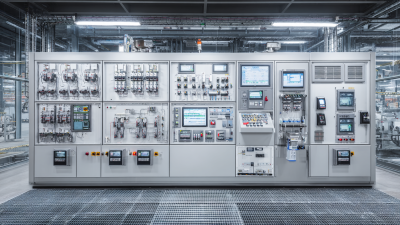

The integration of a DCS Control System has revolutionized the landscape of industrial automation, providing significant enhancements in process management and operational efficiency. According to a report by MarketsandMarkets, the global distributed control systems market is projected to reach USD 27.29 billion by 2025, growing at a CAGR of 6.9% from 2020. This growth highlights the escalating reliance on sophisticated automation solutions across various industries, including oil and gas, chemicals, and pharmaceuticals.

Experts in the field, such as Dr. Emily Carter, a leading authority on industrial automation technologies, emphasize the transformative impact of DCS. She states, “The DCS Control System not only streamlines operations but also fosters real-time data handling and agile response to dynamic process conditions.” As industries continue to evolve, leveraging such advanced systems becomes paramount in achieving optimal productivity and sustainability.

The benefits of DCS are manifold, from enhanced control and monitoring to better resource management, and these advantages make it an indispensable tool in today’s industrial landscape.

The enhanced process control offered by Distributed Control Systems (DCS) significantly elevates the efficiency and reliability of industrial automation. DCS enables precise monitoring and control of processes through advanced sensory technology and real-time data analytics. This capability ensures that processes run smoothly, minimizing variances that could lead to inefficiencies or product quality issues. By maintaining strict control over operational parameters, DCS helps industries reduce waste and optimize resources, directly contributing to improved productivity.

Moreover, DCS systems facilitate better decision-making through comprehensive data integration and visualization. Operators can access critical information through intuitive interfaces, allowing for swift adjustments to be made in response to changing conditions. This real-time visibility aids in identifying potential issues before they escalate, ultimately reducing downtime and maintenance costs. The ability to automate routine tasks frees up personnel to focus on more strategic initiatives, thereby enhancing overall operational effectiveness. With these advantages, DCS systems represent a key investment for companies seeking to advance their industrial automation capabilities.

This bar chart illustrates the top benefits of using DCS (Distributed Control System) for industrial automation, highlighting key advantages such as improved process control, enhanced efficiency, and better data management.

Real-time monitoring capabilities in Distributed Control Systems (DCS) have revolutionized industrial automation, providing facilities with the ability to monitor processes continuously and respond promptly to anomalies. According to a report by Research and Markets, the global DCS market is expected to grow by over 5% annually, driven largely by increasing demands for real-time data and analytics in manufacturing. This increased focus on real-time capabilities allows operators to make informed decisions and optimize processes effectively, thus enhancing operational efficiency.

Improved data management is another critical advantage of using DCS in industrial environments. By centralizing data from various sources, DCS enables better analysis and utilization of information across departments. A study conducted by the International Society of Automation found that companies implementing DCS experience a reduction in operational costs by approximately 20% due to enhanced data flow and minimized downtime. With advanced algorithms and machine learning integrated into modern DCS platforms, facilities can predict equipment failures before they occur, ensuring that maintenance is proactive rather than reactive. This leads to not only cost savings but also higher productivity levels overall.

The integration of Distributed Control Systems (DCS) into existing industrial equipment presents significant advantages, particularly in enhancing operational efficiency. By facilitating seamless connections between new and legacy systems, DCS allows for more precise monitoring and control of various processes, ultimately resulting in a streamlined workflow. This is particularly evident in critical sectors such as power generation, where organizations can repurpose older coal plants with advanced technologies for improved output and sustainability.

Moreover, the role of artificial intelligence in this context cannot be overlooked. As industries adopt AI-powered solutions, they can optimize processes further, leveraging predictive analytics to foresee maintenance needs and operational hiccups. This integration not only ensures that equipment works seamlessly together but also empowers businesses to make data-driven decisions, enhancing overall productivity. As seen in recent trends across various sectors, this synergy between DCS and modern technologies represents a pivotal step towards a more automated and efficient industrial landscape.

| Benefit | Description |

|---|---|

| Enhanced Efficiency | Optimizes production processes by reducing downtime and improving equipment performance. |

| Cost Savings | Lowers operational costs through better resource management and reduced waste. |

| Scalability | Facilitates the addition of new equipment and processes without major system overhauls. |

| Improved Data Collection | Provides comprehensive data analytics for better decision-making and forecasting. |

| Flexibility | Allows integration with a wide range of equipment and technologies. |

| Enhanced Safety | Improves workplace safety through enhanced monitoring and control mechanisms. |

| Simplified Maintenance | Easier diagnostics and troubleshooting extend equipment life and reduce maintenance costs. |

| Regulatory Compliance | Simplifies the tracking and reporting needed for compliance with industry regulations. |

| Real-Time Monitoring | Enables live tracking of operations which assists in quick problem resolution. |

| Better Collaboration | Enhances communication among teams through centralized data access and reporting. |

The integration of Distributed Control Systems (DCS) in industrial automation significantly enhances operational efficiency while simultaneously reducing downtime. DCS enables real-time monitoring and control of industrial processes, streamlining operations and minimizing interruptions. By utilizing advanced data analytics, facilities can predict when equipment is likely to fail, allowing for timely maintenance interventions. This predictive maintenance approach not only minimizes unplanned downtimes but also optimizes the overall operational workflow.

Moreover, the adoption of AI-driven solutions within DCS frameworks further amplifies these benefits. With AI's capability to analyze large datasets and identify patterns, industries can achieve unprecedented levels of operational reliability. In sectors such as manufacturing and automotive, implementing these smart maintenance strategies can lead to significant cost reductions and enhanced safety metrics. The focus on sustainable and efficient operations is vital as businesses strive to meet the evolving demands of the market while improving their bottom lines.

The integration of Distributed Control Systems (DCS) in industrial automation significantly enhances security features crucial for safeguarding sensitive operational data. In today's interconnected environments, where cyber threats are rampant, DCS control systems are designed with layered security protocols. These systems commonly implement advanced encryption for data transmission, preventing unauthorized access and ensuring that only verified personnel can modify operational parameters. By utilizing secure login processes and user authentication, companies can mitigate the risk of insider threats and protect their intellectual property.

Moreover, DCS systems often include real-time monitoring tools that constantly assess the security landscape within the industrial environment. This proactive approach not only identifies potential vulnerabilities but also allows for immediate responses to security breaches. The ability to log and audit user actions adds an additional layer of accountability, making it easier to trace the origins of any security incidents. Collectively, these robust security features not only shield industrial operations from external attacks but also cultivate a culture of safety and integrity within the organization, fostering confidence among stakeholders.