Choosing the right industrial automation solutions can be a daunting task. Emerson Industrial Automation offers a variety of options tailored for diverse industries. “In automation, the right choice can drive efficiency,” says Dr. Jane Thompson, a leading expert in industrial automation technologies.

When considering Emerson Industrial Automation, businesses must assess their unique needs. This includes evaluating production demands and integration capabilities. Some companies overlook the importance of scalability, which can limit future growth. Automation should not just solve today’s problems. It must anticipate tomorrow’s challenges.

Finally, engaging with Emerson’s team can provide valuable insights. They guide businesses in identifying the best solutions. However, many organizations fail to involve their staff in this process. This can lead to misalignment and ineffective implementation. Making informed decisions about Emerson Industrial Automation is crucial for sustainable success.

Industrial automation is revolutionizing how businesses operate. A report from the International Federation of Robotics states that industrial robot installations have increased by 12% globally from 2020 to 2022. This uptick highlights the growing reliance on automation to boost productivity and efficiency. Companies often witness significant reductions in operational costs. However, the transition to automation is not without challenges.

Understanding the importance of industrial automation means recognizing its impact on workforce dynamics. Implementing automation can lead to job displacement, sparking concerns among employees. Additionally, while automation can optimize processes, it may require substantial upfront investment. Many businesses struggle with choosing the right automation solutions tailored to their unique needs. A balance must be struck between technology adoption and workforce training.

Moreover, successful integration of automation often demands ongoing evaluation. Businesses must assess whether their automation strategies yield the desired results. In a 2021 study from McKinsey, 45% of companies reported mixed outcomes from their automation efforts. This underscores the need for a thoughtful approach. Simply implementing technology is not enough; businesses must continuously adapt and refine their strategies to harness the full potential of industrial automation.

Identifying your business needs for automation requires a clear understanding of your operational goals. According to various industry reports, nearly 70% of businesses that prioritize automation see productivity gains within the first year. This highlights the potential of automation to streamline processes and increase efficiency. However, knowing what to automate is crucial. Not every task is suitable for automation, and this can lead to wasted resources.

Consider areas where repetitive tasks consume significant time. Data entry, inventory management, and service requests can burden employees. In fact, about 30% of workers spend most of their time on these mundane tasks. By targeting these specific pain points, businesses can make impactful strides. But it is essential to assess the costs. Automation solutions can be expensive and not all yield a strong return on investment.

The goals should align with the company's vision. What are your long-term objectives? Is it to reduce errors, enhance customer service, or cut costs? A mismatch in automation goals could lead to frustration. Companies should analyze their unique workflows before implementation. Regular reviews and adjustments are necessary to ensure the automation process remains effective. Balancing ambition with realistic expectations can transform your business functions positively.

When selecting industrial automation solutions, it’s crucial to understand available product offerings. Various products serve specific needs in different industries. These offerings include control systems, valves, and measurement devices. Each plays a unique role in improving efficiency and productivity. Consider how each system integrates with your current setup. Sometimes, compatibility is overlooked, leading to integration hurdles later.

Exploring specific solutions can help businesses make informed decisions. For instance, advanced control systems streamline processes. They allow for real-time monitoring and data analysis. This can save time and reduce errors in production. Many businesses hesitate to fully adopt new technologies. Fear of change can hinder progress, creating gaps in operational efficiency.

Measurement devices are also essential. They ensure accuracy in processes, from temperature control to flow rates. However, businesses must regularly evaluate these devices. Obsolete equipment can lead to increased costs. Identifying when to upgrade is challenging. Continuous assessment is necessary to maintain optimal performance.

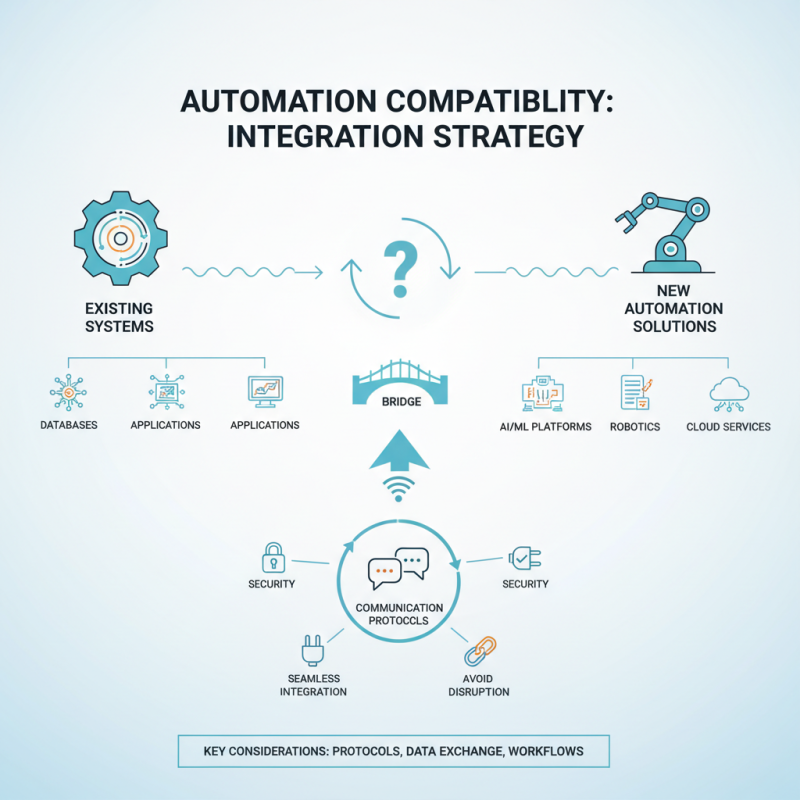

When selecting automation solutions, compatibility is crucial. Existing systems can have many complexities. It is important to assess how new technologies will fit into your current infrastructure. Consider the communication protocols you currently use. Can the new solution seamlessly integrate with these protocols? Analyzing this aspect helps avoid disruptions.

Integration is not just about connectivity. It's also about functionality. The new solution should enhance your operations without causing confusion. Test the solution in a controlled environment first. This gives you a glimpse of potential challenges. You might face unexpected glitches. Be prepared to adjust your existing processes as needed.

Sometimes, even minor incompatibilities can lead to significant issues. Look for solutions that offer flexibility in integration. Review case studies or ask for demonstrations. Understand that what works for one business may not work for another. Reflection on your unique environment is key when making your choice. Embrace the learning curve that comes with new technology.

When evaluating automation solutions, cost and ROI play pivotal roles. Businesses often overlook hidden costs. Frequent maintenance can escalate expenses, eating into profitability. Initial costs may seem manageable, but total expenditures must be assessed. Analyze warranties and support services, as these affect long-term spending.

Understanding ROI requires careful consideration of projected outputs. Short-term gains might appear enticing, but focus on long-term benefits. Consider how a solution enhances productivity. A system that minimizes downtime adds value. Yet, measuring real impact can be challenging. Organizations need to create benchmarks to track improvements accurately.

Investing in automation is not just a financial decision. It's about aligning technology with business goals. Commit to regular assessments to refine strategies. Sometimes, a less expensive option offers greater flexibility. This constant re-evaluation can lead to unexpected insights. Always keep an eye on the evolving market trends to stay competitive.