0102030405

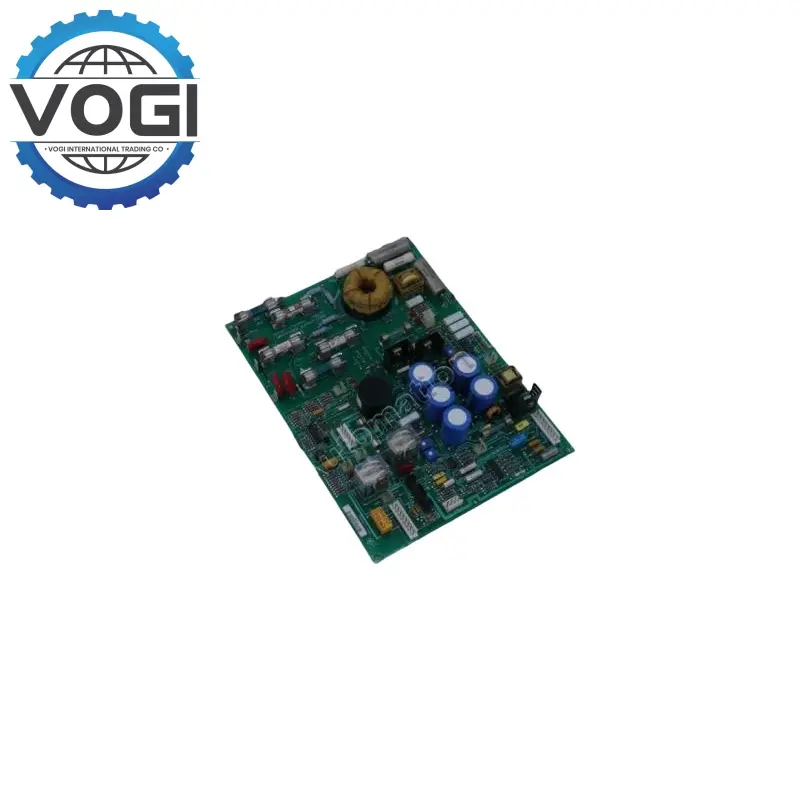

GE 531X111PSHARG1 Power Supply Board

Key SpecificationsVOGI

Input voltage: 24VDC ±10%

Output current: 2A / channel (resistive load)

Isolation method: optoelectronic isolation

Insulation resistance: ≥100MΩ (500VDC)

Common mode rejection ratio: ≥120dB (DC-60Hz)

Number of channels: 16 digital inputs / 16 digital outputs

Response time: ≤1ms (input), ≤2ms (output)

Refresh cycle: 5ms (configurable)

Anti-interference ability: in accordance with IEC 61000-4 standard

EMC compatibility: EN 61000-6-2 (industrial environment)

Installation method: standard DIN rail installation

Casing material: flame retardant ABS engineering plastic

Operating temperature: -40°C to +85°C

Storage temperature: -40°C to +95°C

Relative humidity: 5% to 95% (non-condensing)

Vibration resistance: 10-2000Hz, 1g (IEC 60068-2-6)

Shock resistance: 15g, 11ms (IEC 60068-2-27)

Communication interface: Redundant Ethernet (10/100Mbps)

Protocol support: Modbus TCP, Profinet, Ethernet/IP

I/O scan cycle: ≤1ms (typical value)

Maximum number of nodes: 256 (network configuration)

Key FeaturesVOGI

High reliability: GE 531X111PSHARG1 uses high-quality electronic components and advanced manufacturing processes. It can operate stably in harsh industrial environments and has strong anti-interference capabilities, which can effectively reduce system failures caused by electromagnetic interference, power supply fluctuations and other factors.

Flexible input and output configuration: GE 531X111PSHARG1 has 16 digital input and 16 digital output channels, which can be flexibly configured according to actual industrial control needs and adapt to a variety of different control scenarios.

Fast response: The response time is short, the input channel is ≤1ms, and the output channel is ≤2ms. 531X111PSHARG1 can quickly sense changes in external signals and respond in time, meeting industrial control tasks with high real-time requirements, such as equipment control and motion control on high-speed production lines.

Good compatibility and openness: Supports multiple communication protocols, such as Modbus TCP, Profinet, Ethernet/IP, etc., can easily communicate and integrate with other devices or systems, and can seamlessly connect with PLCs, DCS systems, host computer monitoring software, etc. from different manufacturers to achieve integration and collaborative work of industrial automation systems.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$35 |

|

Southeast Asia |

$15 |

|

South Asia |

$45 |

|

South Africa |

$37 |

|

Europe and USA |

$24 |

|

Russia |

$42 |

APPLICATIONVOGI

Petrochemical industry: In the process of oil refining and chemical production, it is used to monitor and control various process parameters such as temperature, pressure, flow, etc.

Power industry: In power plants, substations and other scenarios, it can be used for automatic control and monitoring of power systems.

Metallurgical industry: In the metallurgical production process of steel, non-ferrous metals, etc., it is used to control key equipment such as furnaces and rolling mills.

Pharmaceutical industry: In the process of drug production, production equipment and processes are strictly controlled and monitored to ensure that the quality and safety of drugs meet the standards.

Automobile manufacturing industry: On the automobile production line, it is used to control the movement of robots, the parameters of welding equipment, the parameters of coating processes, etc.