Understanding Siemens Plc is pivotal for grasping industrial innovation trends. Siemens Plc is a global leader in technology and engineering. Its influence shapes modern industries, driving change and efficiency. Renowned industry expert Dr. Maria Chen emphasizes, “Siemens Plc transforms industries through innovation and technology adaptation.”

In sectors like manufacturing and energy, Siemens Plc enhances processes with advanced solutions. However, the company faces challenges with rapid technological shifts. These shifts can overwhelm existing systems and require constant adaptation. Siemens Plc must continuously innovate to stay relevant.

Moreover, while Siemens Plc promotes progress, it also raises questions about sustainability and labor displacement. Industries must find balance amidst automation. Siemens Plc's journey exemplifies both potential and pitfalls in innovation, urging stakeholders to reflect on future impacts.

Siemens PLC has a rich history that traces back to the mid-19th century. Founded by a visionary engineer, it began as a telegraph company. Over the decades, it expanded into various sectors like energy, automation, and healthcare. The company embraced innovation, which became central to its identity. Significant contributions shaped industries worldwide, yet it faced challenges along the way.

One illuminating moment was its role in electrical engineering. The invention of the first electric railway marked a transformative period. This breakthrough influenced urban transportation. Another key development was in industrial automation. However, the speed of change sometimes left behind small businesses struggling to adapt. Not all attempts at innovation were successful. Mistakes were made, particularly in new markets. Learning from these missteps has been crucial for growth.

Understanding this historical backdrop shows how deeply intertwined innovation and resilience are. Each advancement is a lesson learned, reminding us that progress involves trial and error. The company has faced criticisms, but these experiences shaped its current strategy. Ultimately, its evolution reflects a broader story of industry innovation over time.

Siemens PLC has been a significant driver of innovation across various industries. Its impact on manufacturing technology is noteworthy. Recent industry reports indicate that over 70% of manufacturers now use automation solutions. These solutions streamline production processes and minimize human error, enhancing overall efficiency. However, not all companies can easily adapt to these technologies, creating a gap in performance.

In the energy sector, Siemens PLC introduced innovative wind turbine designs that increase energy capture efficiency. Studies show that these turbines can boost energy production by up to 20%. But the integration of such technology is not without its challenges. Some regions lack the necessary infrastructure to support these advances. A disparity exists between where innovations are developed and where they can be implemented effectively.

In healthcare, Siemens PLC's diagnostic imaging technology has transformed patient care. The company’s advanced imaging systems have improved diagnostic accuracy, with studies reporting a 30% increase in detection rates for certain conditions. Yet, high costs remain a barrier for many healthcare facilities. Achieving widespread adoption requires addressing financial constraints while ensuring the technology's benefits are accessible to all.

The impact of Siemens PLC on global industrial practices is significant. This company plays a crucial role in shaping modern manufacturing standards. It embraces various technologies that drive efficiency and innovation.

Digitalization is one of the core areas where it influences practices. Smart factories are becoming more common, thanks to these advancements.

However, not all transitions are seamless. Some companies struggle to adapt to new technologies. The gap in skills can hinder implementation. A sudden shift can overwhelm traditional systems.

There is often a fixation on the newest tech, potentially neglecting existing operational strengths.

Additionally, sustainability practices are becoming a focal point. Industries are under pressure to reduce their carbon footprint. This challenge requires innovative solutions, which Siemens PLC addresses.

Yet, the path to these solutions is filled with complexities. Organizations must balance profitability with environmental responsibility. Such contradictions invite ongoing reflection and adaptation.

Digital transformation in industries is rapidly changing how businesses operate. Many organizations are focusing on integrating automation and data analytics to enhance efficiency. Reports indicate that industries adopting digital technologies can increase productivity by up to 30%. However, this shift is not without challenges.

There is a significant skills gap in the workforce. Furthermore, many companies struggle with implementing new technologies due to outdated infrastructure. Data shows that over 70% of organizations face obstacles during digital transformation. They often lack the necessary resources or strategy. While the potential for innovation is immense, the risks of failing to adapt are substantial. Companies must critically assess their readiness and the impact of such changes.

The future landscape promises more intelligent systems and interconnected devices. Predictive maintenance can reduce downtime by up to 20%. Nevertheless, organizations should remain cautious. Investments in new technology don't always yield instant results. Continuous evaluation and adaptation are vital to successfully navigate this evolving landscape. Embracing digital transformation is essential, but it requires thoughtful strategies and realistic expectations.

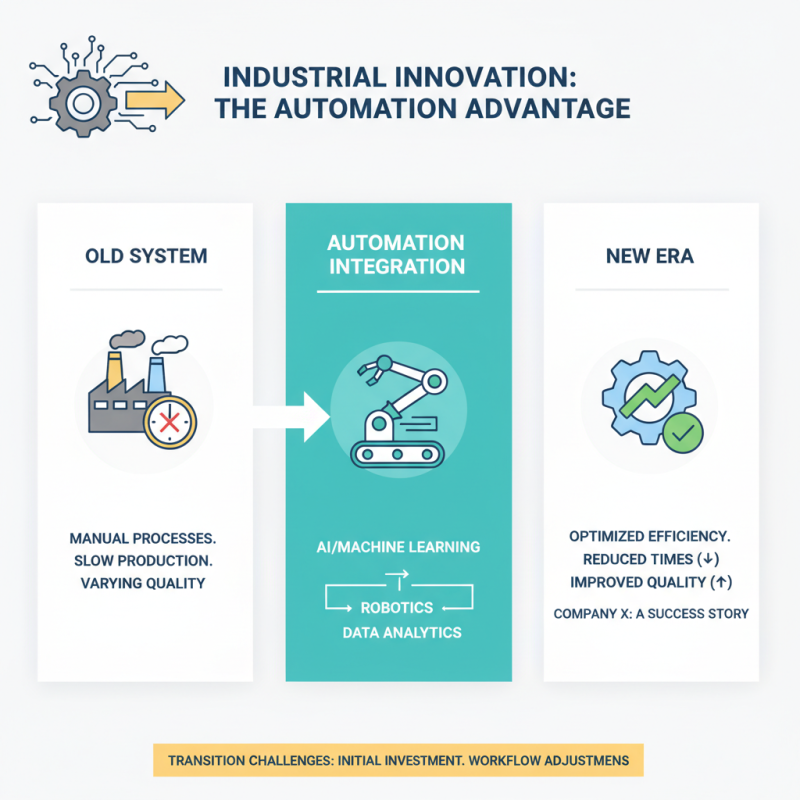

In the realm of industrial innovation, understanding systems that drive efficiency is vital. One company has made significant strides in this area. By implementing automation technologies, it changes how industries operate. These advancements enable companies to reduce production times and improve quality. However, the transition is not always seamless.

A case study from the manufacturing sector illustrates both the potential and challenges. An organization adopted advanced automation solutions. Initially, they faced resistance from employees. Workers worried about job security. Yet, over time, training programs helped ease these concerns, demonstrating the importance of communication. Despite the hurdles, production rates increased remarkably, showcasing innovation’s potential impact.

Another interesting example emerges in transportation. A project integrating smart technologies aimed to optimize logistics. Initial setbacks included compatibility issues with existing systems. These problems delayed deployment and led to frustration. Nonetheless, the long-term benefits were undeniable. Efficiency improved, delivery times shortened, and costs reduced. This highlights innovation's dual facets: its promise and the ongoing need for careful implementation.