In the realm of modern industries, the drive for efficiency is more critical than ever, and one company stands at the forefront of this transformation: Schneider PLC. As organizations seek to streamline operations and enhance productivity, the integration of automation technology is proving to be a game changer. This article delves into how Schneider PLC not only simplifies complex processes but also empowers businesses to make informed decisions through real-time data and analytics.

From manufacturing plants to energy management systems, the versatility of Schneider PLC solutions showcases their pivotal role in unlocking automation. Join us as we explore the various strategies and methods to harness the full potential of Schneider PLC, ultimately leading to a more efficient and innovative industrial landscape.

The evolution of PLC technology in the context of Industry 4.0 marks a significant transformation in automated processes across various sectors. Traditionally, Programmable Logic Controllers (PLCs) were utilized primarily for basic control tasks in manufacturing environments. However, with the advent of Industry 4.0, which emphasizes connectivity and data exchange, PLCs have undergone substantial advancements. Modern PLCs are now equipped with capabilities to interface seamlessly with IoT devices, allowing for real-time data collection, monitoring, and analysis.

As industries strive for greater efficiency and flexibility, the integration of advanced PLC technology is crucial. These smart controllers can now utilize artificial intelligence and machine learning algorithms to optimize operations, predict maintenance needs, and minimize downtime. This shift not only enhances operational efficiency but also empowers businesses to swiftly adapt to changing market demands. Consequently, the evolution of PLCs symbolizes a foundational element in achieving automation goals and driving the digital transformation of modern industries.

| Industry | PLC Application | Efficiency Improvement (%) | Key Technologies |

|---|---|---|---|

| Manufacturing | Automated Assembly Lines | 20% | IoT Integration, AI Algorithms |

| Food Processing | Batch Processing Control | 15% | Temperature Sensors, Data Analytics |

| Automotive | Robotic Welding | 25% | Machine Learning, Predictive Maintenance |

| Pharmaceutical | Continuous Manufacturing | 30% | Real-time Monitoring, Compliance Tracking |

| Energy | Smart Grid Management | 18% | Distributed Energy Resource, Data Analytics |

