In today’s rapidly evolving technological landscape, the design and understanding of control systems have emerged as critical components in achieving optimal performance across various industries. According to a recent report by MarketsandMarkets, the global control systems market is projected to grow from USD 180 billion in 2020 to over USD 250 billion by 2025, reflecting a compound annual growth rate (CAGR) of about 7.5%. This growth underscores the burgeoning demand for sophisticated and efficient control mechanisms in sectors such as manufacturing, aerospace, automotive, and energy management.

Control systems are vital for enhancing operational efficiency and ensuring reliability in processes that require automation and precision. The integration of advanced technologies, such as artificial intelligence and machine learning, into control systems presents industries with new opportunities to optimize performance and reduce costs. For instance, the International Society of Automation reported that implementing modern control strategies could lead to savings of up to 30% in operational expenses for industrial processes. Understanding the principles behind these systems and how to design them effectively is essential for engineers and organizations striving to stay competitive and leverage the full potential of their technological investments.

As industries continue to push the boundaries of innovation, mastering the intricacies of control systems will not only facilitate enhanced performance but also drive sustainable practices and improve overall productivity. Therefore, this paper aims to provide insights into the fundamentals of control systems, their design principles, and best practices for achieving optimal performance in diverse applications.

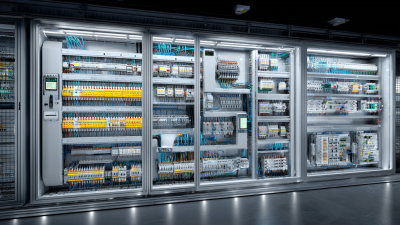

Control systems are essential for managing and manipulating the behavior of dynamic systems in various applications, such as manufacturing, robotics, and aerospace engineering. At their core, control systems utilize feedback loops to maintain desired outputs despite varying input or environmental conditions. By understanding the fundamentals of these systems—including components like sensors, actuators, and controllers—engineers can design more effective systems that enhance performance and reliability.

Tips: When designing a control system, always begin with a clear definition of the desired output and performance criteria. This will guide the selection and tuning of your control strategy, whether it's proportional, integral, or a combination of techniques. Additionally, consider the potential external disturbances that could affect system stability, and incorporate robust design principles to mitigate these risks.

Moreover, it is crucial to evaluate the system's response through simulations before actual implementation. Tools like MATLAB or Simulink provide valuable insights into how control strategies will perform under different scenarios. Regularly revisiting and refining your design based on real-world feedback will lead to continuous improvement and help achieve optimal performance over time.

Control systems are essential for regulating and optimizing various processes across diverse industries. Understanding the key components and functionalities of these systems is crucial for achieving optimal performance. At the heart of a control system are sensors, controllers, and actuators. Sensors collect real-time data about system variables, while controllers process this information to make decisions. Actuators implement these decisions by adjusting system inputs or outputs. According to a report by the International Society of Automation, the global market for control systems is projected to reach $23 billion by 2027, highlighting the growing importance of these technologies in enhancing operational efficiency.

To maximize the performance of a control system, it is vital to focus on proper design and integration of feedback loops. Feedback loops allow for continuous monitoring and adjustments based on performance metrics, ensuring that the system adapts to changing conditions. A study published in the Journal of Process Control noted that systems employing advanced feedback mechanisms can improve performance by up to 30%.

Tips for optimizing control systems include regularly calibrating sensors to ensure accuracy, implementing predictive maintenance strategies to foresee potential failures, and using simulation tools for better design insights. Additionally, training personnel on system functionalities can significantly enhance operational responsiveness, leading to improved overall performance and efficiency in control system operations.

