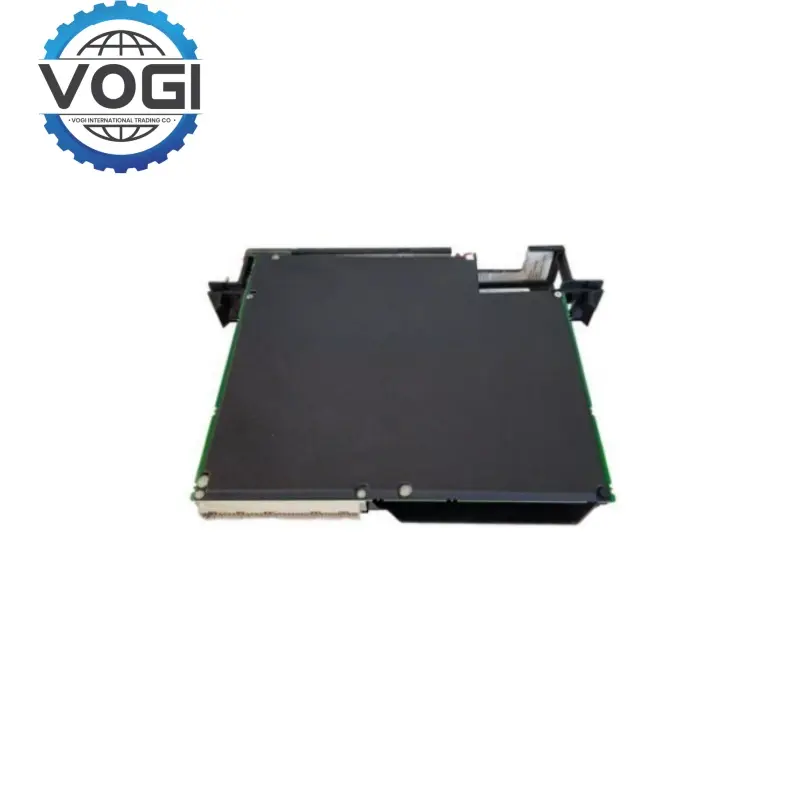

GE IC697CPM790 Central Processor Unit

Key SpecificationsVOGI

Power input: Mains power supply is 100 - 240VAC, frequency covers 50/60Hz.

Power consumption: about 40W.

Communication interface: Ethernet interface, supporting TCP/IP protocol.

Transmission rate is 10/100Mbps; configured with RS-232 and RS-485 serial ports.

Digital input: 32 digital input channels, input type is 24VDC.

Digital output: 32 digital output channels, output type 24VDC, single channel load capacity up to 0.5A.

Analog input: 8 analog input channels.

Analog output: 4 analog output channels.

Voltage output range: 0 - 10V.

Current output range: 4-20mA.

Operating Temperature: 0℃ to 60

Humidity range: 5% - 95% relative humidity.

Key FeaturesVOGI

High-performance processing capability: 32-bit floating-point computing capability, suitable for application scenarios requiring high computational precision and processing speed.

Rich input/output support: GE IC697CPM790 supports up to 12K discrete inputs and outputs to meet the needs of complex systems.

Multiple communication interfaces: Equipped with RS-485 compatible 15-pin D-type connector for easy communication with other devices.

Flexible Programming Support: GE IC697CPM790 Supports a variety of programming languages and methods, making it easy for users to customize according to their needs.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$51 |

|

Southeast Asia |

$15 |

|

South Asia |

$56 |

|

South Africa |

$46 |

|

Europe and USA |

$27 |

|

Russia |

$51 |

APPLICATIONVOGI

Power industry: The monitoring of power systems is mainly used in power facilities such as power plants and substations.

Petrochemical industry: Applied in multiple scenarios such as oil extraction, oil refining, and chemical production. The monitoring parameters include the temperature, pressure, and flow of chemical reactors. It can also be used for oil pipeline flow control and pump station operation management.

Metallurgical industry: In metallurgical industries such as steel and non-ferrous metal production, the automatic control of smelting equipment such as blast furnaces, converters, and electric furnaces is realized to improve product quality and production efficiency.

Papermaking industry: Used for the control of various links in papermaking production, concentration control in the pulping process, speed and tension control of paper machines, thickness control in the coating process, etc., to ensure the quality of paper and the continuity of production.

Water treatment industry: In water treatment facilities such as water treatment plants and sewage treatment plants, it is used for the control of water pumps and valves, as well as the monitoring and adjustment of water quality parameters, to achieve full automation and intelligence of the entire water treatment process.