In modern engineering, control systems play a pivotal role. Dr. Emily Chen, a leading expert in automation, once stated, "Control systems are the backbone of intelligent technology." This assertion highlights the critical nature of these systems. They enable precise manipulation of processes across various industries. From aerospace to manufacturing, control systems ensure efficiency and safety.

These systems can range from simple feedback loops to complex algorithms. They manage everything from temperature control in HVAC systems to autopilot in aircraft. Yet, not every implementation is flawless. Engineers often face challenges in designing systems that are both robust and adaptable. Real-world variables can lead to unexpected outcomes.

The landscape of control systems is constantly evolving. Emerging technologies like artificial intelligence bring new possibilities but also new complexities. As industries adapt, the need for innovative control systems increases. It invites engineers to reflect on current methods and improve upon them. This duality of opportunity and challenge defines the ever-present need for excellence in control systems.

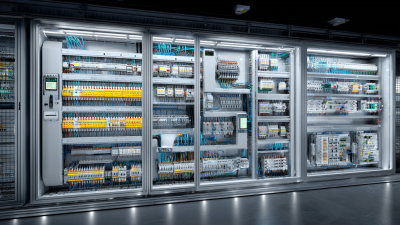

Control systems play a vital role in modern engineering. They are everywhere—from manufacturing plants to aerospace. The global control system market is expected to reach $38 billion by 2027. This growth highlights their importance in enhancing efficiency and precision.

Various control systems are utilized, such as PID controllers, PLCs, and SCADA. PID controllers are particularly popular due to their simplicity and effectiveness. They help maintain desired output levels in industrial processes. However, tuning these controllers can be complex and often requires expert knowledge. On the other hand, PLCs are widely used for automation. They can handle multiple inputs and outputs. Yet, integrating them with legacy systems poses a challenge for engineers.

Data from the International Society of Automation shows that about 60% of control system failures stem from human error. Moreover, lack of training often leads to misconfiguration. As technology advances, engineers must adapt. The demand for skilled professionals is increasing. Despite the challenges, control systems remain crucial in driving innovation. Their evolution mirrors the growing complexity in engineering tasks.

PID control systems play a crucial role in modern industrial automation. They help maintain stability in various processes. According to a report by the International Society of Automation, nearly 90% of control systems rely on PID controllers. This statistic highlights their widespread use and importance in keeping operations running smoothly.

PID controllers consist of three components: Proportional, Integral, and Derivative. By adjusting these elements, engineers achieve desired outcomes. However, tuning PID parameters can be challenging. Poor tuning leads to oscillations or slow responses. A perfect balance is hard to achieve, and operators often face unexpected difficulties.

In dynamic environments, PID systems can struggle. For instance, a temperature control system may react slowly to abrupt changes. This lag can impact product quality. Engineers often need to revisit and refine their control strategies. Despite their popularity, PID controllers are not always a one-size-fits-all solution. As technology evolves, new strategies emerge, prompting a need for ongoing reflection and adaptation in engineering practices.

| Control System | Key Features | Application Areas | Advantages |

|---|---|---|---|

| PID Control | Proportional, Integral, Derivative | Industrial Automation | Simple implementation, effective for many processes |

| Fuzzy Logic Control | Handles uncertain and imprecise systems | Consumer Electronics, HVAC | Robust against noise, adaptable to changing conditions |

| Model Predictive Control | Uses model of system for prediction | Chemical Processes, Robotics | Optimizes performance, handles multi-variable systems |

| Adaptive Control | Adjusts parameters in real-time | Aerospace, Automotive | Responds to changes in system dynamics |

| Robust Control | Maintains performance despite uncertainties | Manufacturing, Robotics | High reliability, effective in uncertain environments |

| Linear Control | Models systems with linear equations | Electrical Systems, Mechanical Systems | Simplicity, easier analysis |

| Nonlinear Control | Handles nonlinear dynamics | Complex Systems, Robotics | Can model real-world systems more accurately |

| Data-Driven Control | Utilizes machine learning and data analytics | IoT Systems, Smart Grids | Can adapt to new data, continuous learning |

| Distributed Control Systems | Multi-agent coordination | Process Automation, Smart Cities | Flexible, scalable architecture |

