In today's rapidly evolving industrial landscape, optimizing performance is paramount for businesses aiming to maintain a competitive edge. Recent reports indicate that effective automation solutions can enhance operational efficiency by up to 30% while significantly reducing downtime (Source: McKinsey & Company, 2022). Among the leading solutions in the market, Schneider PLC stands out due to its reliability, scalability, and advanced technological features. With its ability to integrate seamlessly into diverse operational environments, Schneider PLC not only supports real-time monitoring and control but also promotes data-driven decision-making. This blog will explore ten strategies to maximize performance using Schneider PLC, helping industrial operators harness the full potential of their automation systems and respond agilely to the demands of the industry.

Identifying your industrial automation goals is crucial for optimal performance with the best Schneider PLC. According to a recent report by the International Society of Automation, nearly 60% of industrial companies do not fully utilize their automation capabilities due to unclear objectives. This lack of direction often leads to inefficient processes and increased downtime, which can cost manufacturers up to 15% of their annual revenue. Therefore, it's essential to clearly define objectives such as increasing production efficiency, enhancing process control, or reducing energy consumption to leverage the full potential of Schneider PLCs.

A well-defined goal aligns your system's capabilities with business objectives. For instance, if a facility aims to decrease cycle times, selecting a Schneider PLC equipped with advanced features such as real-time data processing and predictive analytics can yield significant improvements. A case study by IndustryWeek revealed that plants employing smart automation technologies, including Schneider PLCs, saw a 20% reduction in operational costs within the first year of implementation. This highlights the importance of setting precise industrial automation goals to guide technology choices, ensuring the selected PLC meets specific performance criteria and supports sustained operational excellence.

When selecting the right Schneider PLC model for specific industrial applications, it's crucial to consider the unique requirements of each operation. Different industries have varying demands for speed, control complexity, and integration capabilities. Tip: Conduct a thorough assessment of your operational needs alongside your future expansion plans to ensure you choose a PLC that can grow with your business.

Another essential aspect is understanding the environmental conditions of your application site. Factors like temperature, humidity, and potential exposure to contaminants can influence the choice of PLC model. Tip: Opt for a PLC with suitable ingress protection (IP) ratings and temperature tolerances to ensure reliability and longevity in your specific environment.

Lastly, consider the ease of programming and integration with existing systems. A user-friendly interface can significantly reduce training time and operational disruptions. Tip: Look for models that support popular programming languages and offer seamless integration options with your current hardware and software systems to maximize performance and efficiency.

| Application Area | Recommended PLC Model | Key Features | Performance Metrics | Scalability Options |

|---|---|---|---|---|

| Manufacturing Automation | Model A | Fast processing, multiple I/O support | 1000 operations/sec | Expandable I/O modules |

| Process Control | Model B | Integrated PID control, high reliability | 2000 operations/sec | Up to 128 I/O points |

| Building Automation | Model C | Energy-efficient, remote management | 500 operations/sec | Cloud integration capability |

| Food and Beverage | Model D | Hygienic design, process tracking | 1500 operations/sec | Modular expansion options |

| Water Treatment | Model E | Robust performance, real-time data | 3000 operations/sec | Flexible I/O configurations |

