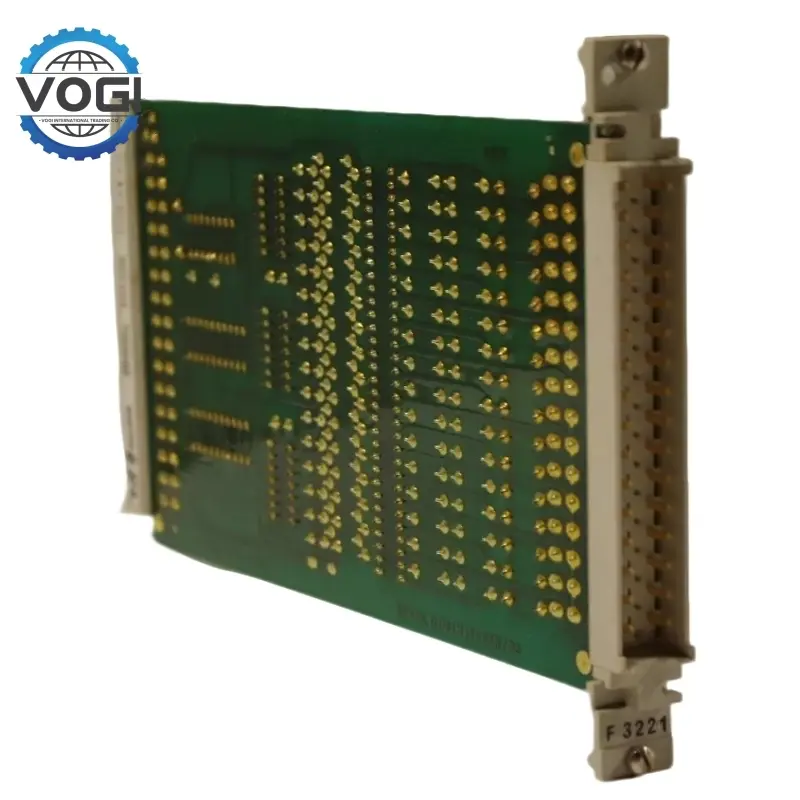

HIMA F3221 16-fold input module

Key SpecificationsVogi

Digital input: 24V DC dry contact

Analog input: 0-10V DC / 4-20mA, 4 channels;

Digital output: relay output (AC 250V/5A, DC 24V/10A), 8 channels.

Response time: ≤5ms, meeting the requirements of high-speed safety circuits.

Protection level: IP67 (dustproof and waterproof)

Supply voltage: DC 24V ±15%, (-30% ~ +25%).

Operating temperature: -25°C ~ +60°C;

Storage temperature: -40°C ~ +70°C.

Standard DIN rail installation: size 120×80×60mm;

Key FEATURESVogi

Signal acquisition and processing: that is, the module accurately collects on-site digital signals, reduces noise and interference through signal processing such as filtering and de-jittering, ensures the stability and accuracy of the input signal, and provides reliable digital input information for the control system;

Fault diagnosis: built-in fault detection function, real-time monitoring of the module's operating status and abnormal conditions of the input signal, reducing production interruptions and losses caused by equipment failures.

Configurability: supports flexible configuration. Users can use corresponding software tools to set parameters, configure channels, customize functions, etc. according to specific industrial application requirements.

Redundancy: In some occasions with extremely high reliability requirements, HIMA F3221 can be used in conjunction with other redundant modules to effectively form a redundant input system. Ensuring the continuous and stable operation of all systems can improve the availability and fault tolerance of the entire system.

Freight Estimation(Part Of The Area)Vogi

|

Destination |

Freight |

|

Middle East |

$35 |

|

Southeast Asia |

$15 |

|

South Asia |

$45 |

|

South Africa |

$37 |

|

Europe and USA |

$24 |

|

Russia |

$42 |

applicationVogi

Machine tool applications: emergency stop circuits, crane limit switches, etc., multi-condition safety interlocks, are realized through 16 digital inputs, and the SIL2/PLd certification characteristics specifically promise to meet ISO requirements.

Chemical reactor temperature and pressure monitoring: 4 analog inputs collect PT100 signals, and the heater output is jointly adjusted through the PID algorithm. MODBUS RTU connects to the DCS system, and the explosion-proof version of the equipment can be deployed in Zone 1.

Intelligent logistics sorting line: connected to the main control PLC through the PROFINET interface, integrated with 8-way relay output to control the sorting mechanism, receiving 24V DC sensor signals, achieving high-speed sorting, and fast response time (≤5ms)