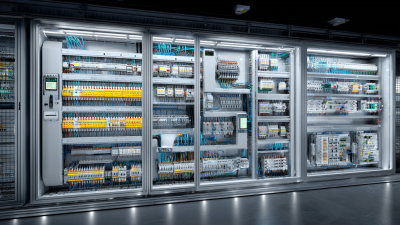

In today's rapidly evolving manufacturing landscape, the concept of World Industrial Automation has taken center stage, transforming traditional processes into highly efficient, digitally-driven operations. As businesses strive to stay competitive, implementing smart automation strategies is no longer optional but essential for success. This blog will explore ten critical digital tips that can help organizations navigate the complexities of industrial automation. From leveraging data analytics to embracing the Internet of Things (IoT), these actionable insights will empower manufacturers to unlock the full potential of their operations. Whether you are a small enterprise or a large corporation, understanding and applying these essential strategies will be key to thriving in the automated world of tomorrow.

Join us as we delve into the pivotal steps towards achieving seamless integration and optimal productivity in the realm of World Industrial Automation.

The integration of IoT solutions in industrial automation is paramount for achieving enhanced efficiency and productivity. By leveraging the power of connectivity and data analytics, businesses can unlock unprecedented operational insights. One effective strategy is to establish a robust data management framework. This involves collecting real-time data from sensors and devices, enabling organizations to monitor processes and make informed decisions swiftly.

Another essential tip is to invest in training and development for your workforce. Equipping employees with the necessary skills to understand and utilize IoT tools will foster a culture of innovation. Empowered teams can effectively troubleshoot issues and identify opportunities for process optimization, ultimately driving performance improvements.

Additionally, embracing a phased implementation approach can help mitigate risks associated with integrating new technologies. Start by identifying pilot projects that align with strategic goals, allowing for gradual testing and refinement. This not only eases the transition but also facilitates feedback loops that can guide future initiatives, ensuring a more comprehensive adoption of IoT solutions in your industrial automation endeavors.

| Tip No. | Tip | Description | Implementation Impact |

|---|---|---|---|

| 1 | Invest in Sensors | Implement sensors for real-time data collection. | Increases data accuracy and operational visibility. |

| 2 | Utilize Cloud Computing | Leverage cloud solutions for data storage and processing. | Enhances scalability and collaboration. |

| 3 | Implement Predictive Maintenance | Use analytics to predict equipment failures before they occur. | Reduces downtime and maintenance costs. |

| 4 | Adopt Automation Technologies | Integrate robotics and automated systems in production lines. | Boosts productivity and consistency. |

| 5 | Focus on Cybersecurity | Implement robust cybersecurity measures to protect data. | Safeguards against data breaches and cyber threats. |

| 6 | Enhance Workforce Training | Provide continuous training on digital tools and technology. | Improves employee efficiency and adaptability. |

| 7 | Integrate IoT Devices | Connect devices to gather comprehensive operational data. | Facilitates better decision-making and responsiveness. |

| 8 | Utilize Artificial Intelligence | Apply AI for data analysis and optimization. | Maximizes operational efficiency through data-driven insights. |

| 9 | Optimize Supply Chain | Streamline supply chain operations with digital tools. | Enhances logistics and reduces costs. |

| 10 | Monitor Key Performance Indicators (KPIs) | Establish metrics to track progress and performance. | Informs strategic adjustments and improvements. |

In an era where the volume of data is soaring, organizations must harness the power of big data analytics to inform their automation processes. According to recent findings, over 90% of businesses recognize the importance of data-driven decision-making, yet only a fraction effectively leverage the vast amounts of data at their disposal. The integration of advanced analytics into automation not only enhances operational efficiency but also empowers real-time decision-making. A study highlights that companies using AI in their analytics process can reduce decision-making time by nearly 30%, showcasing the pivotal role that timely insights play in a swiftly changing industrial landscape.

Furthermore, the application of AI and machine learning within data analytics processes illuminates actionable insights that were previously obscured by traditional analysis methods. As outlined in a recent report, 75% of firms that implemented AI for data analytics experienced significant improvements in accuracy and speed. This not only streamlines workflows but also supports a culture of continuous improvement within organizations, driving digital transformation. By leveraging these essential techniques, businesses can unlock heightened capabilities in their automation efforts, fostering innovation and establishing a competitive edge in the dynamic market.

The global supply chain analysis market is projected to grow from $11.08 billion in 2025 to $32.71 billion by 2032, with a remarkable compound annual growth rate of 16.7%. This escalating growth emphasizes the need for organizations to optimize their supply chain management strategies through digital integration and automation technologies. By employing real-time data and analytics, businesses can enhance their decision-making processes, ultimately leading to increased efficiency and productivity across the entire supply chain.

Moreover, the rise of smart manufacturing is inherently linked to advancements in big data, IoT, and 5G networks. As these technologies become more integrated, the sheer volume of structured and unstructured data will continue to surge, offering unprecedented opportunities for businesses to leverage insights for smarter operations. Big data applications will play a pivotal role in this transformation, enabling manufacturers to refine their processes, predict demands, and respond swiftly to dynamic market conditions. Harnessing these emerging trends will not only drive growth but also establish a more resilient and agile supply chain anticipated for the upcoming decade.

This chart illustrates the impact of various digital technologies on supply chain management efficiency. The data reflects improvements in efficiency measured as a percentage increase over a period.

In the era of artificial intelligence, enhancing workforce skills is imperative for businesses to stay competitive. Automated environments require employees to adapt and develop new skill sets to meet the evolving demands of their roles. One essential tip is to implement continuous training programs that integrate AI tools. This not only helps employees grasp AI technologies but also fosters a culture of lifelong learning within the organization.

Another critical strategy is to leverage AI for personalizing training experiences. By using data analytics, companies can identify skill gaps and tailor training modules to address these deficiencies. This targeted approach increases the relevance of training programs, making them more valuable to employees. Businesses also benefit from improved productivity as employees become better equipped to tackle complex tasks.

Finally, fostering collaboration between human and AI systems is key. Encourage employees to engage with AI technologies through hands-on projects, facilitating an environment where they can experiment and innovate. This not only enhances their skills but also helps bridge the skills gap that AI advancements have created in the workforce. By focusing on these essential strategies, organizations can enhance workforce capabilities and ensure sustainable growth in an automated future.

In the realm of industrial automation, evaluating return on investment (ROI) is critical for gauging the success of initiatives. According to a report by McKinsey & Company, companies that embrace automation can see a productivity increase of 20 to 30% within the first few years. However, this potential is only realized when organizations rigorously track key performance metrics, such as throughput, operational efficiency, and cost reduction. These metrics serve not just as indicators of success but as tools for continual improvement and strategic decision-making.

Additionally, a study conducted by the International Society of Automation reveals that organizations that implement data analytics within their automation systems report a 25% improvement in maintenance efficiency and a 15% decrease in downtime. By closely monitoring metrics like equipment effectiveness and production yield, companies can make informed adjustments and optimize their operations. Thus, establishing a robust framework for measuring these parameters is essential for achieving sustainable success in any automation initiative.