0102030405

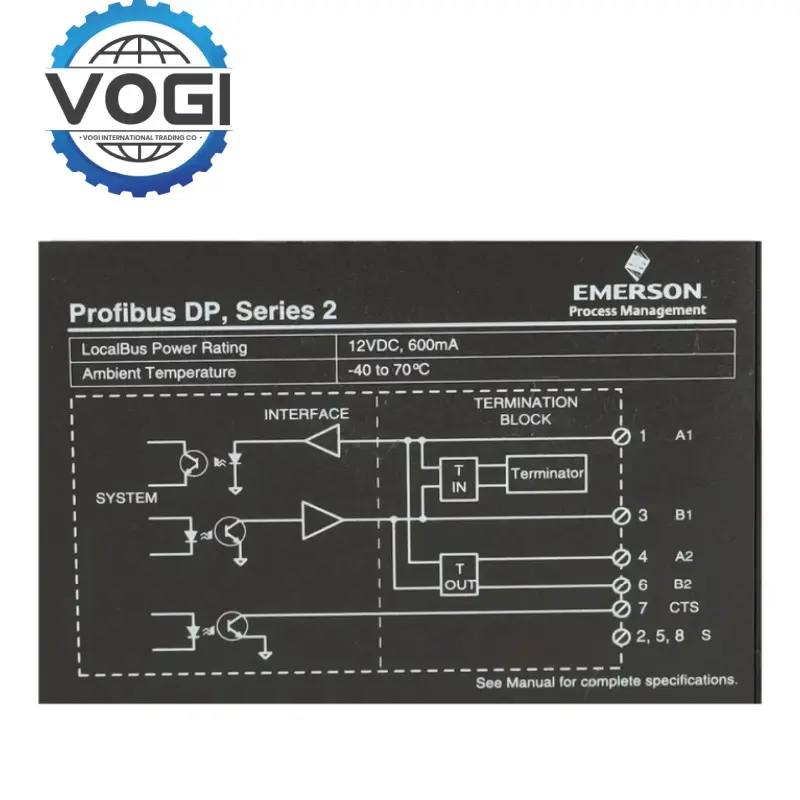

Emerson VE4014 KJ3243X1-BA1 12P2830X022 Series 2 ProfibusDP Card

Key SpecificationsVogi

1.Power input: 24VDC, redundant input supported (range: 18-30VDC)

2.Battery backup: no built-in battery backup, external UPS or redundant power supply is required.

3.Communication interface: WirelessHART + Ethernet, support Modbus TCP/IP protocol and industrial IoT integration.

4.Programmable inputs: 4 analog inputs

5.Relay output: 8-channel relay output (contact capacity: 2A/250VAC, support solenoid valve, motor control)

6.Operating temperature: **-40℃~+85℃**

7.Humidity range: 5%~95% (non-condensing)

8.Display and operation: No display, configured via DeltaV system or AMS Trex device

Freight Estimation(Part Of The Area)Vogi

|

Destination |

Freight |

|

Middle East |

$35 |

|

Southeast Asia |

$23 |

|

South Asia |

$45 |

|

South Africa |

$37 |

|

Europe and USA |

$24 |

|

Russia |

$41 |

FeaturesVogi

1.Industrial-grade power supply design: The Emerson VE4014 is a 24VDC redundant power input, adapting to grid fluctuation scenarios and guaranteeing uninterrupted operation for 7×24 hours.

2.Dual-mode communication fusion: WirelessHART and Ethernet synergize to solve wiring problems, while being compatible with new and old systems to reduce upgrade costs.

3.High-precision closed-loop control: 16-bit resolution acquisition of key parameters (e.g. pressure/temperature), supporting PID algorithm to optimize production stability.

4.Collaborative control of multiple devices: The Emerson VE4014 has 8 channels of independent outputs, realizing precise start/stop and interlock protection of production line devices and reducing manual intervention.

5.Extreme environment tolerance: The Emerson VE4014 is capable of stable operation from -40°C to 85°C, which is suitable for refineries, desert photovoltaic and other harsh scenarios.

6.Lightweight and maintenance-free: The modular and compact design of the Emerson VE4014, IP40 dustproof and waterproof, saves cabinet space and reduces operation and maintenance costs.

APPLICATIONSVogi

1.Industrial control:Equipment status monitoring (temperature/pressure/flow), dual-channel programmable input trigger relay control start/stop or alarm.

2.Energy management:Distribution system overvoltage/overcurrent protection, 5A 250V AC relay directly drives circuit breaker.

3.Environmental monitoring:Machine room temperature and humidity/fire smoke linkage control, wide temperature (-20°C~60°C) and high humidity (5%-95% RH) tolerance.

4.Equipment linkage:Production line multi-equipment collaboration (robot arm/conveyor belt), support 16-point I/O expansion and logic programming.