0102030405

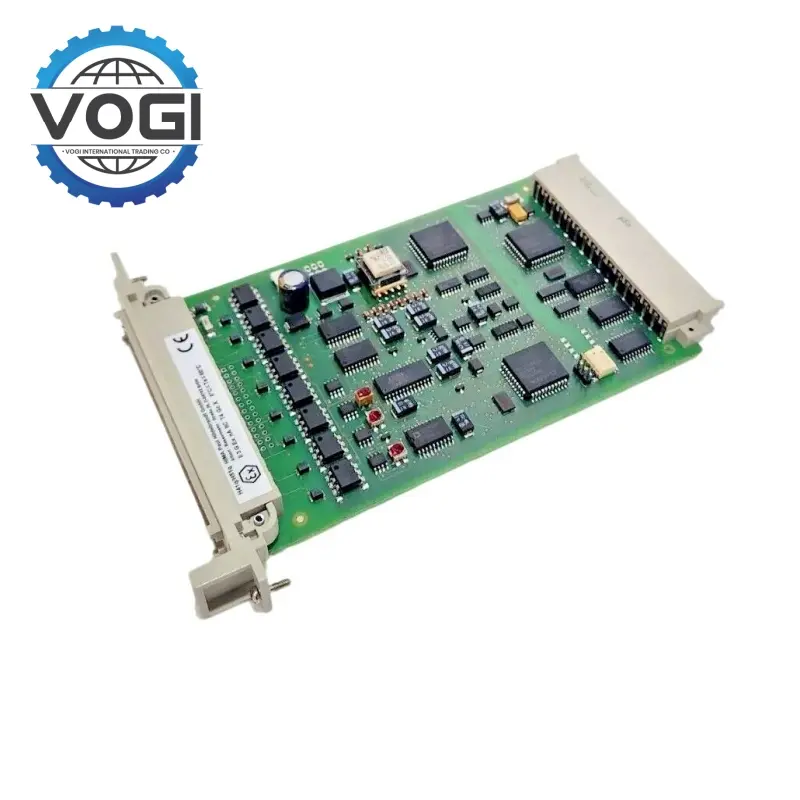

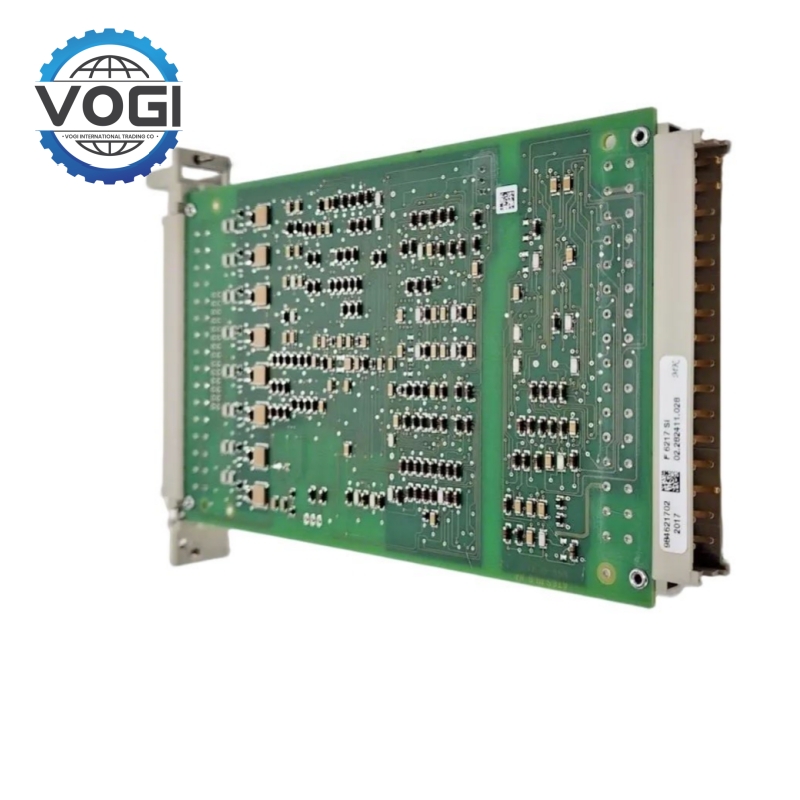

HIMA F8623B Communications Processors

Key SpecificationsVOGI

Working voltage: usually 24VDC,

Output voltage: 5VDC power supply,

Communication interface: with communication interface

Input and output characteristics: the specific number of input and output points and signal type may vary depending on the product model.

Diagnostic function: with self-diagnosis function

Operating temperature range: - 40°C to + 85°C

Protection level: such as IP65, with dust and water resistance

Key FeaturesVOGI

Customization: HIMA F8623B customized flexible complexity is an industrial control function that allows users to quickly monitor numerous sensor signals in real time through detailed preset logic. When dangerous equipment fails, process parameters exceed the limit, etc., emergency shutdown will be initiated, dangerous medium supply will be cut off, etc., to ensure the safety of personnel, equipment and environment.

Redundant reliability design: HIMA F8623B adopts a dual redundant architecture, which includes not only redundant processing, but also redundant power supply modules and communication links. When the main components fail, seamless switching ensures redundancy and allows continued operation. The overall reliability effectively reduces production downtime caused by the inability of equipment to be used normally.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$43 |

|

Southeast Asia |

$16 |

|

South Asia |

$56 |

|

South Africa |

$46 |

|

Europe and USA |

$27 |

|

Russia |

$51 |

APPLICATIONVOGI

Safety Instrumented System: Implements safety interlock control for high-risk industrial processes, such as emergency shutdown and valve closure, and is designed to comply with IEC 61511 SIL 3 certification, suitable for applications that require high reliability and safety protection, such as refineries and chemical plants.

Fire and Gas System: Combines flame and gas leak detection with fire and gas interlock control, has the ability to monitor multiple areas, and is applied to flammable and explosive environments, such as oil drilling platforms and storage tank areas.

Process Safety Monitoring: Continuously monitors the health of key equipment, such as high-temperature, high-pressure reactors and distillation towers, uses continuous monitoring for diagnosis and early warning, and is applied to chemical production systems, nuclear cooling systems, and other processes.