In the realm of industrial automation, optimizing your DCS Control System is crucial for enhancing performance. John Smith, a leading expert in control systems, once stated, "A well-tuned DCS can significantly reduce operational costs." This perspective emphasizes the importance of fine-tuning your control system.

Every facility relies on its DCS for efficiency. However, many systems remain underutilized. Poor configurations or outdated hardware can hinder performance. Without regular updates, your DCS may fall short of its potential.

Investing in training for your team can transform your DCS Control System. Hands-on experience can highlight gaps in performance. Addressing these issues requires careful evaluation and may lead to unexpected revelations. The journey towards optimization is filled with challenges, but the benefits are undeniable. Your DCS could be the key to unlocking greater operational success.

Distributed Control Systems (DCS) play a crucial role in modern industrial settings. These systems help manage complex processes across various sectors like manufacturing and energy. Understanding DCS fundamentals is essential for anyone looking to improve system performance. At their core, DCS consists of sensors, controllers, and actuators that work together seamlessly.

One key aspect is the importance of effective communication between components. Data sharing should be fast and reliable. If communication lags, decision-making suffers. Additionally, user interfaces must be intuitive, allowing operators to respond quickly to issues. Operators should be trained to interpret information efficiently. Misunderstandings can lead to severe consequences.

Another area to consider is maintenance. Routine checks are vital. Neglecting this can cause unexpected downtimes. It’s easy to overlook minor malfunctions until they escalate. This can result in significant operational delays. Regular system evaluations can uncover hidden inefficiencies that require attention. Careful monitoring can prevent larger problems down the line.

In optimizing your DCS control system, identifying key performance indicators (KPIs) is essential for achieving better performance. KPIs like system uptime, response time, and efficiency metrics are crucial. Industry reports indicate that systems with well-defined KPIs can improve operational efficiency by over 30%. This enhancement leads to significant cost savings, making the investment worthwhile.

Tips: Regularly review your KPIs. Adjust them based on system performance and operational goals. This small change can yield great insights.

Another important KPI is the alarm management system's effectiveness. Poor alarm management can lead to operator fatigue and missed critical events. Research shows that organizations with optimized alarms reduce unnecessary alarm rates by around 40%. This can make a considerable difference in real-time decision-making.

Tips: Use the 80/20 rule for alarms. Focus on the 20% of alarms that cause 80% of issues. This will help prioritize your improvements.

Considering system response times is also critical. Delays in response can lead to inefficiencies. According to a study, every second of delay can decrease productivity by 1.5%. Reflect on your current response times regularly and seek ways to shorten them.

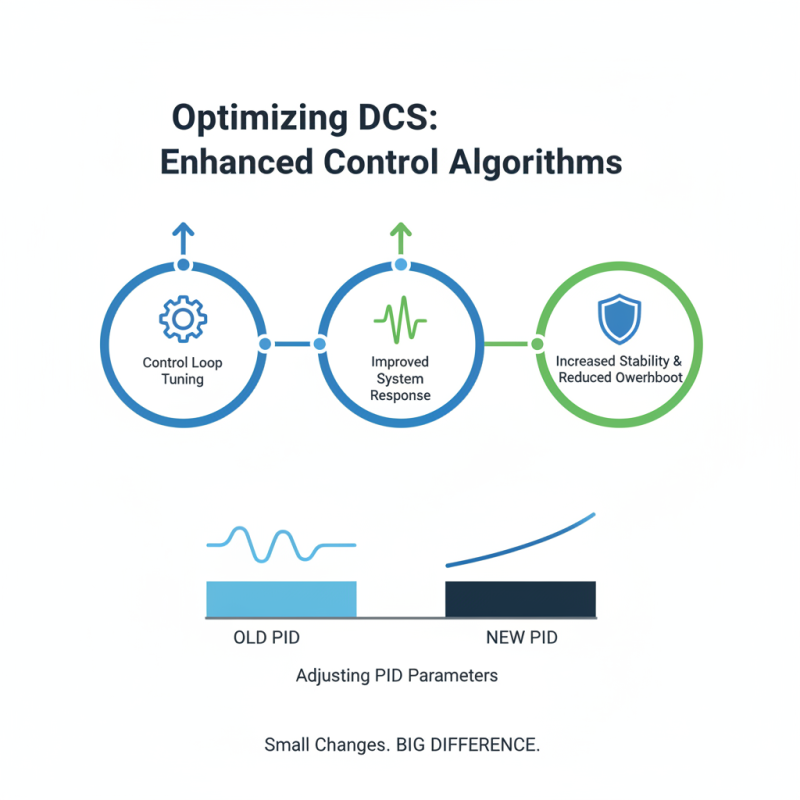

In optimizing your Distributed Control System (DCS), enhancing control algorithms plays a vital role. One effective technique is employing better control loop tuning. This can significantly improve system response times. Adjusting PID parameters can lead to increased stability and reduced overshoot. Small changes can make a big difference.

Tips: Regularly review control loop performance. Identify underperforming loops and make adjustments. Continuous monitoring can prevent system degradation.

Another useful approach is implementing advanced control strategies, such as model predictive control. This technique uses models of the process to anticipate future behavior. It helps in making proactive adjustments, enhancing overall performance. However, it requires accurate models, which can be a challenge. If your model is not precise, the control may react inaccurately.

Tips: Start small when integrating new strategies. Test in a controlled environment before full implementation. Incremental changes can minimize risks.

Lastly, data analytics can reveal patterns that traditional methods might miss. Analyzing historical data can uncover inefficiencies in your control algorithms. Yet, this requires careful interpretation. Misunderstanding data can lead to suboptimal decisions.

Tips: Use visualization tools to simplify data interpretation. Collaborate with team members to gain different perspectives.

Advanced data analytics stands as a cornerstone for optimizing Distributed Control Systems (DCS). By harnessing real-time data, facilities can identify inefficiencies. According to recent studies, organizations that implemented data analytics reported a 20% increase in operational efficiency. This transformation stems from predictive maintenance and enhanced process control.

The integration of machine learning algorithms can unveil hidden patterns in process data. Some facilities have reduced downtime by 15% through predictive insights. However, many struggle with data silos, limiting the insights they can gain. A report highlighted that 40% of data generated goes unanalyzed. This gap poses significant risks to performance optimization.

Moreover, ensuring data quality is another challenge. Inaccurate data can lead to misguided decisions. Investing in data cleansing tools can be beneficial. Yet, the journey to data-driven excellence is riddled with obstacles. As organizations embrace advanced analytics, reflecting on their current practices is crucial. Real progress hinges on commitment and adaptability.

This chart illustrates the performance metrics of a DCS control system before and after optimization. Significant improvements can be observed in response time, throughput, error rate, and resource utilization, showcasing the benefits of implementing advanced data analytics.

Regular maintenance is crucial for sustaining the efficiency of a Distributed Control System (DCS). Operators should routinely check system components, including sensors and actuators. Neglected sensors can degrade response times. A simple visual inspection can reveal dirt or corrosion. Regularly replacing worn-out parts is essential to prevent unexpected failures.

Calibration is another key practice. Sensors drift over time, impacting system accuracy. Setting a calibration schedule can help catch these problems early. Even minor inaccuracies can lead to significant efficiency losses. Uncalibrated systems can produce inconsistent outputs. This variability can cause operational challenges and trigger alarms that waste resources.

Keeping software updated is equally important. Outdated software can introduce bugs and vulnerabilities. Regular software reviews should be part of the maintenance routine. If some updates are skipped, existing issues may persist. Always document changes and findings during maintenance. This information helps identify recurring issues. Consistent records aid in refining maintenance strategies for better DCS performance.