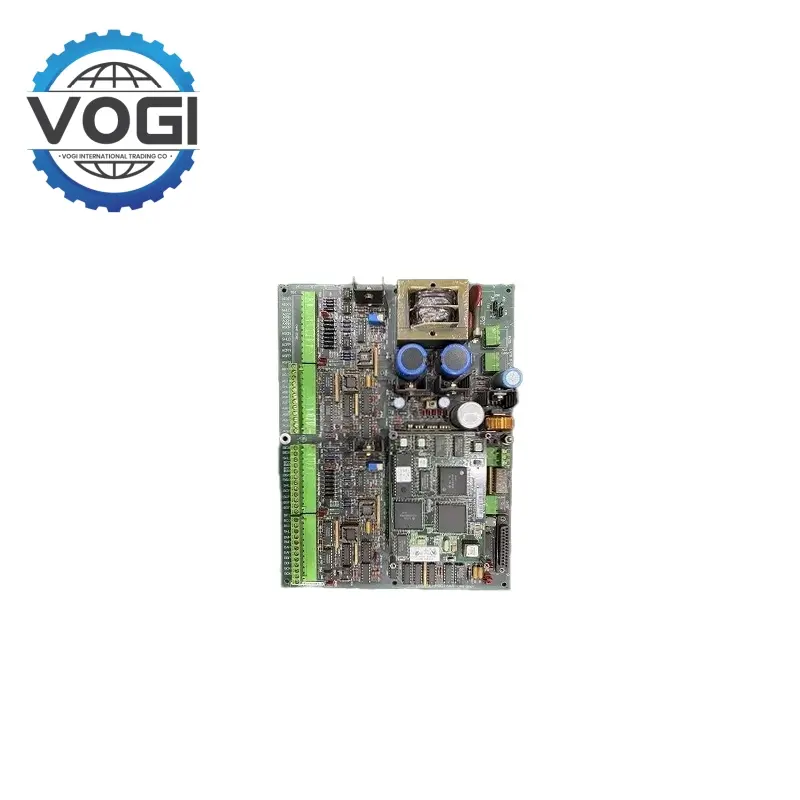

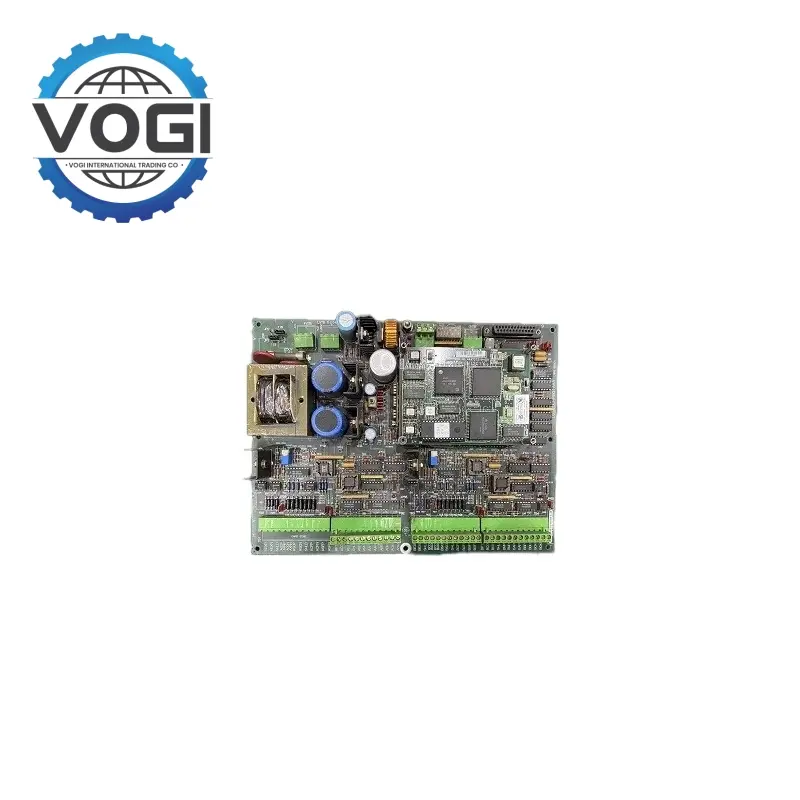

GE DS200LRPBG1AAA Turbine control board

Key SpecificationsVOGI

Nominal Input Voltage: 24V DC.

Voltage Range: 20V to 30V DC.

Input Power: 24V DC;

Output Current per Channel: up to 10A per output channel.

Maximum Current: 30A for a complete group of channels.

Operating Temperature: -40°C to +70°C to ensure reliable operation in harsh industrial environments.

Storage Temperature:-40°C to +85°C .

Relative Humidity: 5% to 95%, non-condensing.

Vibration Resistance: Designed to withstand industrial-level vibrations commonly experienced in manufacturing, power generation, and oil & gas environments.

Shock Resistance: Built to handle industrial shock levels as specified by GE standards.

Key FeaturesVOGI

Stable Power and Precision Engineered: GE DS200LRPBG1AAA's circuitry requires stable power for operation, which it draws from its specialized hardware. State-of-the-art microprocessors and digital signal processors (DSPs) are at the heart of the device. These elements work in harmony, processing LAH stacks of data from several input sources at an incredible speed and precision. They are capable of executing complex signal conditioning, filtering, and transformation so that the device can interface with different industrial control requirements.

Widespread Interfaces Communication: GE DS200LRPBG1AAA has plentiful communication interface. It uses industry-standard protocols such as EtherNet/IP and OPC UA, enabling integration with contemporary automation infrastructures. Also, has serial ports to connect to legacy equipment, so its backward compatible. This enables communication with diverse sensors, actuators, and other control devices, creating a unified network for industrial control systems.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$59 |

|

Southeast Asia |

$48 |

|

South Asia |

$78 |

|

South Africa |

$63 |

|

Europe and USA |

$35 |

|

Russia |

$71 |

APPLICATIONVOGI

Power plant: used to control the gas turbine and steam turbine systems of hydropower stations to maintain stable operation and effective control of power generation equipment.

Industrial automation: servo motor position feedback elements can be used in some industrial automation equipment that requires high-precision position detection and speed control to provide accurate position and speed information for the control system.

Large mechanical equipment: For large mechanical equipment, in its control system, it can be used to monitor and control the operating status of the motor, thereby adjusting the parameters of the equipment and improving the operating efficiency and reliability of the equipment.