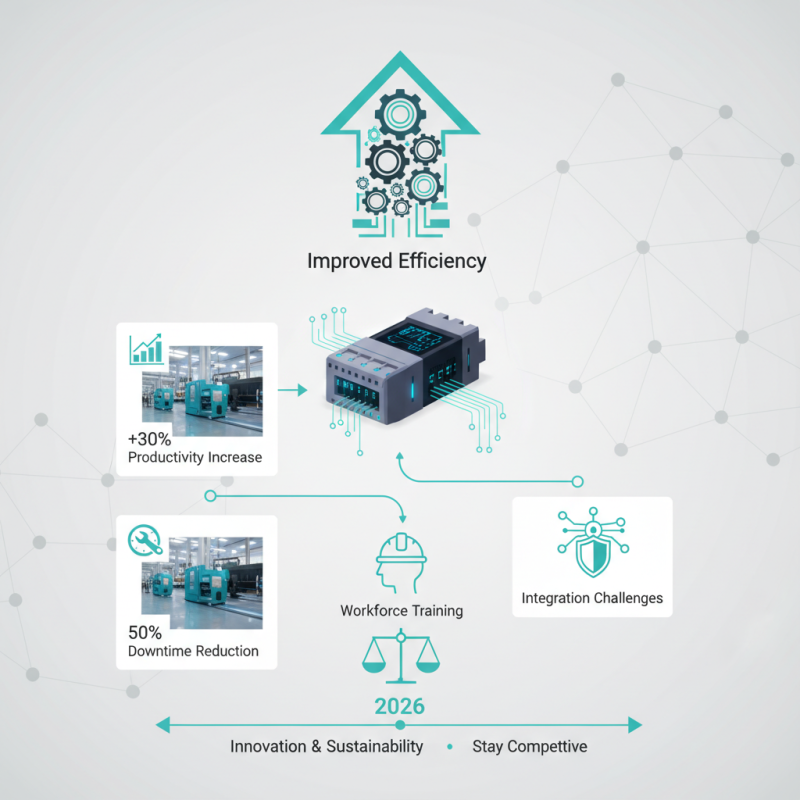

In the rapidly evolving landscape of 2026, Plc Automation continues to be a game-changer for industries seeking efficiency. According to a recent report by Automation World, companies that adopt Plc systems experience a 30% increase in productivity. This shift is not just about technology; it's about redefining operational strategies. As expert Lisa Thompson remarks, "Plc Automation is the backbone of modern manufacturing, driving innovation and sustainability."

Implementing Plc Automation can seem daunting. Not all organizations are prepared for this change. Challenges such as integration with existing systems can hinder progress. However, the potential benefits far outweigh these obstacles. Industry data indicates that firms embracing automation reduce downtime by up to 50%. This statistic urges businesses to rethink their approaches to manufacturing processes.

Moreover, companies often overlook training and employee adaptability. Investing in workforce education is crucial for successful Plc implementation. A well-trained team can maximize the benefits of automation technologies. Without proper training, companies risk losing valuable productivity gains. As we move through 2026, the focus on efficient Plc Automation will only intensify. Organizations need to act cautiously but decisively to stay competitive.

PLC (Programmable Logic Controller) automation significantly enhances operational efficiency in various industries. By 2026, companies can expect a marked improvement in productivity through its implementation. According to a recent industry report, businesses using PLC systems reported a 30% reduction in operational downtime. Such statistics underline the importance of integrating PLC automation in manufacturing lines.

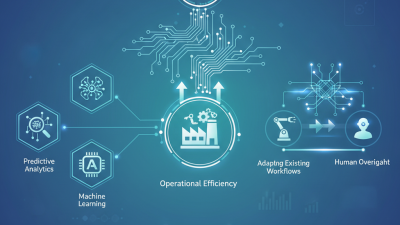

One key to maximizing efficiency is real-time data monitoring. PLC systems allow for constant tracking of production metrics. With this data, adjustments can be made instantly, reducing waste. An impressive 70% of manufacturers benefit from faster decision-making due to data-driven insights. This immediate feedback fosters a proactive approach to problem-solving.

Tips:

Regularly review PLC programming for potential improvements. Maintenance schedules should be strictly followed. Always train personnel on the latest PLC features. Continuous learning is vital for leveraging full capabilities. Reflect on areas that still show inefficiency. Automation presents challenges too. Sometimes systems may fail or lead to new complications. It's crucial to adapt and improve. Embracing PLC technology is only the beginning of the journey toward enhanced efficiency.

Modern PLC systems play a pivotal role in enhancing productivity. They feature advanced processing power, which allows for quick decision-making. These systems can manage various tasks simultaneously. This multifaceted approach reduces downtime significantly, streamlining production processes.

Tips: Embrace flexible programming. Customizable options enable easier adaptation to production changes.

Intuitive interfaces are essential. Operators should easily navigate system controls. User-friendly designs reduce the learning curve for new technicians. Yet, some users may struggle with the transition. Continuous training is crucial for effective implementation.

Tips: Regular updates are necessary. Keeping the software current prevents issues and boosts reliability.

Integrating IoT technology into PLC systems can connect numerous devices. This integration provides real-time data insights. However, some companies may overlook cybersecurity risks. Investing in protection measures is not just wise; it's essential.