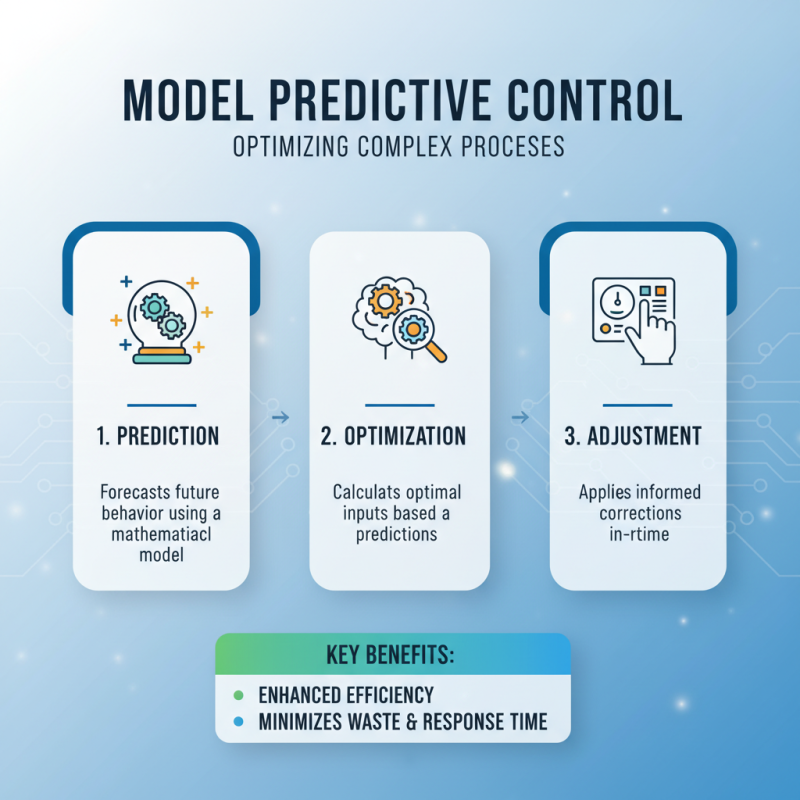

Model Predictive Control (MPC) stands out as a cutting-edge technique in modern engineering. It excels in optimizing complex processes by predicting future behavior. Using a mathematical model, it forecasts the outcomes based on current inputs. This approach allows engineers to anticipate changes and make informed adjustments. Efficiency is significantly enhanced by reducing response times and minimizing resource waste.

Tips: Involve team members when developing models. Their insights can enrich the predictive accuracy and create a more robust control system.

Another advantage of MPC is its flexibility. It adapts to nonlinearities and constraints imposed by real-world systems. However, this sophistication can come at a cost. Model development requires precision and attention to detail. Engineers must ensure that the data used is reliable. Small errors can lead to significant deviations in control performance.

Tips: Regularly validate your models against real data. This practice can help catch inaccuracies early and maintain control effectiveness.

Despite its strengths, MPC is not without challenges. The computational power needed can strain resources. Implementing MPC in resource-limited environments may require additional trade-offs. Nonetheless, its potential for enhancing process efficiency cannot be overlooked.

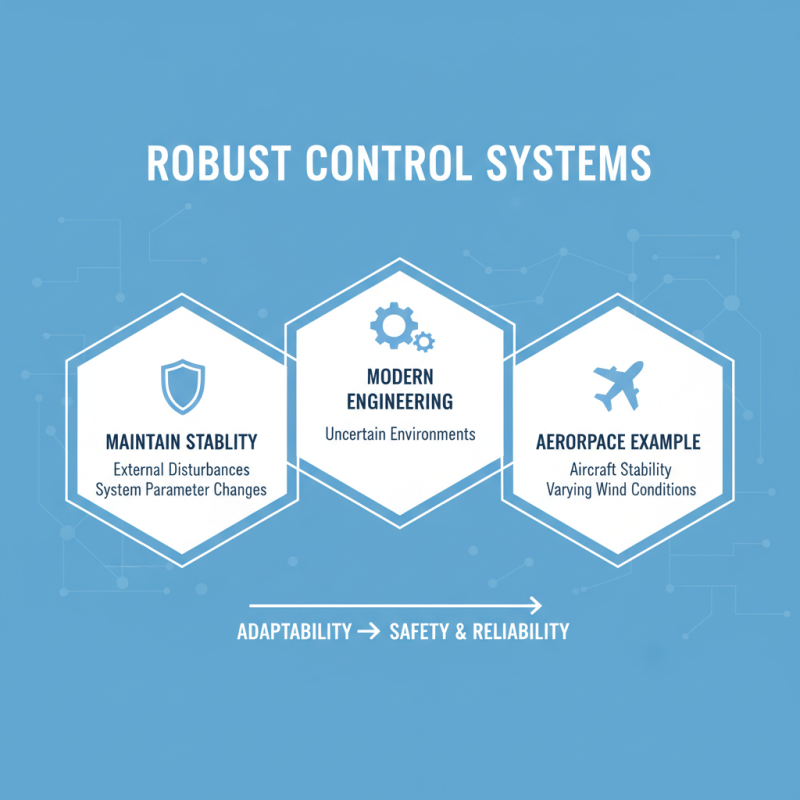

Robust control systems play a crucial role in modern engineering, especially in uncertain environments. These systems are designed to maintain stability despite external disturbances or changes in system parameters. For instance, in aerospace engineering, robust controls help manage aircraft stability under varying wind conditions. This ability to adapt is essential for safety and reliability.

Tips: Always consider environmental factors when designing control systems. Unpredictable elements can affect system performance.

In industrial automation, robust control systems ensure consistent production quality. Small fluctuations in input can lead to significant variations in output. By using robust design techniques, engineers can minimize these variations. However, achieving optimal robustness is challenging. It requires extensive testing and validation.

Tips: Involve cross-disciplinary teams for better insights. Different perspectives can enhance system design. Regularly review system performance to identify potential improvements.

Distributed Control Systems (DCS) play a crucial role in modern engineering. They allow large-scale operations to function efficiently and effectively. By distributing control tasks across various nodes, DCS can manage complex processes in real time. This decentralization enhances reliability and flexibility, allowing systems to adapt quickly to changing conditions.

In a DCS, each control unit operates independently but communicates seamlessly with others. This communication is vital for maintaining system coherence. For example, in a power plant, DCS can monitor and manage multiple generators and turbines. Each component can react instantly to fluctuations in demand or supply. However, the complexity of these systems can lead to unexpected challenges. If one node fails, it may cause a ripple effect throughout the entire operation.

Moreover, implementing DCS can be resource-intensive. Engineers need to ensure that all components are compatible. Training personnel to effectively operate and troubleshoot these systems is critical. Without proper training, even the best-designed DCS can falter. Recognizing these potential pitfalls is essential for optimizing performance in large-scale operations. Embracing these challenges can ultimately lead to improved efficiency and greater control over engineering processes.