0102030405

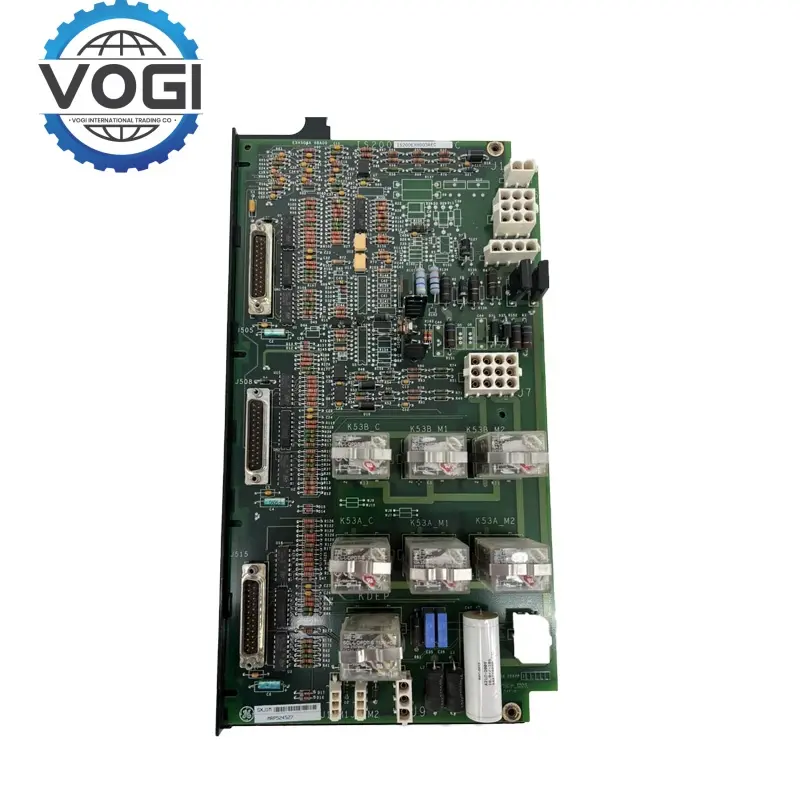

GE IS200EXHSG3AEC Exciter H.S.Relay Driver Board

Key SpecificationsVOGI

Power input: 24V DC, allowing ±10% voltage fluctuation, redundant power supply design.

Power consumption: 20W.

Communication interface: Dual 10/100BASE-TX Ethernet port, support Ethernet/IP and Modbus TCP protocol; RS-232C port for initial configuration and serial communication.

Relay configuration: 7 solid state relays to withstand 120V AC load, response time < 10ms.

Input type: 4 passive magnetic speed input, can monitor the speed of 2-2000 RPM; Eight differential voltage inputs are available.

Output type: 120V AC relay output to trigger main trip or excitation control action.

Operating temperature: -40°C to +85°C

Humidity range: 5%-95% RH

Protection level: IP20

Signal isolation: Input and output channels photoelectric isolation, isolation voltage ≥2500V AC.

Installation mode: Standard VME single slot (3U).

Key FeaturesVOGI

High-speed processing: GE IS200EXHSG3AEC Based on GE's dedicated ASIC chip, high-speed signal processing and real-time control can be achieved.

Redundancy design: Dual Ethernet ports support network redundancy to ensure uninterrupted communication; Hardware level fault self-diagnosis function.

Precise control:GE IS200EXHSG3AEC can accurately control the excitation current, maintain the generator terminal voltage and reactive power stability.

High reliability: wide operating temperature range and good isolation characteristics, adapt to harsh industrial environment, strong anti-electromagnetic interference ability.

Fast response: The short response time of the relay can quickly trigger an emergency shutdown in case of an exception.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$50 |

|

Southeast Asia |

$40 |

|

South Asia |

$67 |

|

South Africa |

$54 |

|

Europe and USA |

$30 |

|

Russia |

$61 |

APPLICATIONVOGI

Power generation industry: gas turbine and steam turbine control, to ensure the stable operation of generators. Precise control of generator excitation system to optimize power output.

Industrial automation: In the petrochemical industry, it is used for safety interlock control of key equipment such as pumps and compressors. : In power system, realize remote control of transformer tap-changer.

Renewable energy field: wind power and hydropower units connected to the grid control to ensure power quality; Charge and discharge management of energy storage system.