0102030405

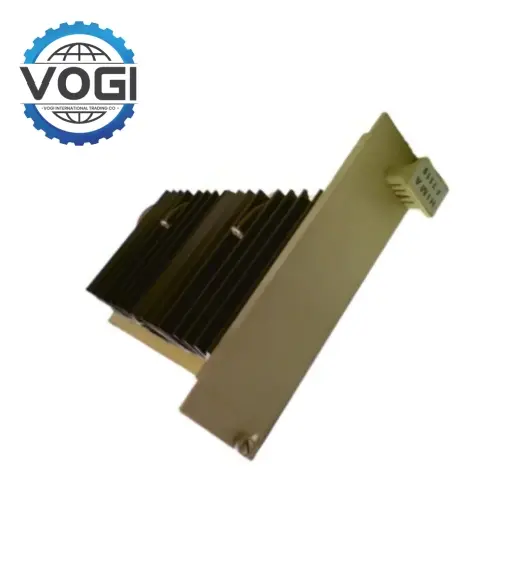

HIMA F7119 power supply module

Key SpecificationsVOGI

Module type: digital output module,

Output current: 5A

Number of output points: Commonly there are multiple output channels, which can control multiple external devices at the same time.

Signal isolation: above 2500V

Diagnostic function: With self-diagnosis capability,

Communication interface: The specific interface type and communication protocol are determined according to the product version and application requirements.

Safety level: Comply with relevant safety standards

Operating temperature range: - 40°C to + 85°C

Key FeaturesVOGI

Three-module redundant architecture: HIMA F7119 supports hardware redundant design. When any module fails or is about to fail, the system automatically switches to maintain zero interruption of control tasks. It is suitable for scenarios with high fault tolerance requirements such as nuclear power and aviation test benches.

Industrial communication protocol integration: HIMA F7119 supports PROFINET IRT, EtherNet/IP, Modbus TCP/RTU communication, with a communication rate of up to 100Mbps, supports data exchange with DCS, SCADA, and cloud platforms, and is suitable for cross-system collaborative control of smart factories.

High-density mixed signal processing: 16-bit resolution analog input, providing high-speed digital pulse counting, meeting the precision control requirements of servo positioning, vibration monitoring, etc.

Safe dynamic control algorithm engine: HIMA F7119 built-in PD/PS algorithm and anti-surge control model, real-time optimization of compressor and reactor operating parameters, suitable for natural gas processing plants, LNG receiving stations and other purposes.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$43 |

|

Southeast Asia |

$16 |

|

South Asia |

$56 |

|

South Africa |

$46 |

|

Europe and USA |

$27 |

|

Russia |

$51 |

APPLICATIONVOGI

Emergency shutdown system: Real-time monitoring of process parameters, triggering rapid shutdown response, and preventing the spread of accidents. It is suitable for high-risk environments such as natural gas processing plants and liquefied natural gas terminals.

Safety instrument system: Meets IEC 61511 SIL3 certification and is used for safety interlock control of high-risk processes. It is commonly used in refineries, chemical plants and other scenarios that require high-reliability safety protection.

Process safety monitoring: HIMA F7119 Continuous status monitoring of key equipment such as high-temperature and high-pressure reactors and distillation towers, providing real-time diagnosis and early warning, and is used in chemical production, nuclear power cooling systems and other scenarios.