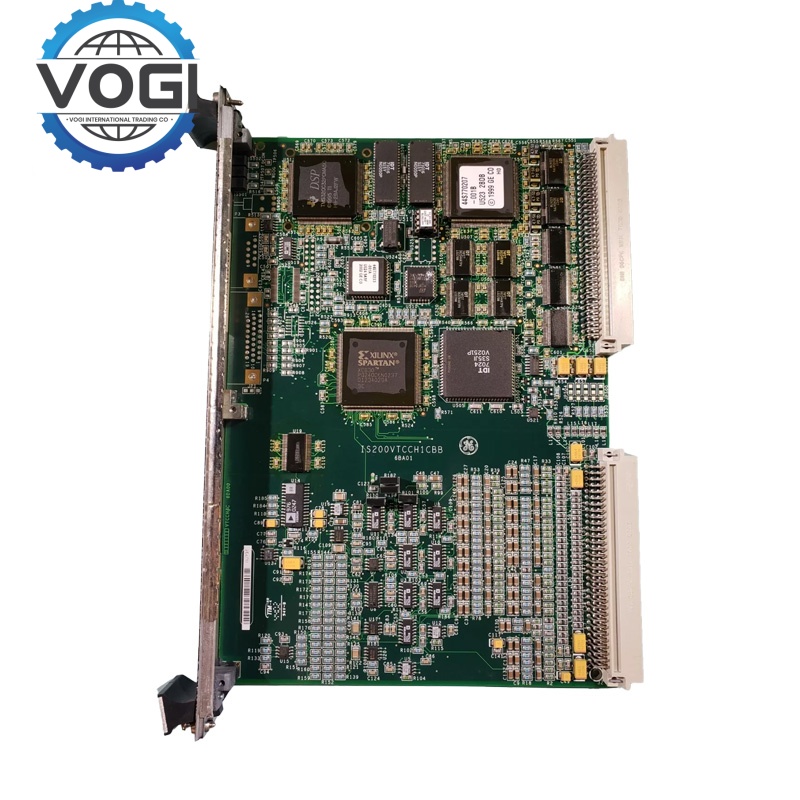

GE IS200VTCCH1C Thermocouple Input Board

Key SpecificationsVOGI

Main power supply: 24VDC±15%.

Input type: Supports E, J, K, S, T type thermocouples and mV signal input

Channel capacity: Single board supports 24 thermocouple inputs.

A/D conversion accuracy: 16-bit analog-to-digital converter, accuracy ±0.5% full scale.

Cold end compensation: Built-in dual cold end reference device, supports local or remote compensation, compensation accuracy ±2°F.

Communication interface: Communicates with the main controller via VME bus, supports IONet

Temperature range: -40°C to +85°C.

Humidity range: ≤95% RH.

Key FeaturesVOGI

High-precision thermocouple signal processing:Built-in 16-bit A/D converter, accuracy up to ±0.5% full scale, supports cold end compensation, compensation accuracy ±2°F.

High-density channel configuration:A single card supports 24 thermocouple inputs, which needs to be expanded with TBTCTerminal Board, and can connect to sensors up to 300 meters away.

High-reliability redundant design:GE IS200VTCCH1C supports simplex or triple redundant mode, suitable for critical control systems.

Intelligent fault diagnosis and protection:Automatically detects abnormal thermocouple signals, supports channel fault isolation and online diagnosis, and ensures system stability.

Hardware-enhanced design:Equipped with Xilinx Spartan FPGA, digital signal processor and dual-port SRAM, GE IS200VTCCH1C supports high-speed data processing.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$51 |

|

Southeast Asia |

$40 |

|

South Asia |

$67 |

|

South Africa |

$54 |

|

Europe and USA |

$30 |

|

Russia |

$61 |

APPLICATIONVOGI

Metallurgy and Manufacturing:Temperature control of blast furnaces and furnaces in steel plants, and thermal management of precision manufacturing equipment.

Water Treatment and Environmental Protection:GE IS200VTCCH1C High-temperature process monitoring of sewage treatment plants and water purification plants, supporting continuous emission monitoring.

Power and Energy:Thermal control protection of gas turbines and steam turbines, real-time monitoring of key component temperatures.

Petrochemicals:Temperature monitoring of high-temperature reactors and distillation towers in refineries and chemical plants, GE IS200VTCCH1C supporting multi-channel high-precision data acquisition.

Industrial Automation:Environmental temperature monitoring of production line equipment, with redundant systems to improve reliability.