In the rapidly evolving landscape of industrial automation, the adoption of Distributed Control Systems (DCS) has emerged as a cornerstone for enhancing operational efficiency and reliability. According to a report by MarketsandMarkets, the global DCS market is expected to grow from USD 18.7 billion in 2020 to USD 27.6 billion by 2025, representing a robust CAGR of 8.1%. This growth underscores a significant shift towards decentralized control architectures that offer improved scalability and flexibility. As industries seek to optimize production processes, reduce downtime, and ensure compliance with stringent regulations, DCS provides critical insights and data analytics capabilities. The integration of advanced technologies such as IoT and AI with DCS further amplifies these advantages, making it essential for organizations to embrace these solutions to stay competitive in the evolving market.

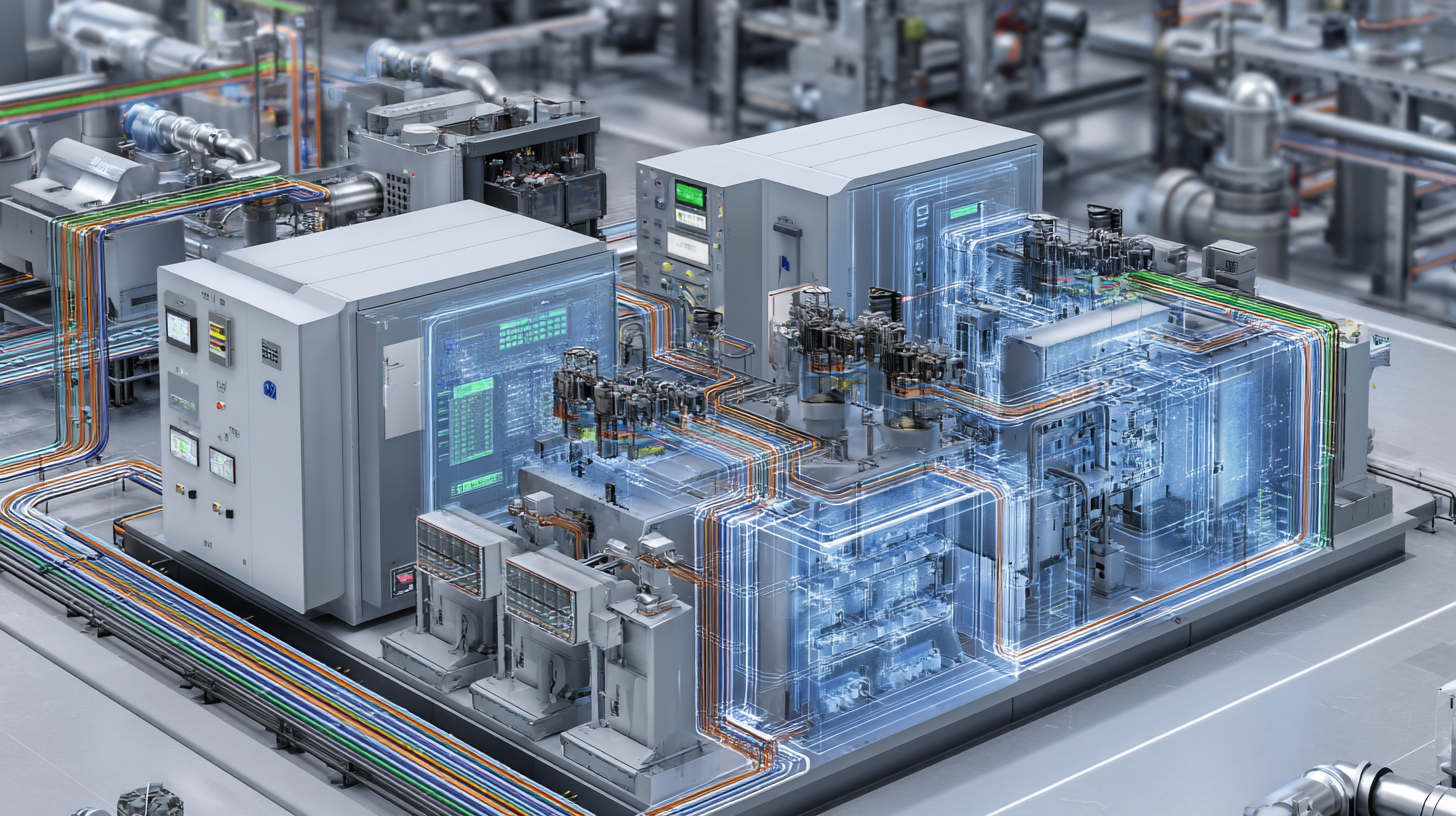

Distributed Control Systems (DCS) have emerged as a pivotal technology in industrial automation, enabling organizations to leverage enhanced productivity across various sectors. By decentralizing control mechanisms, DCS allows for more localized decision-making, which reduces latency and improves response times. This localized approach not only streamlines operations but also increases the efficiency of resource utilization, allowing companies to optimize their workflows and minimize downtime.