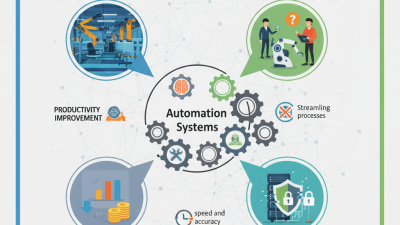

Implementing PLC automation requires careful planning and execution. Companies often overlook key integration steps. According to a 2022 industry report, 70% of manufacturers experienced delays due to inadequate automation strategies. This highlights the importance of a structured approach.

Begin with assessing current processes. Identify bottlenecks and inefficiencies. A detailed analysis can reveal where automation will have the most impact. For example, tasks with high manual intervention often lead to errors and slowdowns. Data shows that over 60% of work hours can be saved by automating repetitive tasks.

Next, choose the right PLC system. The right system can match your specific needs. Depending on the complexity of your operations, this decision can be daunting. Some companies might choose budget options that fail to deliver efficiency. Research indicates that 45% of businesses struggle with system compatibility post-implementation. Pilot tests are crucial here. They can uncover potential issues before full deployment. Ensure that your team receives proper training. Disengagement during the transition can diminish the intended benefits of automation.

In 2026, using PLC automation becomes critical for enhancing operational efficiency in industrial settings. Proper optimization of these systems leads to substantial improvements in productivity. Reports indicate that companies using optimized PLC systems can experience up to a 30% reduction in downtime. Yet, many still operate with outdated programming techniques, which can hinder overall performance.

Tips: Regularly review your PLC code. Simplified programming not only enhances speed but also improves troubleshooting. Validate your logic to avoid costly errors.

Staying updated with the latest industry standards can also play a crucial role. One study found that 65% of organizations that adopted new PLC technologies saw a 20% increase in output. However, resistance to change remains common. Many personnel stick to familiar processes instead of embracing innovation.

Tips: Encourage training sessions. Empower staff to adopt new tools and processes. This change fosters a culture of continuous improvement and efficiency.

Monitoring system performance in real-time is essential. Data analytics can uncover inefficiencies often overlooked. A staggering 70% of maintenance costs arise from unforeseen equipment failures. A proactive approach can mitigate these risks.

This bar chart illustrates the percentage improvement in operational efficiency across different automation sectors using PLC systems in industrial settings as projected for 2026.

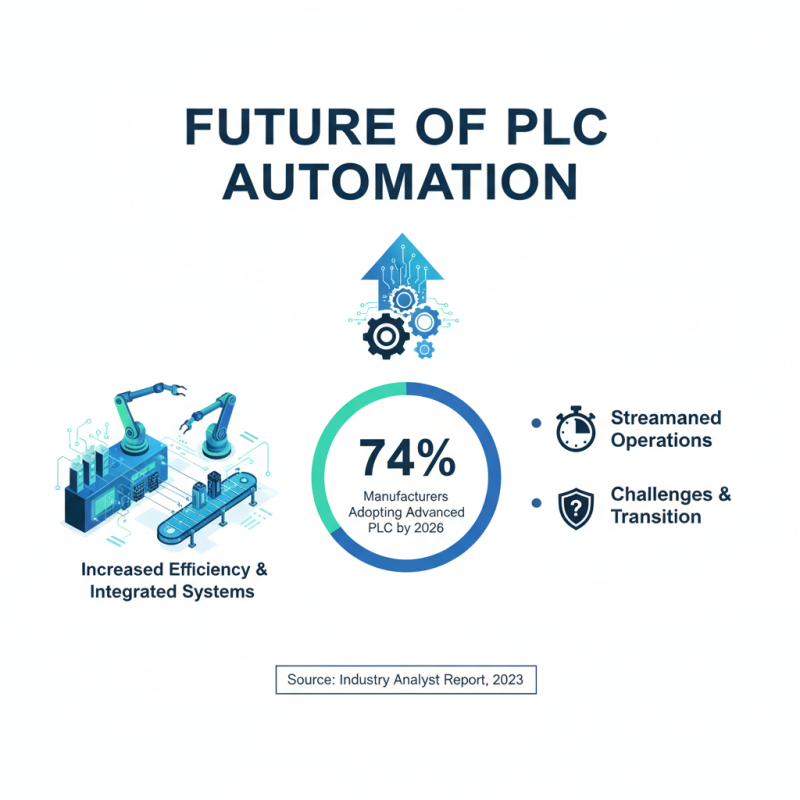

The future of PLC automation is promising. As companies aim for heightened efficiency, trends indicate a shift towards more integrated systems. According to a recent report by an industry analyst, 74% of manufacturers are expected to adopt advanced PLC technologies by 2026. This transition could streamline operations, but it also brings challenges.

Incorporating IoT capabilities into PLC systems can lead to smarter automation processes. A report by a leading consultancy highlights that IoT-enabled PLCs can improve operational efficiency by up to 30%. However, this integration is not without its pitfalls. Data security remains a major concern. Many organizations lack the necessary infrastructure to safeguard sensitive information. Training staff to effectively utilize these advanced systems poses another hurdle. It is crucial to invest in workforce development to fully realize these technological advancements.

Artificial intelligence will play a pivotal role in PLC automation. However, adopting AI comes with its complexities. While the potential for predictive maintenance is significant, many systems are still not optimized for machine learning. Research indicates that less than 40% of companies are currently leveraging AI capabilities within their PLCs. The road ahead requires a thoughtful approach to ensure that efficiency gains do not come at the cost of adaptability and security.