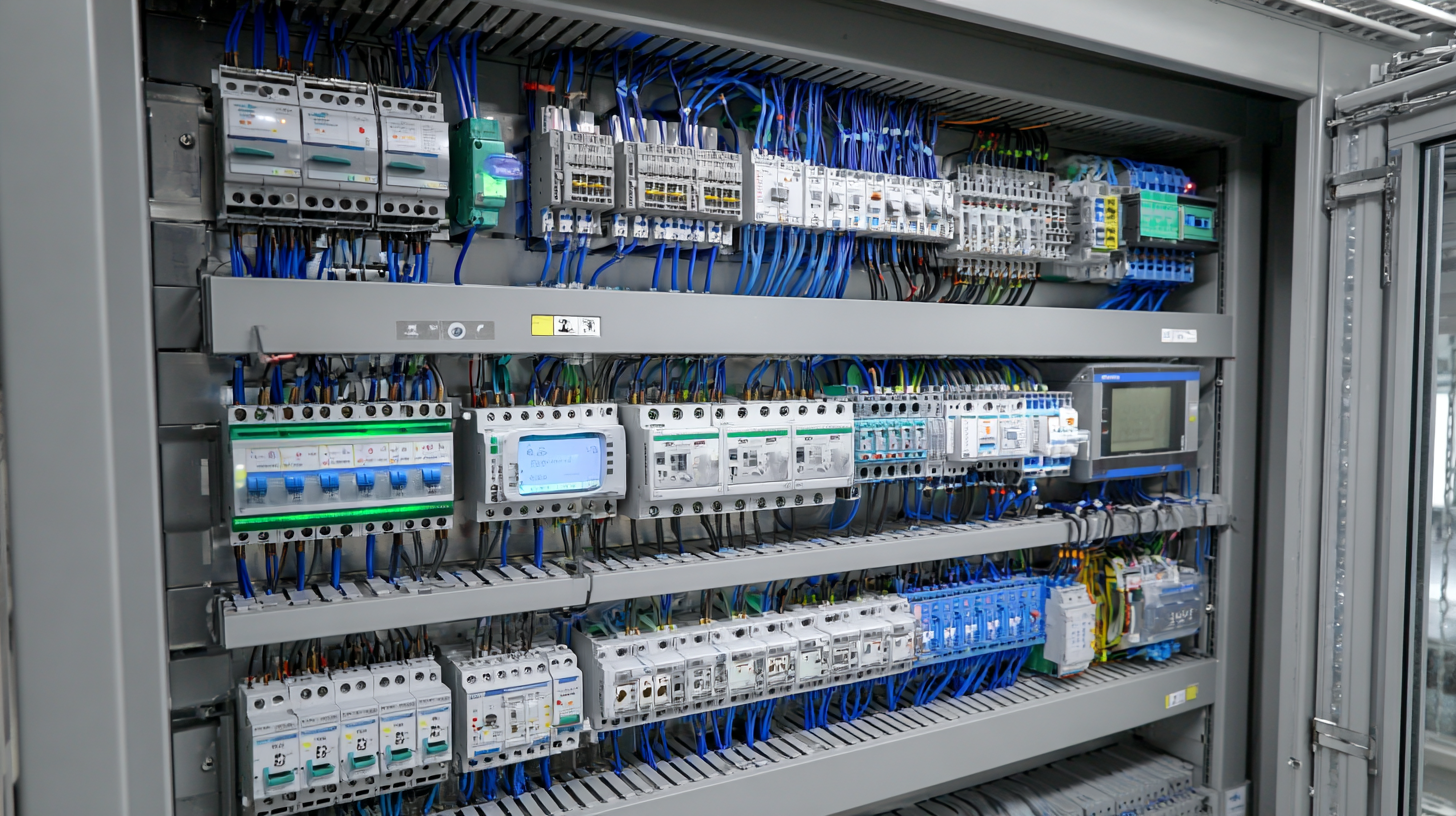

The integration of Programmable Logic Controllers (PLCs) into smart manufacturing systems is transforming the industrial automation landscape. As industries evolve towards more sophisticated and interconnected operations, PLCs play a pivotal role in enhancing efficiency, precision, and responsiveness. The current market for virtual and software-based PLCs is valued at approximately $865 million, with an expected compound annual growth rate exceeding 13% between 2024 and 2032. This growth is propelling the shift towards Industry 4.0 and intelligent manufacturing, where automation and data connectivity are paramount.

In this context, industries like lithium battery manufacturing are moving from mere scale expansion to a phase driven by technology and ecological collaboration. Schneider's presence at significant industry events underscores its commitment to advancing high-quality development in sectors like lithium with a focus on smart, green, and digital solutions. The ability of Schneider PLCs to seamlessly integrate into existing systems enables manufacturers to leverage automation effectively, optimize production processes, and ensure sustainability compliance, aligning with the broader goals of modern industrial paradigms.

In today’s fast-paced industrial landscape, operational efficiency is paramount for businesses aiming to maintain competitiveness and profitability. Schneider Electric’s Programmable Logic Controllers (PLCs) play a pivotal role in enhancing operational efficiency through advanced automation solutions. By integrating Schneider PLCs, industries can streamline processes, reduce human error, and improve resource management, ultimately leading to significant time and cost savings.

Automation enables real-time data monitoring and control, which empowers operators to make informed decisions swiftly. Schneider PLCs facilitate seamless communication between machines and systems, thus optimizing production lines and minimizing downtime. This high level of automation not only accelerates processes but also enhances the overall quality of output, ensuring that industries can meet customer demands promptly and effectively. Embracing Schneider’s automation solutions means embracing a future where operational efficiency is not just a goal, but a reality.

Real-time data analytics has revolutionized the landscape of modern industries, significantly enhancing production efficiency. By leveraging advanced data processing technologies, companies can monitor operations continuously, thereby identifying bottlenecks and inefficiencies without delay. Schneider PLC, with its robust automation solutions, integrates real-time data analytics to empower manufacturers to make informed decisions instantly. This capability not only optimizes machine performance but also improves overall workflow, reducing unnecessary downtime.

The impact of real-time data analytics extends beyond mere operational improvements. By analyzing data as it is generated, industries can adapt to changing conditions swiftly, leading to enhanced predictive maintenance strategies. For instance, Schneider PLC's systems can forecast potential equipment malfunctions, allowing companies to schedule maintenance proactively and minimize production interruptions. This proactive approach not only maximizes resource utilization but also drives significant cost savings, enabling businesses to operate at peak efficiency in a highly competitive market environment.

Schneider Electric's programmable logic controllers (PLCs) have made a significant impact across diverse industries by enhancing automation and operational efficiency. In manufacturing, for example, a leading automotive company implemented Schneider PLCs to streamline its assembly line processes. By integrating these advanced controllers, the company achieved a remarkable reduction in downtime and improved product quality, resulting in a shorter time-to-market for new models. The adaptability of Schneider PLCs allowed for real-time monitoring and control, facilitating quick responses to any production anomalies.

In the energy sector, a renewable energy firm utilized Schneider PLCs to optimize the management of wind farms. These controllers enabled precise monitoring of turbine performance and energy output, leading to better resource allocation and maintenance scheduling. The real-time data analytics provided by the PLCs minimized operational risks and maximized energy efficiency, significantly boosting the overall productivity of the wind farm. Such successful implementations reflect the versatility of Schneider PLCs in addressing the unique challenges faced by various sectors.