Choosing the right Automation Parts can significantly impact your business efficiency. John Smith, a leading expert in automation technology, states, "The right components can make or break your workflow." Understanding the diverse options available is essential for making informed decisions.

Automation parts include sensors, controllers, and actuators. Each has its unique role, affecting overall performance. It's crucial to analyze your specific needs and objectives. However, navigating the options can be overwhelming. Many businesses often end up with components that do not fully meet their requirements. This can lead to inefficiencies and lost productivity.

Taking the time to assess your applications is vital. Speak with professionals, and gather insights. Not all parts suit every operation. Knowing when to invest and when to prioritize repairs is equally important. A thoughtful approach ensures that your automation strategy works seamlessly with your business goals.

Identifying your business automation needs is crucial for success. Understanding the specific processes you want to automate is a good starting point. A recent report noted that 61% of businesses have fully automated at least one task. This reflects a growing trend. However, companies must avoid common pitfalls, such as automating without a defined purpose.

Assessing your objectives helps determine the right tools for automation. Focus on areas that will provide the most efficiency. According to industry surveys, 43% of organizations still struggle with poorly defined automation goals. This lack of clarity often leads to wasted resources and time. Business leaders should prioritize aligning automation solutions with their strategic goals.

Thanks to evolving technologies, there is a myriad of automation options available. Yet, it’s important to evaluate risks and benefits before committing. Many automation projects fail due to unrealistic expectations. Companies must consider their specific needs carefully. Identifying your business's unique challenges will pave the way for effective automation deployment.

When evaluating automation parts for your business, it’s crucial to consider different types available in the market. These parts vary widely, from sensors to actuators and controllers. Understanding their functions can help you make informed decisions. For example, sensors detect changes in the environment, such as temperature or pressure. This data plays a vital role in automating processes effectively.

Actuators, on the other hand, convert energy into motion. They are essential for executing the commands received from controllers. It's worth noting that not all actuators suit every application. Some may underperform in specific setups, leading to inefficiencies. Controllers manage the entire automation system. Their capability of processing data determines how well your automation functions.

It’s essential to assess compatibility with existing systems. Sometimes, a part seems perfect but fails to integrate seamlessly. Testing different components in real-world scenarios can reveal hidden challenges. Additionally, analyzing long-term reliability is vital. A part that works well initially may have a short lifecycle. Reflecting on these aspects ensures you choose the best automation parts for your unique needs.

When selecting automation parts for your business, compatibility with existing systems is crucial. Check the specifications of current equipment. Outdated systems may not support newer technology. Conduct thorough assessments to avoid potential integration issues. Take special care with legacy systems, as they often present unique challenges.

Tips: Start with a compatibility checklist. Identify elements that must work together. This can save time and resources. Don't overlook software compatibility. Many businesses face challenges due to mismatched software capabilities. Integration can become a nightmare if not properly evaluated.

It's common to assume new parts will easily fit in. However, this is not always the case. Sometimes, modifications are needed. Reflect on previous experiences with integration failures. Assess past mistakes to improve future choices. Remember, the goal is seamless operation and enhanced efficiency. Don’t rush this vital step. Careful planning pays off.

| Part Type | Compatibility Rating | Integration Ease | Cost Estimate ($) | Recommended Use Case |

