In today’s rapidly evolving industrial landscape, companies like Emerson Plc face a myriad of challenges that threaten operational efficiency and competitiveness. According to a recent report by MarketsandMarkets, the global industrial automation market is projected to reach $300 billion by 2026, highlighting the pressing necessity for companies to integrate advanced technologies to stay relevant. Emerson Plc, a leader in automation solutions, encounters obstacles such as fluctuating market demands, the integration of IoT technologies, and the pressure for sustainable practices. Furthermore, a Deloitte study emphasizes that 70% of organizations are struggling to adapt to digital transformations, underscoring the critical need for innovative solutions. This blog will explore the specific challenges faced by Emerson Plc and the strategic approaches the company is implementing to address these complexities effectively.

Emerson Plc operates in a complex landscape characterized by various operational challenges and dynamic market conditions. Recent trends in the building products market reveal significant growth prospects and strategic shifts in business operations. For instance, the global industrial valve market is projected to burgeon from approximately $95.58 billion in 2024 to over $121.67 billion by 2030, indicating heightened demand for automation and measurement technologies, sectors where Emerson excels.

Moreover, the company's commitment to innovation is reflected in its substantial investments—over $40 billion in acquisitions over four years—to enhance its capabilities. Emerson's unveiling of Project Beyond aims to establish a future-ready enterprise operations platform, addressing the need for enhanced operational efficiency and interoperability in automation. The industry has shown that operational efficiency is critical, particularly in emerging markets like Saudi Arabia, where the LED lighting sector is expected to soar from $832.18 million in 2024 to $1.83 billion by 2033.

As Emerson navigates these intricate market dynamics, it continues to outperform expectations. Recent earnings reports demonstrate robust financial health, with the company achieving an adjusted EPS of $1.48, surpassing market forecasts. These advancements position Emerson as a pivotal player in driving growth and innovation within the industry, illustrating its ability to adapt and thrive amidst evolving challenges.

Emerson Plc is navigating a complex competitive landscape in the smart manufacturing market, which is projected to reach a value of over $400 billion by 2025. Key components driving this growth include innovative solutions and services that cater to a range of deployment models, such as cloud and on-premises options. Industry reports indicate that cloud-based solutions are particularly gaining traction due to their scalability and cost-effectiveness, with businesses increasingly opting for these models to enhance operational efficiency and reduce overheads.

Moreover, the SCADA market is also on an upward trend, expected to grow significantly by 2032. Analysis shows that the demand for advanced supervisory control and data acquisition systems will surge as industries seek to improve automation and data collection processes. Emerson, along with its competitors, is strategically positioning itself through a robust portfolio of hardware and software offerings to capture market share. With over 4,000 global industrial automation projects documented, understanding the vendor footprints of major players is crucial. Emerson's innovative solutions are crucial in optimizing operational processes across various sectors, setting the stage for sustained growth and competitive advantage.

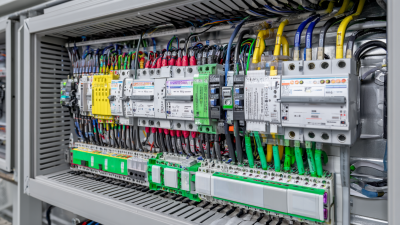

Emerson Plc has faced a myriad of operational challenges that have necessitated a robust response, particularly in the realm of digital transformation. The integration of advanced technologies is critical for enhancing operational efficiency and ensuring competitiveness in a rapidly evolving market. By leveraging the Internet of Things (IoT) and artificial intelligence (AI), Emerson can streamline processes, optimize supply chains, and enable real-time data analytics. This shift not only reduces operational costs but also improves product quality and responsiveness to customer needs.

Implementing digital solutions requires a strategic approach that emphasizes employee training and collaboration. Emerson must invest in upskilling its workforce to embrace new digital tools, ensuring that employees are equipped to navigate technological changes effectively. Additionally, fostering a culture of innovation and agility within the organization can facilitate smoother transitions and encourage proactive problem-solving. This holistic approach to digital transformation can ultimately empower Emerson to overcome its operational hurdles and position itself for sustained success in the global marketplace.

Emerson Plc is navigating a landscape filled with challenges that arise from evolving market demands and technological advancements. To remain competitive, the company has recognized the vital role that innovation plays in overcoming these obstacles. By leveraging cutting-edge technology, Emerson is not only enhancing operational efficiency but also driving its commitment to sustainability. This move to integrate advanced tools such as IoT and AI into their systems allows for real-time data analysis and predictive maintenance, ultimately leading to reduced downtime and increased productivity.

Moreover, embracing technology has empowered Emerson to streamline processes and improve collaboration across different departments. Through automation and smart technologies, teams are able to work in synergy to address issues more quickly and effectively. Introducing advanced manufacturing techniques and digital workflows has significantly improved the company’s overall responsiveness to market changes. These innovative solutions not only optimize resource utilization but also bolster Emerson's positioning as a leader in its industry, highlighting the importance of technology in solving contemporary business challenges.

| Challenge | Impact | Technology Solution | Expected Outcome |

|---|---|---|---|

| Inefficient Processes | Increased operational costs and delays | Automation Software | Reduced costs and enhanced productivity |

| Data Silos | Poor decision-making due to lack of insights | Integrated Data Analytics Tools | Improved analytics for better decisions |

| Supply Chain Visibility | Long lead times and stock inaccuracies | IoT Sensors and Tracking Systems | Enhanced visibility and reduced lead times |

| Employee Engagement | Low morale and high turnover rates | Collaboration Platforms | Increased employee satisfaction and retention |

The future outlook for Emerson Plc is closely tied to the evolving dynamics of the global machinery and industrial automation sectors. According to a market research report by Custom Market Insights, the global machinery and industrial automation market is projected to reach a staggering USD 407.4 billion by 2032, growing at a compound annual growth rate (CAGR) of 8.2%. This robust growth is indicative of the accelerating demand for automation solutions across various industries, including oil and gas, HVAC, and more.

In the oil and gas sector, the market for automation and instrumentation is anticipated to grow from its current valuation of USD 19.79 billion by 2028, with a CAGR of 3.30%. This growth is largely fueled by the increasing need for safety, efficiency, and regulatory compliance within this critical industry. Meanwhile, the HVAC market is also on an upward trajectory, with expectations of a USD 74.02 billion increase from 2023 to 2028. The surge in construction activities and heightened demand for energy-efficient systems are primary drivers of this growth, highlighting the opportunities Emerson Plc can leverage in the coming years to enhance its competitive advantage and market share.