In today's fast-paced industrial landscape, maximizing operational efficiency while keeping costs in check is paramount for success. This is particularly crucial for manufacturers looking to maintain a competitive edge in a global market that increasingly values both quality and affordability. The emergence of advanced automation technologies has revolutionized how businesses approach production processes. Among these innovations, the Low Cost PLC With HMI stands out as a game changer, offering an economical solution without compromising on performance or reliability. By integrating these cost-effective systems, manufacturers can streamline their operations, enhance productivity, and improve overall output quality. As China continues to gain global respect for its manufacturing capabilities, leveraging the advantages of low-cost PLCs with HMIs can further empower local industries to unlock their full potential, driving innovation and competitiveness on the world stage.

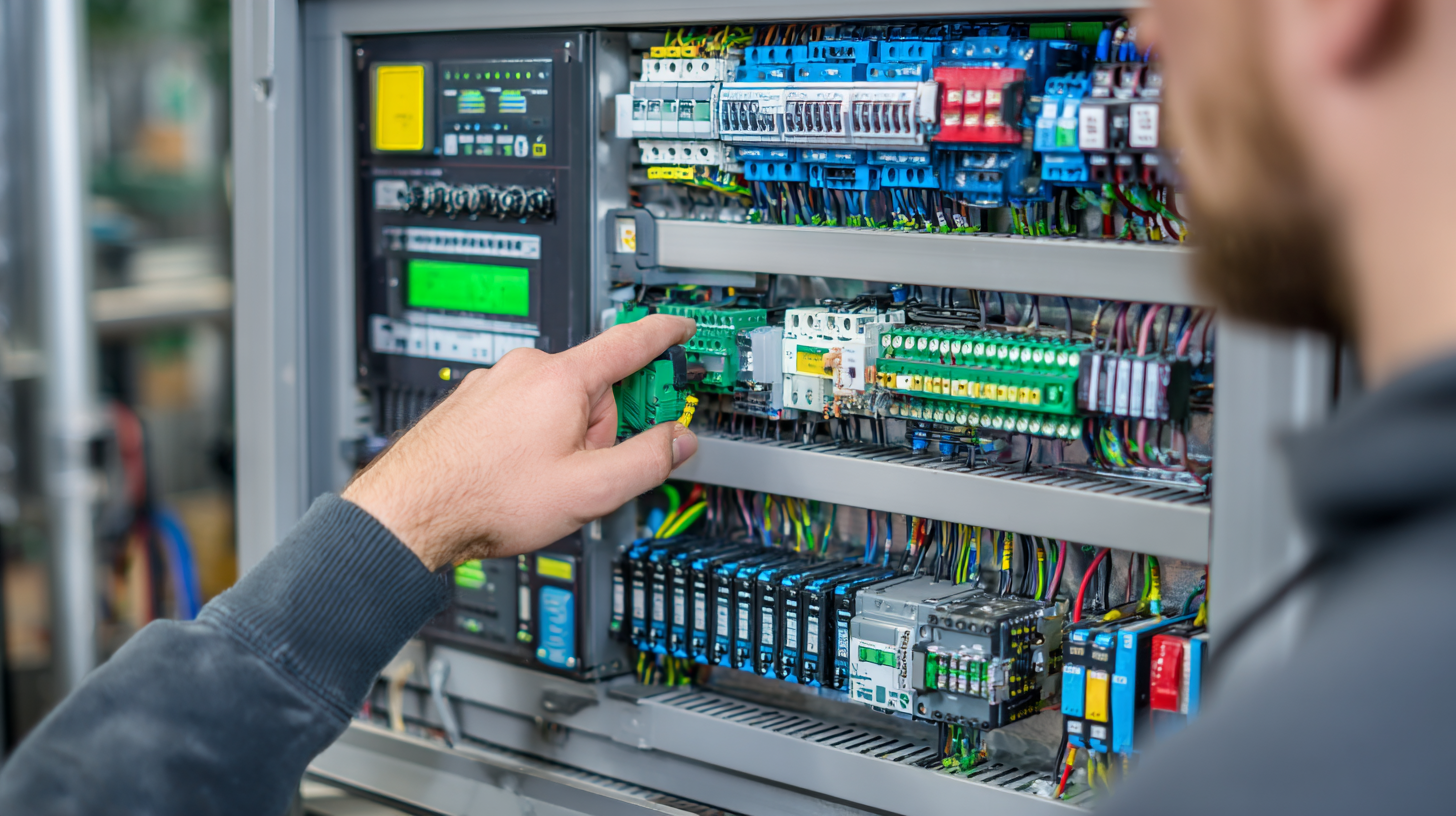

Low-cost PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces) have become essential components in modern industrial automation, significantly enhancing operational efficiency. A report by MarketsandMarkets predicts the global PLC market will reach $14.5 billion by 2023, reflecting the growing reliance on these technologies. Low-cost PLCs offer important features such as modular design, ease of programming, and compatibility with various communication protocols, which allow for seamless integration into existing systems. This versatility enables businesses to streamline operations, ultimately reducing downtime and operational costs.