|---|---|---|---|---|

| Sensor | High | Easy | 150 | Monitoring environmental conditions |

| Controller | Medium | Moderate | 300 | Managing automated tasks |

| Actuator | High | Difficult | 250 | Controlling physical devices |

| Software Interface | Medium | Easy | 200 | Data analysis and visualization |

| Power Supply | High | Easy | 120 | Powering automation systems |

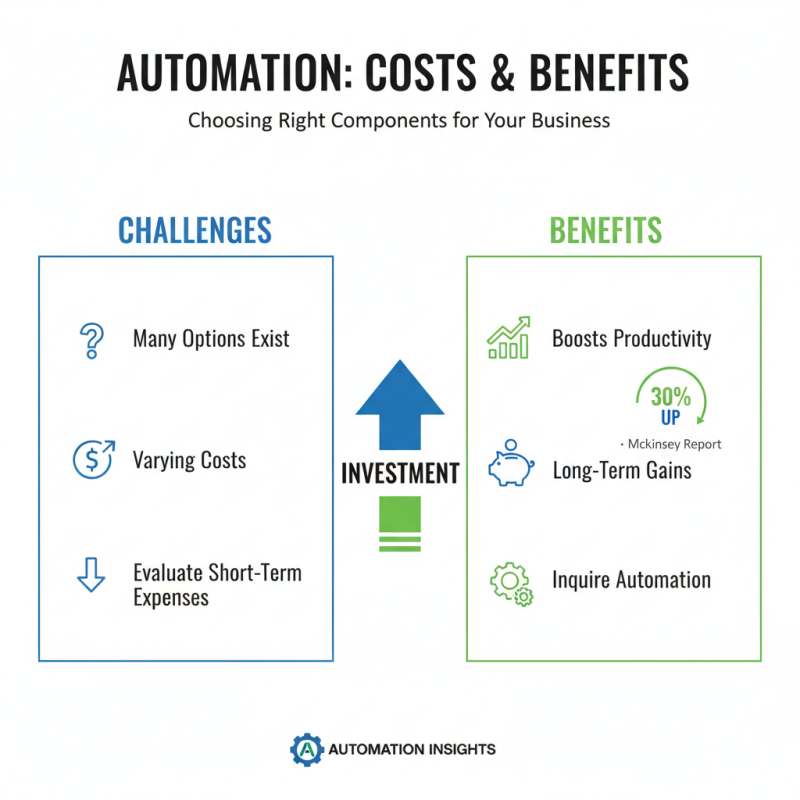

Choosing the right automation components for your business can be challenging. Many options exist, each with its own costs and benefits. A recent report by McKinsey suggests that investing in automation can boost productivity by up to 30%. However, companies must evaluate both short-term expenses and long-term gains.

When comparing costs, consider the initial investment versus ongoing maintenance. For instance, robotic process automation (RPA) can require substantial upfront costs. Yet, it may lead to savings of 20-30% in operational expenses. Your team may face resistance to change. Sometimes, those emotions can inhibit efficiency. Training investments can bridge this gap.

**Tips**: Analyze your current workflows. Identify areas ripe for automation. Estimate the return on investment carefully. It's also wise to start small. Pilot projects can mitigate risks and help refine strategies. Watch for hidden costs that may arise post-implementation. Consistent evaluation is key to maximizing benefits.

Every business is unique. Some solutions may excel in one scenario but falter in another. Understand your specific needs, and be cautious about overestimating potential. Balancing costs with realistic benefits requires ongoing assessment and adaptation.

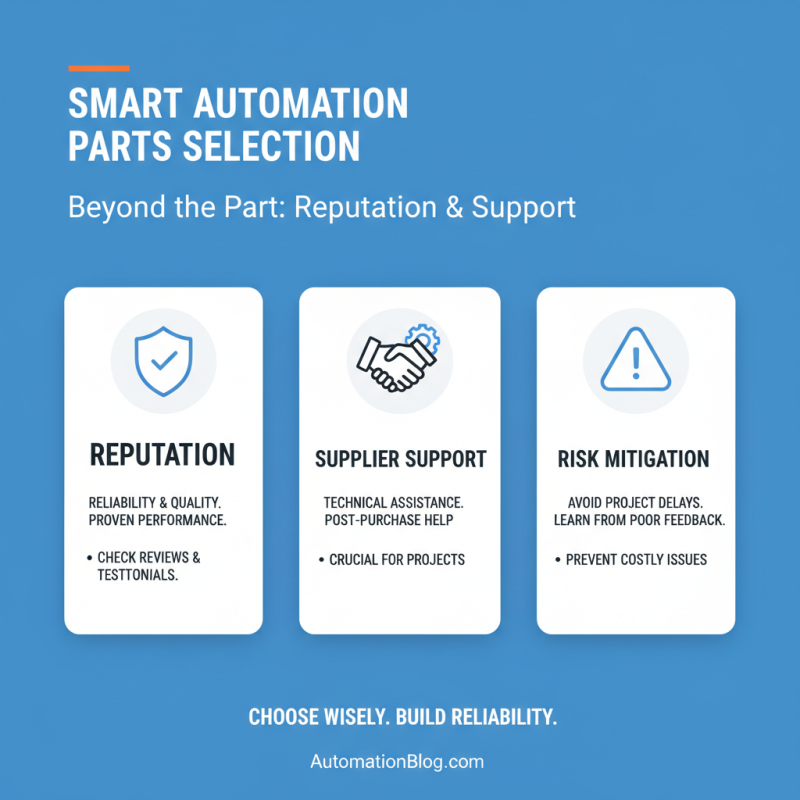

When selecting automation parts, supplier reputation and support services are crucial. A strong reputation indicates reliability and quality. Look for reviews and testimonials from past customers. These can provide insights into the supplier's performance. Poor feedback often highlights issues that can affect your projects.

Support services are equally important. Will the supplier be available when problems arise? Quick assistance can minimize downtime. Investigate their customer service options. Do they offer technical support, training, or maintenance services? These factors can greatly influence the effectiveness of your automation systems.

Also, consider the supplier’s experience in your specific industry. They should understand your unique needs. A lack of relevant experience might lead to mismatched parts or inadequate support. Reflect on previous experiences with suppliers. Did they meet your expectations? Addressing past disappointments can help guide your current choices.