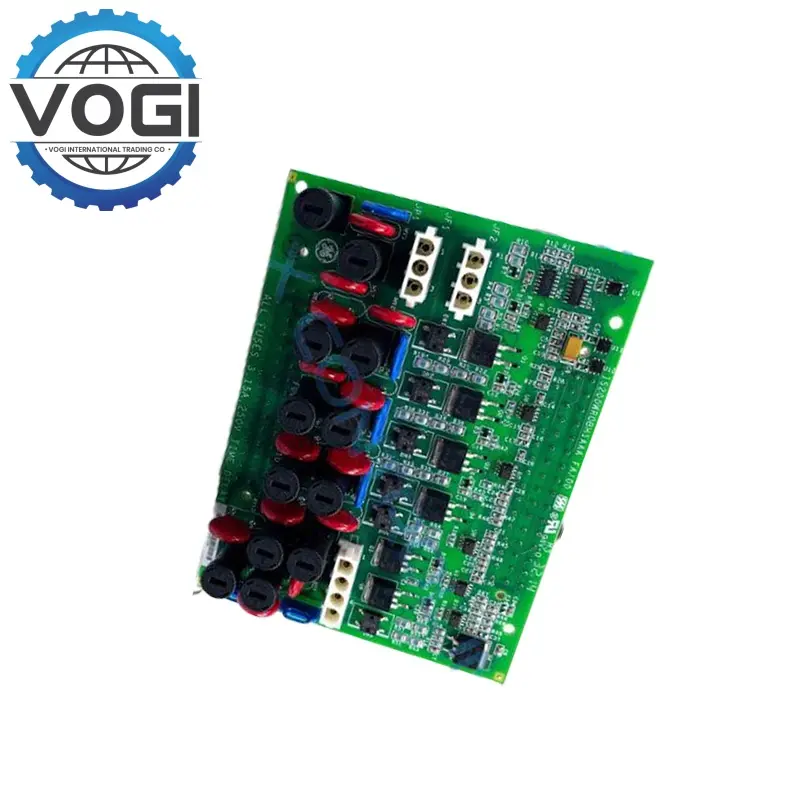

GE IS200WROBH1AAA Wrob Relay Fuse And Power Sensing Board

GE IS200WROBH1AAA Technical ParametersVOGI

Input/output: 8 relay outputs (6 fuse detection + 1 dedicated)

Voltage: 24V DC/48V DC

Communication interface: VME backplane, compatible with RS-422, Ethernet (10Mbps), supports Modbus protocol

Environmental indicators: Humidity 5%-95% (non-condensing)

Vibration resistance: 5-500Hz, 10g peak

GE IS200WROBH1AAA Key FeaturesVOGI

Relay Control and Power Management

Multi-channel Signal Processing: GE IS200WROBH1AAA supports 8 relay outputs (6 fuse detection power supplies + 1 dedicated power supply), the default fuse value is 3.15A, and can directly drive turbine actuators (such as fuel valves, solenoid valves), with a response time of <5ms.

Power Monitoring and Protection: GE IS200WROBH1AAA monitors the power status in real time, and prevents electromagnetic interference through optical isolation technology (EMC level up to IEC 61000-4-3) to ensure signal integrity.

System Compatibility and Redundancy Design

Adaptation to Mark VIe Architecture: GE IS200WROBH1AAA is compatible with VME backplane, supports simplex, redundant (duplex) or triple redundant (TMR) configuration, and can be seamlessly integrated into gas/steam turbine control systems to ensure high availability in critical scenarios.

Hot-swap maintenance: GE IS200WROBH1AAA supports online replacement of faulty modules, with an average repair time of less than 15 minutes, reducing downtime.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$51 |

|

Southeast Asia |

$17 |

|

South Asia |

$65 |

|

South Africa |

$55 |

|

Europe and USA |

$31 |

|

Russia |

$62 |

GE IS200WROBH1AAA Core AdvantagesVOGI

High reliability: Industrial-grade components and jumper-free design reduce the risk of human error and adapt to harsh environments.

Efficient integration: Plug-and-play design supports rapid deployment and expansion, and can work with other GE modules (such as IS200TDBSH6ABC).

Precise control: 12-bit resolution analog-to-digital conversion ensures parameter monitoring accuracy (temperature error <±0.5°C, pressure error <±1%).