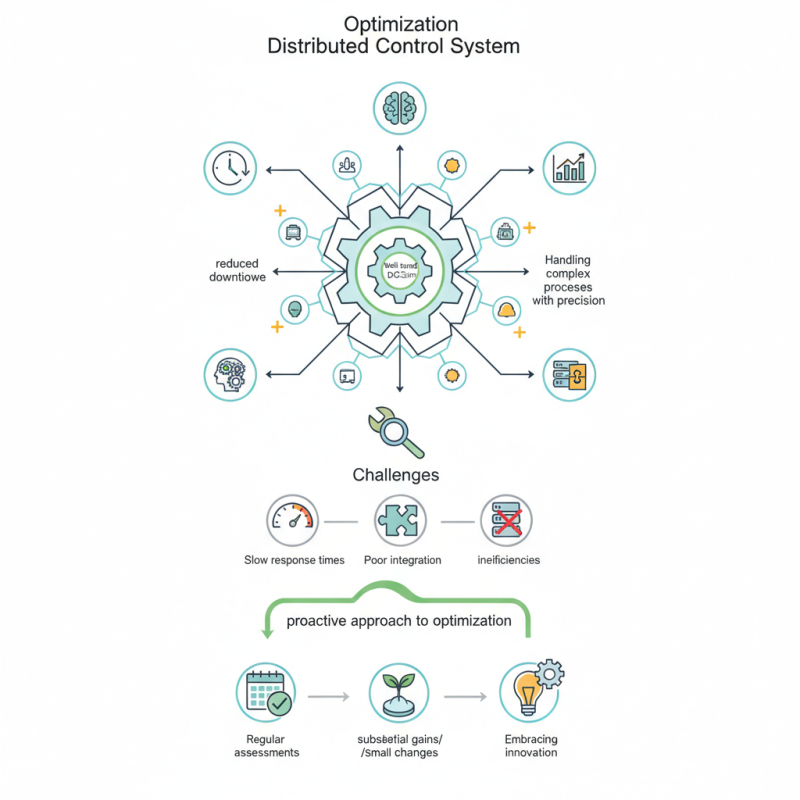

In the realm of industrial automation, optimizing a DCS System is crucial for enhancing performance. Experts like Dr. John Smith, a leading consultant in process automation, emphasize, "A well-tuned DCS System can significantly reduce downtime and improve efficiency." His insights reflect the industry's need for continuous improvement.

The DCS System serves as the backbone for many industries, handling complex processes with precision. However, many facilities still struggle with inefficiencies. Common issues include slow response times and poor integration with new technologies. These challenges highlight the necessity for a proactive approach to optimization.

Understanding the nuances of a DCS System can lead to substantial gains. Regular assessments and adjustments are essential. Facilities should not overlook the potential for improvement. Small changes often yield significant benefits. Embracing innovation while addressing existing flaws can pave the way for enhanced operational outcomes.

Distributed Control Systems (DCS) play an essential role in modern industrial environments. These systems allow for centralized management of complex processes. Each component operates independently but communicates within the network. This ensures efficiency and reliability in various applications.

To optimize a DCS, understanding its architecture is crucial. Controllers, sensors, and actuators must work in harmony. A poorly configured sensor can disrupt the entire workflow. Regularly reviewing each system component is key. This reveals potential weaknesses and areas for improvement. Sometimes, simpler solutions are overlooked. Small adjustments can lead to noticeable gains in performance.

Additionally, training staff on DCS functionalities is vital. Even the most advanced system can falter without knowledgeable operators. Many overlook this aspect. Ensuring that personnel are confident with the technology can prevent critical errors. In transformation, taking feedback from operators might be uncomfortable. However, it's essential for continuous improvement.