When selecting a low-cost PLC, consider a few key features that can greatly enhance efficiency. First, prioritize models that support remote monitoring and control, which can lead to quicker response times and reduced labor costs. Additionally, look for PLCs with built-in data logging capabilities that facilitate real-time analytics. According to a recent study by ARC Advisory Group, companies implementing data-driven decision-making saw an average productivity increase of 15%.

Tip: Ensure your chosen HMI is user-friendly and supports customizable dashboards, allowing your team to visualize and interact with crucial data easily. Investing in the right low-cost PLC and HMI not only boosts productivity but also enhances the ability to adapt to changing operational needs.

In today's competitive landscape, optimizing operational expenses is critical for businesses aiming for sustainable growth. One of the most effective strategies is the implementation of low-cost Programmable Logic Controllers (PLCs) combined with Human-Machine Interfaces (HMIs), which can result in significant cost savings. According to a report from MarketsandMarkets, the global PLC market is expected to grow from $10.59 billion in 2020 to $16.10 billion by 2025, indicating a robust shift towards more affordable automated solutions. The integration of low-cost PLCs can reduce setup and maintenance expenses by up to 30%, allowing businesses to allocate resources more efficiently while maintaining high productivity levels.

Tips for maximizing the benefits of low-cost PLCs include thorough vendor research to find quality products that offer long-term support and scalability. Additionally, consider investing in training for your team to manage and troubleshoot these systems effectively, which can further minimize downtime and operational costs. Another strategy is to implement predictive maintenance through the use of integrated HMIs, which can help detect issues before they escalate, saving both time and money in the long run. By leveraging these tactics, organizations can not only enhance their operational efficiency but also position themselves favorably in an increasingly automated market.

In today's rapidly evolving production landscape, flexibility and scalability are paramount for maintaining competitive advantage. As traditional firms face pressing challenges, the integration of artificial intelligence (AI) and advanced manufacturing technologies is reshaping operational frameworks. Research indicates that businesses leveraging AI can enhance earnings before interest, taxes, depreciation, and amortization (EBITDA) through improved decision-making and resource allocation. This adaptation is particularly critical in environments where production needs frequently shift, necessitating agile responses to market demands.

To achieve optimal scalability, companies must embrace flexible technologies like low-cost PLCs paired with HMIs. These systems not only streamline operations but also enable swift adjustments to production levels and inventory management. In fact, supply chain flexibility can significantly improve a company's bottom line. Reports suggest that industries optimizing their supply chain configurations can achieve up to a 20% cost reduction and a corresponding increase in responsiveness to market changes.

**Tips:**

1. Invest in solutions that allow for easy upgrades and integrations to meet future demands.

2. Combine real-time data analytics with advanced automation to enhance decision-making and efficiency.

3. Foster a culture of flexibility within your workforce to adapt to new technologies and processes seamlessly.

| Feature | Description | Benefits | Use Case |

|---|---|---|---|

| Cost-Effectiveness | Affordable solution for automation needs. | Reduced initial investment and lower operational costs. | Small-scale manufacturing setups. |

| User-Friendly Interface | Intuitive HMI design for easy operation. | Reduced training time for operators. | Assembly lines and process industry. |

| Flexibility | Easily adapt to different production processes. | Ability to scale production up or down. | Batch processing and seasonal demand. |

| Scalability | Add-on modules for increased capabilities. | Support for growth without significant re-investments. | Expanding production lines. |

| Integration | Compatible with most existing systems. | Seamless addition to current setups. | Upgrading legacy systems. |

In today's fast-paced industrial environment, efficiency is key to maintaining a competitive edge. The integration of Human-Machine Interfaces (HMIs) with low-cost Programmable Logic Controllers (PLCs) plays a crucial role in streamlining operations. These user-friendly interfaces serve as the backbone of communication between operators and machinery, allowing real-time monitoring and control. By simplifying the interaction with complex systems, HMIs empower operators to make informed decisions swiftly, minimizing downtime and enhancing productivity.

Moreover, the intuitive design of modern HMIs caters to users with varying levels of technical expertise, making them accessible to a wider workforce. Operators can easily navigate through touchscreens, accessing vital data and system diagnostics at their fingertips. This ease of use not only speeds up training times but also reduces the likelihood of errors, which can be detrimental in a manufacturing setting. With clear visuals and interactive controls, HMIs facilitate a more engaged workforce, ensuring everyone is aligned with operational goals and performance metrics.

In today's fast-paced industrial landscape, the integration capabilities of low-cost PLCs (Programmable Logic Controllers) with HMI (Human-Machine Interface) systems are revolutionizing how businesses optimize their operations. These compact yet powerful systems provide seamless connectivity with various machinery and sensors, allowing for a more streamlined workflow. By enabling real-time data exchange and visualization, operators can make informed decisions quickly, enhancing overall efficiency in production processes.

Moreover, the affordability of these low-cost PLCs does not compromise their performance. Companies can achieve significant cost savings while maintaining robust integration capabilities, ultimately improving operational flexibility. With user-friendly interfaces, these systems empower staff at all levels to monitor and control processes effortlessly, reducing training time and minimizing the risk of errors. This integration of low-cost technologies into existing workflows not only leads to increased productivity but also positions businesses to respond agilely to market demands and changes.