In today's rapidly evolving industrial landscape, the adoption of PLC automation systems has become a cornerstone for enhancing operational efficiency. According to a recent report by MarketsandMarkets, the global PLC market is projected to reach USD 14.8 billion by 2025, growing at a CAGR of 6.9% from 2020. This surge is largely driven by the increasing demand for automation in manufacturing processes and the integration of Industry 4.0 technologies. As companies strive to optimize production workflows and minimize downtime, implementing a comprehensive checklist for PLC automation becomes crucial. Such strategies not only streamline processes but also leverage real-time data analytics, leading to improved decision-making and productivity. By focusing on best practices and key considerations, manufacturers can significantly enhance their operational performance, reduce costs, and foster sustainable growth through PLC automation.

The global industrial automation market is poised for significant growth, with projections indicating a market size of approximately $134.6 billion in 2024, expected to reach around $403.08 billion by 2033. This growth, driven by a compound annual growth rate (CAGR) of 8.5%, highlights the increasing demand for efficiency through advanced automation solutions, particularly programmable logic controllers (PLCs). Understanding the core functions of PLC systems allows businesses to streamline their operations, ultimately enhancing productivity and reducing costs.

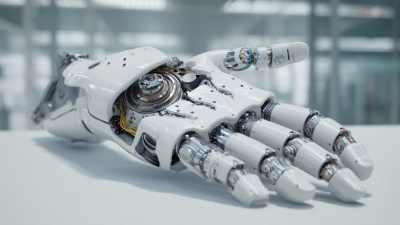

As industries transition from conventional manufacturing to smart manufacturing, the integration of digital automation solutions is becoming paramount. For instance, recent studies reveal that automating processes can lead to substantial improvements in operational efficiency and product quality. With the rise of Robotic Process Automation (RPA) and the Internet of Things (IoT), companies can achieve unprecedented levels of operational sophistication, maximizing asset utilization while minimizing waste.

As manufacturers harness these technologies, they are equipped to navigate the complexities of the global supply chain, positioning themselves for success in an increasingly competitive landscape.

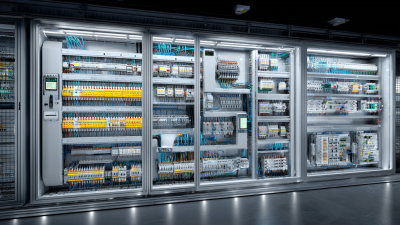

Programmable Logic Controllers (PLCs) have become integral in modern automation systems, significantly enhancing operational efficiency across various industries. One of the key features that drive productivity is their real-time processing capability. PLCs can quickly process large amounts of data and convert it into actionable insights, allowing businesses to monitor processes and make immediate adjustments. This responsiveness minimizes downtime and optimizes production flow, ensuring that operations continue smoothly.

Another critical feature of PLC systems is their ability to integrate seamlessly with other machinery and communication protocols. This interoperability allows for centralized control over multiple processes, simplifying complex operations. Furthermore, the adaptability of PLCs means they can be easily reprogrammed to accommodate changing production requirements or new technologies, providing businesses with the flexibility needed to stay competitive. By harnessing these features, companies can reduce operational costs, enhance safety, and ultimately drive greater productivity in their manufacturing processes.

The integration of IoT with PLC (Programmable Logic Controller) systems is transforming the landscape of automation, enabling smarter and more efficient operations across various industries. According to a report by MarketsandMarkets, the global IoT in manufacturing market is projected to grow from $20.2 billion in 2020 to $56.3 billion by 2025, primarily driven by the demand for real-time data analytics and improved operational efficiency. By combining PLC systems with IoT technology, manufacturers can achieve significant advantages such as predictive maintenance, reduced downtime, and enhanced decision-making capabilities.

One of the key benefits of this integration is the ability to collect and analyze data from machines in real time. A study by McKinsey & Company indicates that predictive maintenance can reduce overall equipment maintenance costs by 10 to 40%, while also decreasing the likelihood of unexpected breakdowns. IoT-enabled PLC systems can monitor equipment health and performance, sending alerts to operators when anomalies are detected, thereby optimizing operational efficiency. As industries adopt these smart automation solutions, they are not only improving productivity but also driving innovation and sustainability in their operations, paving the way for a more connected and responsive manufacturing environment.

In the realm of industrial automation, PLC (Programmable Logic Controller) systems have become the backbone of enhancing operational efficiency. Real-world case studies reveal that manufacturers leveraging PLC automation can achieve a productivity increase of up to 30%, as highlighted in the 2022 report by the International Society of Automation (ISA). Companies in sectors like automotive and food processing are using PLC systems to streamline their production lines, minimize downtime, and ensure consistent product quality.

In the realm of industrial automation, PLC (Programmable Logic Controller) systems have become the backbone of enhancing operational efficiency. Real-world case studies reveal that manufacturers leveraging PLC automation can achieve a productivity increase of up to 30%, as highlighted in the 2022 report by the International Society of Automation (ISA). Companies in sectors like automotive and food processing are using PLC systems to streamline their production lines, minimize downtime, and ensure consistent product quality.

A notable success story involves a leading automotive manufacturer that integrated PLC automation into their assembly processes. The implementation resulted in a remarkable reduction of cycle times by 25%, translating into significant cost savings and improved throughput. Furthermore, reports indicate that factories adopting PLC solutions are experiencing about 20% fewer errors in production, showcasing the technology’s capability to enhance accuracy and reduce waste.

Tip: When considering PLC automation for your business, start with a comprehensive analysis of your current processes to identify specific areas for improvement.

Another effective strategy is to invest in training for your employees on PLC systems, which can help ensure a smooth transition and maximize the benefits of automation. The same ISA report found that businesses with well-trained staff see a 15% improvement in overall efficiency post-implementation. This emphasis on education not only empowers your workforce but also optimizes the return on your automation investment.

The future of PLC (Programmable Logic Controller) automation systems is set to revolutionize efficiency in various industries, driven by advancements in technology and the increasing demand for smart manufacturing. One prominent trend is the integration of IoT (Internet of Things) capabilities, which allows PLCs to communicate with a network of devices, gathering real-time data for analysis. This connectivity not only enhances monitoring and control but enables predictive maintenance, minimizing downtime and maximizing productivity.

Another significant trend is the rise of artificial intelligence and machine learning in PLC systems. These technologies allow for smarter decision-making processes, enabling automation systems to adapt to changing conditions in real-time. By analyzing historical data, AI can optimize operations by predicting potential failures and adjusting operational parameters accordingly. This level of sophistication leads to improved efficiency, reduced operational costs, and enhanced overall performance for manufacturing processes.

As industries continue to adopt these cutting-edge technologies, we can expect PLC automation systems to undergo significant transformations. The impact on efficiency will be profound as organizations leverage these advancements to streamline operations, improve resource utilization, and stay competitive in an increasingly dynamic market. Embracing these trends will not only enhance operational efficiency but also pave the way for a more sustainable and resilient future in automation.