Distributed Control Systems (DCS) have emerged as a pivotal technology in industrial automation, enabling organizations to leverage enhanced productivity across various sectors. By decentralizing control mechanisms, DCS allows for more localized decision-making, which reduces latency and improves response times. This localized approach not only streamlines operations but also increases the efficiency of resource utilization, allowing companies to optimize their workflows and minimize downtime.

Moreover, the integration of advanced data analytics within DCS frameworks empowers organizations to gain deeper insights into their processes. With real-time monitoring and predictive analytics, companies can identify bottlenecks and inefficiencies, leading to informed decisions that drive continuous improvement. As industries increasingly adopt smart technologies, the ability of DCS to facilitate seamless communication between devices and systems enhances overall operational visibility. This interconnectedness fosters a culture of agility and flexibility, ultimately resulting in a more productive work environment that can adapt to changing demands swiftly.

The industrial automation market is experiencing significant growth, driven by advancements in technology and an increasing demand for efficiency. Among the key components of this growth are Distributed Control Systems (DCS), which are projected to reach a market size of approximately $34.38 billion by 2032, growing at a compound annual growth rate (CAGR) of 5.58% during the forecast period. This growth is largely attributable to the rising adoption of Industrial 4.0 and smart manufacturing practices that emphasize connectivity and data-driven decision-making.

In addition to DCS, other segments within the industrial automation market are also expanding. The virtual PLC and soft PLC market is expected to reach a valuation of $865 million in 2023, with a forecasted CAGR exceeding 13% from 2024 to 2032. This remarkable growth reflects the shift companies are making towards more flexible and adaptable manufacturing solutions, enhancing operational efficiency, and enabling greater responsiveness to changing market demands. These trends underscore the pivotal role that distributed control systems and advanced automation technologies play in shaping the future of industrial operations.

This bar chart illustrates the percentage increase in efficiency across key industrial sectors utilizing Distributed Control Systems (DCS) from 2020 to 2023.

In the rapidly evolving landscape of industrial automation, implementing distributed control systems (DCS) has become a pivotal strategy for enhancing operational efficiency. Recent industry reports indicate that businesses utilizing DCS can achieve up to a 30% reduction in operational costs, driven by improved process control and real-time data analytics. Best practices for successfully integrating these systems involve a phased approach to ensure both reliability and scalability. Industry experts recommend starting with small pilot projects to test system capabilities before full-scale deployment.

Tip: Prioritize training for your team. Studies show that organizations with comprehensive training programs see a 25% increase in productivity post-implementation. Investing in personnel ensures they can leverage the full potential of DCS technology while minimizing downtime during the transition phase.

Additionally, continuous monitoring and regular updates are crucial for sustaining system performance. According to a recent survey by the International Society of Automation, 67% of companies reported that proactive maintenance significantly lowered equipment failure rates. Engaging with stakeholders during the implementation process can also facilitate smoother integration and align the DCS with overall business objectives.

Tip: Establish a feedback loop among operators and IT staff to identify pain points early and adapt the system accordingly. This iterative approach not only enhances user satisfaction but also drives continuous improvement in operational processes.

The deployment of distributed control systems (DCS) in industrial automation presents significant challenges that organizations must navigate to realize the full benefits of this technology. One of the primary obstacles is the complexity of integrating DCS with existing infrastructure. Many facilities utilize a patchwork of legacy systems that can be incompatible with modern DCS architectures, leading to potential disruptions in operations and increased costs. Ensuring seamless communication between disparate systems requires careful planning and skilled personnel who understand both the old and new technologies.

Another critical challenge lies in the training and adaptation of personnel to effectively use DCS. As operations become increasingly automated, workers need to be equipped with the necessary skills to manage and troubleshoot these advanced systems. This demands not only technical training but also a cultural shift within the organization towards embracing automation. Resistance to change can hinder the successful implementation of DCS, underscoring the importance of comprehensive change management strategies to foster acceptance and engagement among employees. By addressing these challenges proactively, companies can unlock the full potential of distributed control systems and enhance their operational efficiency.

The evolving role of Distributed Control Systems (DCS) in industrial automation is transforming the landscape of manufacturing and process industries. According to a report by MarketsandMarkets, the DCS market is projected to grow from USD 18.97 billion in 2020 to USD 26.21 billion by 2025, at a CAGR of 6.7%. This substantial growth is driven by the increasing adoption of automation technologies aimed at improving operational efficiency and reducing downtime. DCS enables operators to monitor and control processes remotely, harnessing real-time data analytics that enhances decision-making and streamlines production.

Moreover, the integration of IoT and AI technologies into DCS is reshaping its future capabilities. A report from Grand View Research indicates that the global IoT in manufacturing market size is expected to reach USD 531.3 billion by 2025, emphasizing the significance of interconnected systems. As industries adopt more intelligent automation strategies, DCS will play an integral role in facilitating seamless data exchange between machines, providing insights that lead to proactive maintenance and optimized resource utilization. This evolution positions DCS not only as a control mechanism but also as a crucial player in driving digital transformation within industrial environments.