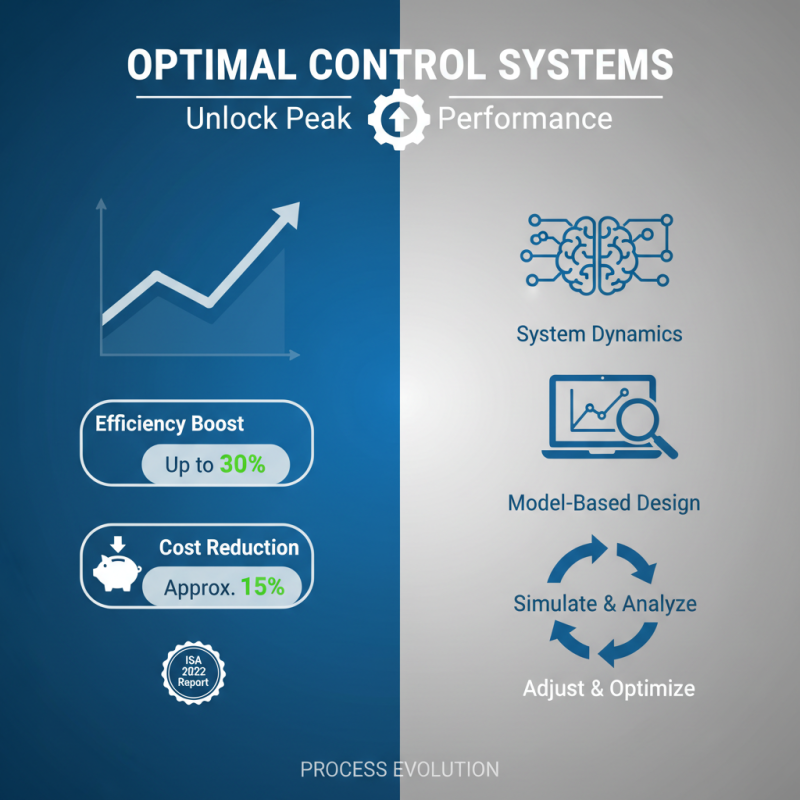

This chart illustrates key performance metrics of control systems, including response time, stability, overshoot, and settling time, providing insight into their optimal performance capabilities.

Effective control system design is essential for optimizing the performance of various applications, ranging from industrial automation to aerospace engineering. According to a 2022 report by the International Society of Automation, well-designed control systems can enhance process efficiency by up to 30% while reducing operational costs by around 15%. One of the central principles in achieving optimal performance lies in understanding the dynamics of the system, which includes the interactions between its components and external influences. Utilizing model-based design approaches allows engineers to simulate different scenarios, identify potential bottlenecks, and adjust parameters proactively.

Another critical design principle is feedback control, which plays a pivotal role in maintaining system stability and performance. Implementing advanced algorithms such as PID (Proportional-Integral-Derivative) control can significantly enhance responsiveness and accuracy in dynamic environments. A study published in the Journal of Control Engineering in 2023 highlighted that incorporating smart feedback mechanisms could improve system reliability by 25%, targeting real-time adjustments to counteract disturbances. Emphasizing the importance of parameter tuning and system identification techniques can lead to sustained performance improvements and adaptability in increasingly complex control scenarios.

Understanding system stability and response characteristics is crucial in the design of control systems for optimal performance. Stability generally refers to the ability of a system to return to equilibrium after a disturbance. According to a report by the National Institute of Standards and Technology (NIST), 80% of control system failures are attributed to issues with stability. In practical terms, a stable system is one where small perturbations do not lead to large deviations, allowing for predictable operation. Engineering approaches, such as root locus and Nyquist criteria, offer ways to assess stability and design controllers that ensure robust performance under varying conditions.

Response characteristics, on the other hand, encompass how a system reacts to inputs over time. Key metrics such as rise time, settling time, and overshoot are vital in evaluating performance. Data from the International Society of Automation indicates that optimal rise times can significantly enhance system responsiveness, improving efficiency in industrial applications by up to 30%. Furthermore, controlling the overshoot within desired limits ensures that the system remains not only effective but also safe to operate. By carefully analyzing these characteristics and employing advanced control strategies, engineers can design systems that not only maintain stability but also optimize performance across various operating conditions.

| Control System Type | Stability Criteria | Response Characteristics | Optimal Performance Indicators |

|---|---|---|---|

| PID Control | BIBO Stability | Fast Settling Time | Minimized Overshoot |

| Lead Compensation | Root Locus Analysis | Improved Phase Margin | Enhanced System Response |

| Lag Compensation | Stability Margins | Slow Response Speed | Steady-State Error Reduction |

| State Space Control | Eigenvalue Analysis | Multi-Variable Control | Quick Feedback Response |

| Robust Control | Robust Stability | Uncertainty Handling | Maximized Robustness |

Evaluating and optimizing control system designs is crucial for enhancing performance across various industrial applications. According to a report by the International Society of Automation, effective control system design can improve operational efficiency by up to 30%, demonstrating the significant impact that optimization can have on resource allocation and energy use. Key techniques such as model predictive control (MPC) and robust control strategies enable engineers to anticipate system behaviors and adjust parameters dynamically, reducing overshoot and settling times while maintaining stability.

Another method widely recognized in the industry is the use of simulation software to analyze control system responses before implementation. A study published in the Journal of Process Control indicated that simulations could reduce prototype testing times by approximately 40%, allowing engineers to iterate designs more quickly and effectively. Additionally, employing advanced metrics such as the Integral of Time-weighted Absolute Error (ITAE) during evaluation can help quantify performance improvements and guide subsequent design adjustments, ensuring that the systems not only meet but exceed predefined performance standards.