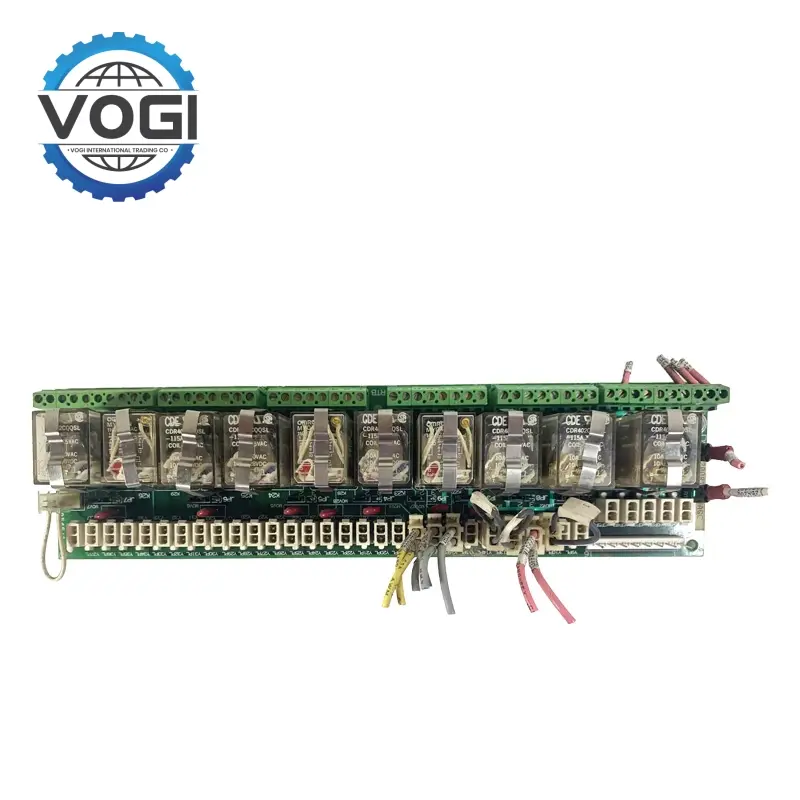

GE DS200RTBAG3AGC Relay Terminal Board

Key SpecificationsVOGI

Rated Voltage: 115 VDC.

Relay Coil Voltage: 110 VDC

Operating temperature range: -20℃ to +60℃

Humidity range: 5% to 95%

Insulation resistance: greater than 100MΩ

Number of Relays: 10 relays total

Resistor Protection: All relay I/Os are 130 VAC metal oxide varistors.

Internal Structure: Jumpers, RPL Links, Opt PL Connections, Stab Cnt, C1PL, Y9PL, and Terminals.

I/O Connections: 16-pin connector interface and 2-pin connector interface to LTBA board.

Key FeaturesVOGI

Signal Purity: GE DS200RTBAG3AGC purifies your signal by providing a component that ensures only relevant and true data is processed. It also provides high-resolution sampling and conversion capabilities, error minimization, and data integrity maintenance.

Flexible configuration options: The GE DS200RTBAG3AGC is equipped with convenient software or interfaces that allow operators to easily change parameters such as signal sampling rate, input/output mode and communication settings, allowing it to adapt to various industrial processes and complex multivariable control scenarios.

Communication capabilities: The GE DS200RTBAG3AGC supports a variety of industry-standard communication protocols such as Modbus, Profibus and Ethernet/IP, which makes it ideal for integration with other devices in industrial networks for real-time data exchange and remote monitoring.

Scalability: It is capable of connecting additional input/output modules and can be expanded to connect more sensors, actuators or other peripherals without complex rearrangement of the existing system configuration.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$43 |

|

Southeast Asia |

$31 |

|

South Asia |

$56 |

|

South Africa |

$46 |

|

Europe and USA |

$28 |

|

Russia |

$51 |

APPLICATIONVOGI

Power application: It can be used as a general module in various control and monitoring equipment in the power system to achieve stable operation and fault diagnosis of the power system.

Process control: DS200RTBAG3AGC can be used in process industries such as chemical, petroleum, and metallurgy to monitor and control various parameters in the production process, including temperature, pressure, flow, etc.

Remote monitoring and data acquisition: The module has an Ethernet interface, which can easily communicate with other devices to achieve remote monitoring and data acquisition functions.