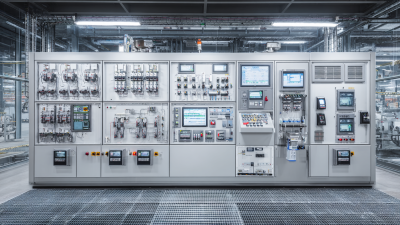

In today's fast-paced industrial landscape, the integration of Digital Control Systems (DCS System) has emerged as a pivotal strategy for enhancing operational efficiency and productivity. According to a report by Markets and Markets, the global DCS market is projected to grow from $19.8 billion in 2020 to $26.5 billion by 2025, reflecting an impressive CAGR of 5.8%. This growth underscores the increasing acceptance of DCS systems across various sectors, including oil and gas, pharmaceuticals, and manufacturing. By facilitating real-time monitoring and control of processes, DCS systems not only improve safety standards but also optimize resource utilization and reduce downtime. With the advent of Industry 4.0, the importance of DCS systems is further magnified as they integrate with emerging technologies like IoT and Big Data analytics, creating a robust framework for smarter, data-driven operations.

Assessing the need for a Distributed Control System (DCS) within an industry is a critical step in enhancing operational efficiency and maintaining competitiveness. The first factor to consider is the complexity of your processes. Industries with intricate operations, such as chemical manufacturing or oil refining, can significantly benefit from a DCS. These systems provide centralized control, facilitating real-time monitoring and enabling swift adjustments to maintain optimal conditions.

Another crucial aspect is the scalability of your operations. If your industry is experiencing growth or plans to expand in the future, implementing a DCS can accommodate increasing demands without sacrificing performance. Additionally, evaluating the current maintenance costs and system inefficiencies can indicate whether a DCS will yield a return on investment through reduced downtime and improved resource management. Engaging with stakeholders and conducting a thorough needs analysis will ensure that the decision to implement a DCS is aligned with the overall strategic goals of your organization.

| Dimension | Description | Advantages | Industries Benefitted |

|---|---|---|---|

| Cost Efficiency | Reduces operational costs through automation | Lower labor costs, reduced waste | Manufacturing, Energy |

| Data Integration | Centralizes data from various sources | Enhanced decision-making, real-time monitoring | Chemical, Pharmaceutical |

| Process Control | Improves consistency and quality of output | Increased product quality, fewer defects | Food & Beverage, Oil & Gas |

| Scalability | Easily adaptable to changes in production | Flexibility in response to market demands | Aerospace, Automotive |

| Safety and Compliance | Enhances workplace safety and regulatory compliance | Reduced accidents, improved compliance reporting | Mining, Water Treatment |

In the rapidly evolving landscape of modern industries, the implementation of Distributed Control Systems (DCS) has become crucial for enhancing operational efficiency and reliability. When evaluating key features of modern DCS solutions, companies should focus on several critical aspects. Firstly, the system's ability to facilitate seamless integration with existing infrastructure and technologies is vital. According to the International Society of Automation, 64% of organizations report achieving a significant reduction in downtime by utilizing advanced DCS solutions that integrate smoothly with their legacy systems.

Another essential feature to consider is the robustness of data analytics capabilities. Modern DCS systems offer real-time data processing and predictive analytics, which empower industries to make informed decisions rapidly. A recent report from McKinsey & Company highlights that organizations harnessing advanced analytics see a 20-30% improvement in operational performance metrics.

**Tip**: Always prioritize solutions that provide customizable dashboards and user-friendly interfaces, enabling operators to access critical data swiftly.

Additionally, scalability is a core attribute that should not be overlooked. Industries should select DCS solutions designed to grow alongside their operations, accommodating future technological advancements. Focusing on these features ensures that organizations not only stay competitive but also leverage the best of what modern DCS technology has to offer.

**Tip**: Conduct thorough vendor assessments to ensure they have a proven track record of supporting long-term scalability in dynamic industrial environments.

In today's rapidly evolving industrial landscape, the integration of Distributed Control Systems (DCS) with existing infrastructures is paramount for enhancing operational efficiency and productivity. According to recent analyses, companies that implement DCS solutions report up to a 25% reduction in operational costs, largely due to improved process optimization and real-time monitoring capabilities. For instance, Emerson's DeltaV Edge Environment 2.0 showcases advanced integration of operational technology that enhances data interoperability across platforms, allowing for seamless control and improved decision-making.

Achieving a smooth integration of DCS with legacy systems requires meticulous planning and execution. Organizations must prioritize data compatibility and the use of open communication protocols to ensure that new systems can communicate effectively with established infrastructures. The shift towards a single DCS platform, as demonstrated by companies like Dow, illustrates how a unified approach can streamline processes across global operations, resulting in enhanced efficiency and reliability. Additionally, consistent employee training and adapting workflows to accommodate new technologies play vital roles in a successful transition, ultimately guiding industries toward a more automated and intelligent future.

Training staff effectively for the utilization of Distributed Control System (DCS) technology is crucial as industries increasingly adopt these systems to enhance operational efficiency. According to a report by the International Society of Automation, nearly 60% of manufacturing firms note that proper training significantly boosts productivity and minimizes operational disruptions linked to system mismanagement. As DCS technology becomes more sophisticated, staff must be equipped not only with basic operational skills but also with a deep understanding of the software interfaces and analytical tools that accompany these systems.

Implementing a structured training program is essential. Industry studies, such as those from the ARC Advisory Group, indicate that organizations investing in comprehensive training programs see a 30% improvement in system performance. These programs should include hands-on training sessions, simulations, and continuous assessments to adapt to the evolving technology landscape. Additionally, fostering a culture of continuous learning will empower employees to engage with emerging features and operational strategies effectively, resulting in a more agile and responsive workforce.

Implementing a Distributed Control System (DCS) in modern industries can result in significant enhancements in operational efficiency and productivity. To accurately measure the Return on Investment (ROI) of a DCS system, companies should focus on quantifiable metrics such as reduced downtime, increased output, and improved energy efficiency. According to a recent report by the International Society of Automation, organizations can experience up to a 15% increase in production efficiency and a 20% decrease in operational costs following DCS implementation.

When assessing the ROI, it’s essential to take a holistic approach. Factors such as the reduction in maintenance costs, improved safety protocols, and enhanced regulatory compliance should also be included in the evaluation. A study by ARC Advisory Group indicates that a properly implemented DCS can shorten response times to process deviations by up to 50%, which directly influences profitability.

Tips: To effectively measure ROI, consider creating a baseline of current operational metrics prior to DCS implementation. Regularly review these metrics post-implementation to gauge improvements. Additionally, involve key stakeholders in the ROI assessment process to ensure that all applicable benefits are considered, enhancing the validity of your evaluation.