshaping industries. According to a recent report by Gartner, over 75% of organizations that implement IoT in automation see improvement in operational efficiency. Sensors and connected devices streamline processes and provide real-time insights. For instance, factories can monitor equipment health, leading to predictive maintenance and reduced downtime.

However, not every implementation is flawless. Some companies struggle with data overload. Too much information can lead to confusion rather than clarity. A study by McKinsey found that only 30% of firms achieve full benefits from their automated IoT initiatives. Lack of a clear strategy and skilled personnel can hinder progress. Moreover, cybersecurity concerns remain a significant barrier. As systems become interconnected, they can become vulnerable to attacks.

Yet, the potential rewards are impressive. Enhanced productivity and lower costs are enticing. A report from the International Data Corporation (IDC) predicts global spending on IoT will surpass $1.1 trillion by 2025. This boom reflects a growing recognition of the value IoT brings to automation. Nonetheless, industries must address challenges, ensuring a thoughtful approach to realize the true potential of these technologies.

| Trend | Description | Impact on Efficiency | Expected Growth (%) |

|---|---|---|---|

| Integration of IoT | Connecting devices to collect and analyze data for real-time insights | Increases operational efficiency by reducing downtime | 30% |

| AI and Machine Learning | Automating decision-making processes with predictive analytics | Enhances accuracy and optimizes resource allocation | 25% |

| Robotic Process Automation (RPA) | Automating routine tasks to free up human resources for complex jobs | Reduces processing time and minimizes errors | 40% |

| Cloud-Based Automation | Leveraging cloud technology for scalable automation solutions | Increases flexibility and reduces IT costs | 35% |

| Cybersecurity in Automation | Implementing robust security measures to protect automated systems | Ensures data integrity and minimizes disruption risks | 20% |

Sustainability is crucial for the future of automation systems. Many industries face pressure to reduce their environmental footprint. Automation technology can play a key role in achieving this goal. Companies are exploring new ways to use automation. This helps minimize waste and energy consumption.

Smart automation systems can analyze data in real-time. These systems can identify inefficiencies quickly. For instance, automated processes can optimize resource usage. This minimizes unnecessary waste. However, implementing these technologies is challenging. Not all businesses are ready to adapt. Some may struggle with the upfront costs.

**Tips**: Start small. Focus on areas where automation can make an immediate impact. Regularly review your systems. Identify potential improvements over time. Don’t expect immediate perfection. The transition to sustainable automation is a journey. Embrace the learning process. It's not just about technology; it's also about mindset.