In today's rapidly evolving industrial landscape, the integration of automation technologies is no longer a luxury but a necessity for improving operational efficiency and competitiveness. According to a recent report by the International Society of Automation, the global industrial automation market is projected to reach $300 billion by 2025, driven by the increasing demand for smarter manufacturing processes.

One critical component of this automation revolution is the adoption of Low Cost PLCs with HMI (Human-Machine Interface), which offer enterprises an affordable yet effective solution for controlling and monitoring industrial processes. These systems simplify complex operations, increase productivity, and provide real-time data access, making them indispensable for manufacturers looking to optimize their workflows without heavy investments.

As we explore the key factors in selecting the right Low Cost PLC with HMI for your automation needs, we will delve into various considerations that can significantly influence your operational success and return on investment.

In industrial automation, understanding the basics of

Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) is crucial for selecting the right low-cost options to meet operational needs. PLCs act as the brain of automated processes, with capabilities to monitor inputs and control outputs, whereas HMIs provide users with a graphical interface to interact with machines.

As the global industrial automation market is set to grow from $134.6 billion in 2024 to an estimated $403.08 billion by 2033, with a compound annual growth rate of 8.5%, the demand for effective PLC and HMI solutions is ever-increasing.

In this landscape, the importance of advanced technologies such as cloud-native databases and smart applications enhances the functionality of PLCs and HMIs, ensuring stable growth in these markets. The data from recent reports highlight that key economic regions, including the U.S., Europe, and Japan, continue to maintain high demand for these automation technologies. Moreover, the integration of innovative systems, as seen in various showcases like trade fairs, underscores the push towards more intelligent manufacturing scenarios, directly influencing the effectiveness and efficiency of industrial operations.

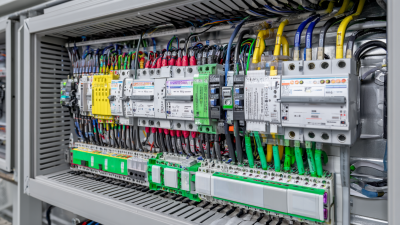

When selecting a low-cost PLC (Programmable Logic Controller) with HMI (Human-Machine Interface) for your industrial automation needs, several key factors must be evaluated to ensure optimal performance and cost-effectiveness. First, consider the processing power and memory of the PLC. According to a recent industry report by ARC Advisory Group, PLCs with adequate processing capabilities can enhance system reliability and efficiency, which is essential for handling complex tasks in automation systems.

Another critical factor is the communication capabilities of the PLC. Many low-cost options support standardized protocols like Ethernet/IP and Modbus, facilitating integration with existing systems. A report from Research and Markets indicates that the rise of the Industrial Internet of Things (IIoT) emphasizes the need for seamless connectivity, making this feature indispensable in modern automation environments.

Tips: Before making your selection, assess the scalability of the PLC system. As your automation needs grow, will the PLC be able to adapt? Additionally, consider the availability of technical support and user-friendly programming software. Investing in a controller that provides comprehensive support and easy programming can significantly reduce downtime and improve productivity in the long run.

When selecting a low-cost PLC with HMI for your industrial automation needs, prioritizing user-friendly HMI options is crucial for facilitating seamless interactions between operators and machines. As the integration of robotics in industrial settings increases, enhancing user experience becomes imperative. According to recent studies, companies that adopt effective human-robot interaction heuristics can see productivity improvements of up to 30%. The development of intuitive interfaces not only accelerates training but also reduces operational errors, fostering a smoother workflow.

To achieve this, consider incorporating touch-screen HMIs that offer clear visual feedback and easy navigation. Ensure that the HMI supports customizable dashboards, allowing operators to tailor the interface to their specific tasks. Additionally, implementing user-centric design principles can significantly enhance usability, ensuring that operators can interact effortlessly with robotic systems.

Tips for improving HMI usability include conducting regular user testing sessions to gather feedback, investing in training programs that enhance operator familiarity with the system, and opting for HMIs that feature easily readable fonts and colors. Emphasizing these aspects will not only improve interaction satisfaction but also empower your workforce to maximize the efficiency of your automated processes.

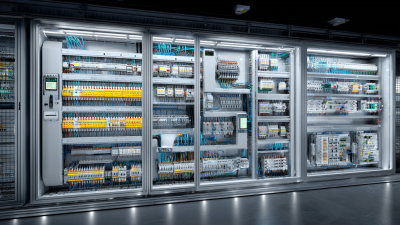

When selecting a low-cost PLC with HMI for your industrial automation needs, integration capabilities should be a primary focus. Ensuring compatibility with existing systems not only streamlines the implementation process but also minimizes operational disruptions. A PLC with robust integration features can communicate seamlessly with various devices and software, allowing you to harness the full potential of your automation system. This is crucial in today's manufacturing landscapes, where diverse technologies need to coexist and collaborate efficiently.

Recent advancements in technology, such as universal compatibility solutions in various sectors, demonstrate the importance of an adaptable approach. Just as some platforms enable AI agents to work across different frameworks, your PLC and HMI choice should support multiple protocols and interfaces. This ensures that your investment remains relevant as technologies evolve, ultimately providing a future-proof solution that can easily incorporate new functionalities while maintaining harmony with legacy systems. Prioritizing integration will not only enhance productivity but also facilitate smoother upgrades and expansions down the line.

| Criteria | Description | Compatibility | Cost | Integration Type |

|---|---|---|---|---|

| Communication Protocols | Supports various protocols like Modbus, Ethernet/IP | High | $300 | Wired |

| Input/Output Options | Number and type of I/O available | Medium | $250 | Modular |

| User Interface | HMI screen size and usability | High | $400 | Touchscreen |

| Software Support | Availability of programming software | High | $150 | PC-based |

When selecting a low-cost PLC (Programmable Logic Controller) with HMI (Human-Machine Interface) for industrial automation, striking the right balance between cost-effectiveness and performance is crucial. Many businesses are often tempted to prioritize the lowest price, overlooking the performance capabilities that can significantly impact operational efficiency. A cost-effective solution shouldn't sacrifice essential features such as processing speed, I/O capacity, and scalability. Instead, it should provide enough functionality to handle current needs while also allowing for future growth.

Performance, on the other hand, should not lead to unnecessary expenditures. Upgrading to high-performance PLCs can come with significant costs, and if those features are underutilized, organizations may find their return on investment lacking. To avoid this pitfall, it’s essential to clearly define automation requirements and assess potential projects thoroughly. By evaluating factors such as system complexity, required response times, and the integration of additional equipment, businesses can better align their choices with both their budget and performance needs. The goal is to choose a PLC and HMI solution that provides the best value, achieving an effective balance that supports operational efficiency without overspending.