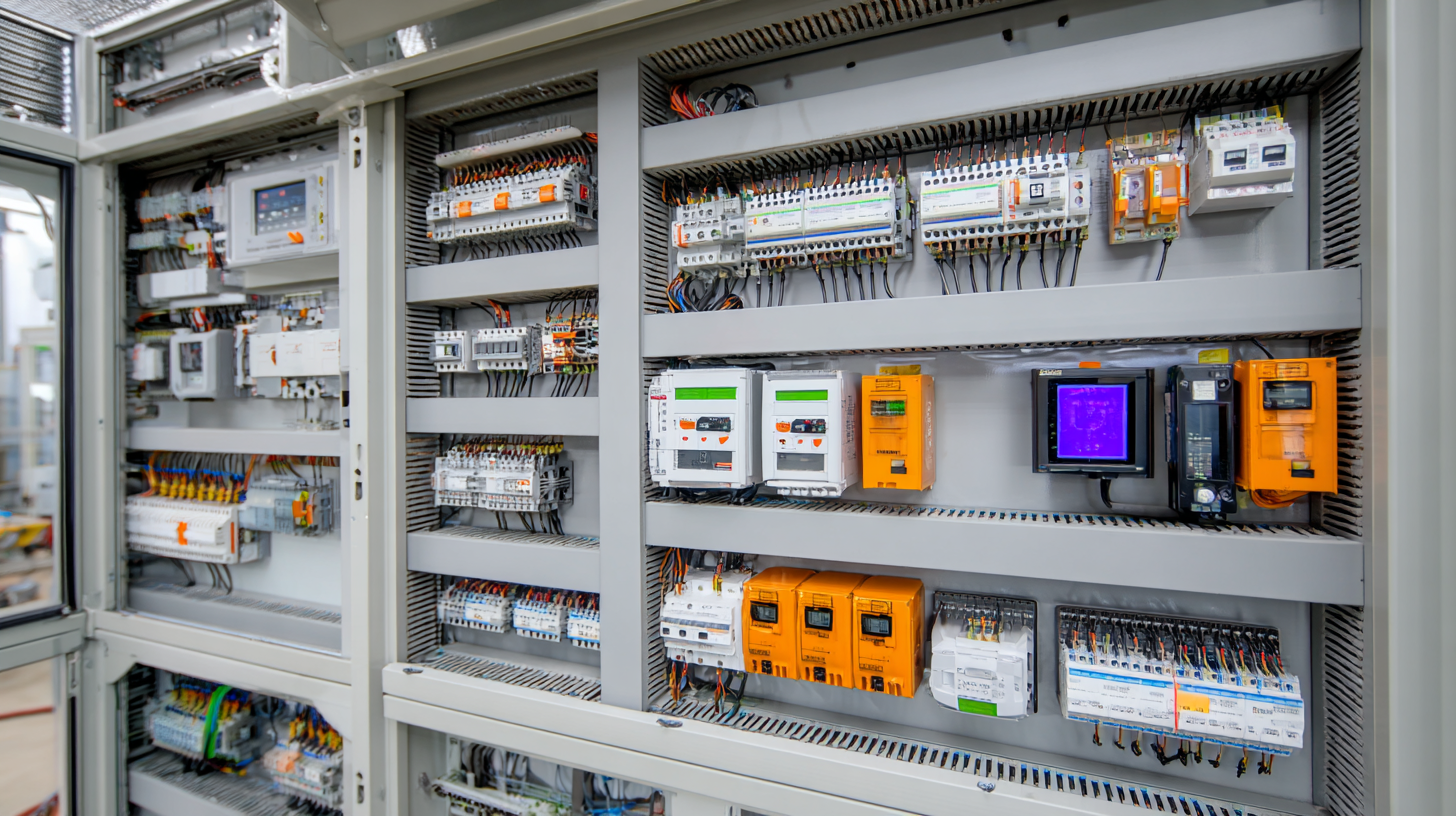

Integrating Schneider PLCs with existing systems is pivotal for enhancing efficiency in industrial operations. The adaptability of Schneider PLCs allows them to seamlessly connect with various legacy systems, facilitating smoother transitions and minimizing disruptions. This integration is not only about connecting new technology with old; it also involves optimizing data flow and communication among different machinery. By employing standard communication protocols and customizable interfaces, businesses can leverage their existing infrastructures while harnessing the advanced capabilities of Schneider PLCs.

Moreover, integrating Schneider PLCs can lead to significant improvements in process monitoring and control. The real-time data analytics provided by these programmable logic controllers enable manufacturers to make informed decisions swiftly. By bridging the gap between old and new, organizations can enhance their overall operational efficiency, reduce downtime, and significantly lower costs. With proper integration strategies, industries can ensure that their systems perform at peak efficiency, thus maximizing their return on investment in Schneider technology.

When implementing best practices in programming for Schneider PLCs, it is essential to adhere to industry standards and guidelines to maximize functionality. According to a recent report by MarketsandMarkets, the global PLC market is expected to grow from $84.9 billion in 2022 to $116.9 billion by 2027, emphasizing the increasing reliance on PLCs in various industrial applications. This surge in demand underscores the critical need for optimized programming techniques that not only improve operational efficiency but also enhance system reliability.

One of the best practices includes utilizing structured programming methods such as Function Block Diagrams (FBD) and Ladder Logic (LD), which can significantly reduce programming errors and simplify maintenance. A study by ARC Advisory Group noted that companies that implemented standardized programming practices reported up to a 30% reduction in debugging time and an increase in overall equipment effectiveness (OEE) by 20%. Furthermore, developing modular code that allows for reusable components can streamline the programming process, facilitating quicker adjustments and upgrades in response to evolving operational demands. Implementing these best practices ensures that organizations fully leverage the capabilities of Schneider PLCs, ultimately leading to improved productivity and reduced downtime.

When it comes to maximizing the performance of Schneider PLCs in industrial settings, monitoring and maintenance strategies play a crucial role. Regular monitoring of PLC systems allows operators to identify potential issues before they escalate into major problems. Implementing real-time data analysis tools can provide insights into system health and performance metrics, enabling teams to make informed decisions. Additionally, embracing predictive maintenance techniques can significantly reduce unexpected downtime, allowing for smoother operations and enhanced productivity.

Another effective strategy is to establish a routine maintenance schedule. Consistent inspection and servicing of the PLC hardware and software not only prolong the lifespan of the equipment but also ensures optimal performance. Technicians should focus on updating firmware, checking connections, and cleaning components, as small oversights can lead to significant disruptions. Furthermore, keeping a detailed log of maintenance activities helps in tracking performance trends and making future adjustments more feasible, ultimately leading to improved efficiency in industrial processes.