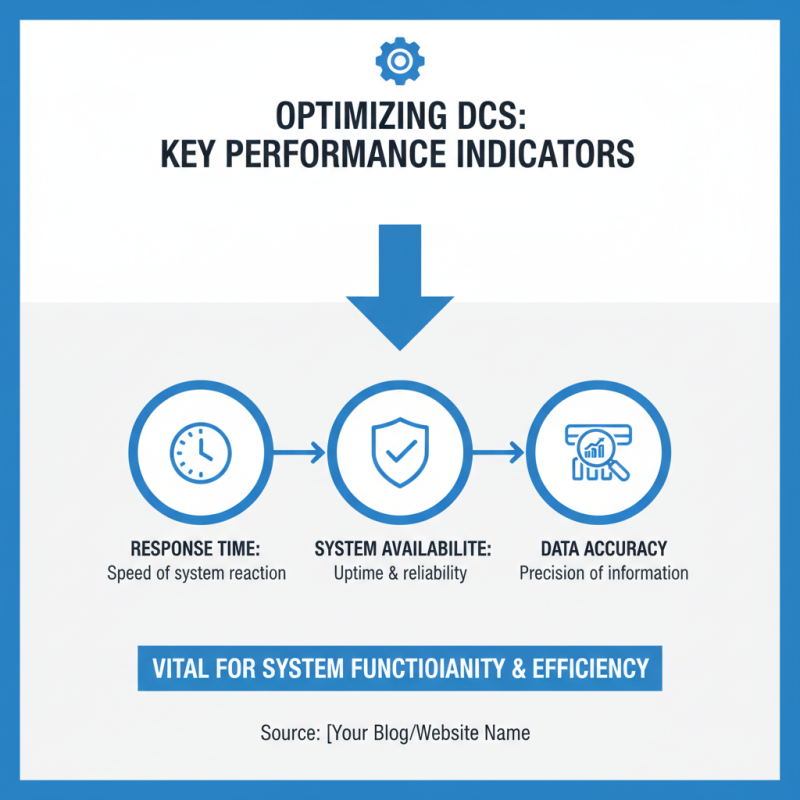

Performance metrics are vital for optimizing distributed control systems (DCS). First, identifying key performance indicators (KPIs) is essential. Some examples include response time, system availability, and data accuracy. Each metric reflects a different aspect of system functionality.

Assessing response time helps understand how quickly the system reacts to commands. An ideal response is crucial in control environments. However, this metric can sometimes overlook latency factors in data transmission. This gap might need attention during optimization efforts.

System availability also plays a pivotal role. It indicates how much time the system is operational and accessible. High availability is desired, but achieving it can be challenging. Regular maintenance schedules might affect accessibility.

Data accuracy is another critical metric. It measures the precision of the data processed by the DCS. Sometimes, discrepancies in data may go unnoticed. Continuous monitoring and validation processes are necessary to ensure data integrity.

Focusing on these metrics leads to a clearer understanding of DCS performance. It can help pinpoint weaknesses, enabling better optimization strategies. Regularly reviewing these metrics fosters a culture of continuous improvement within the system.

Optimizing Distributed Control Systems (DCS) requires systematic software upgrades and patches. Regular updates enhance security and performance. A study by the International Society of Automation revealed that 45% of control system incidents stem from outdated software. Ignoring these upgrades can lead to significant downtime.

Upgrade processes must be meticulous. A poorly implemented patch can create vulnerabilities. In some cases, organizations have faced up to 30% operational inefficiency due to software lag. This is a clear indication that organizations must prioritize timely software maintenance. Patches should not only be applied; they should be tested in a safe environment first.

Integrating automation can streamline this upgrade process. However, it is vital to monitor system performance post-implementation. While some improvements may be immediate, others may require time to surface. Continuous assessment ensures that the upgrades are effective. Regularly engaging with industry benchmarks can help identify areas for improvement. Adapting to these findings can significantly elevate system performance.

| Dimension | Details | Benefit |

|---|---|---|

| Software Version | Version 5.2.1 | Improved security features |

| Patch Level | Critical security patches applied | Reduced vulnerability to attacks |

| System Performance | Increased response time | Enhanced operational efficiency |

| User Training | Regular training sessions | Better utilization of upgraded features |

| Monitoring Tools | Integrated diagnostic tools | Proactive issue resolution |

The performance of a Distributed Control System (DCS) can greatly depend on the

network infrastructure supporting it. A reliable,

high-speed network is crucial. Network latency can slow down response times, leading to inefficiencies.

Regularly assess the network for bottlenecks. Check

for overloaded switches and routers. Evaluate data flow between devices to ensure seamless communication.

Upgrading to fiber optic cables may enhance speed.

These cables offer lower latency compared to traditional copper. Implementing Quality of Service (QoS)

protocols helps prioritize critical data. Not all traffic is equal; sometimes, real-time data gets lost

in the shuffle. Investing in redundant pathways can guard

against failures. This might add complexity, but it prevents downtime.

Monitoring tools provide insights into network performance. It's vital to adjust configurations based on

real-time data. A proactive approach is essential. Review network performance regularly

to identify issues. Sometimes, teams may overlook problems due to complacency. Regular reviews help in

catching these oversights before they impact DCS efficiency.

Regular maintenance and monitoring of Distributed Control Systems (DCS) are crucial for optimizing their performance. According to a recent industry report, ineffective maintenance can increase operational costs by up to 25%. Ensuring that systems are regularly checked helps prevent performance degradation. Common issues, like sensor drift or communication failures, can go unnoticed without proper oversight.

Implementing a routine maintenance schedule can dramatically reduce unplanned downtime. The report suggests that 70% of DCS failures stem from inadequate monitoring. Frequent assessments of system components, such as controllers and network infrastructure, can identify issues early. However, many operators often overlook minor problems, assuming they'll resolve over time. This mindset can lead to significant inefficiencies and costly repairs.

Moreover, continuous training for personnel is often neglected. Often, teams do not stay updated with the latest monitoring technologies. This gap can hinder effective troubleshooting, ultimately affecting productivity. Evaluating performance metrics should be a continuous process, not just a quarterly task. Only then can operators truly understand their system's health and foster an environment for consistent improvement.