0102030405

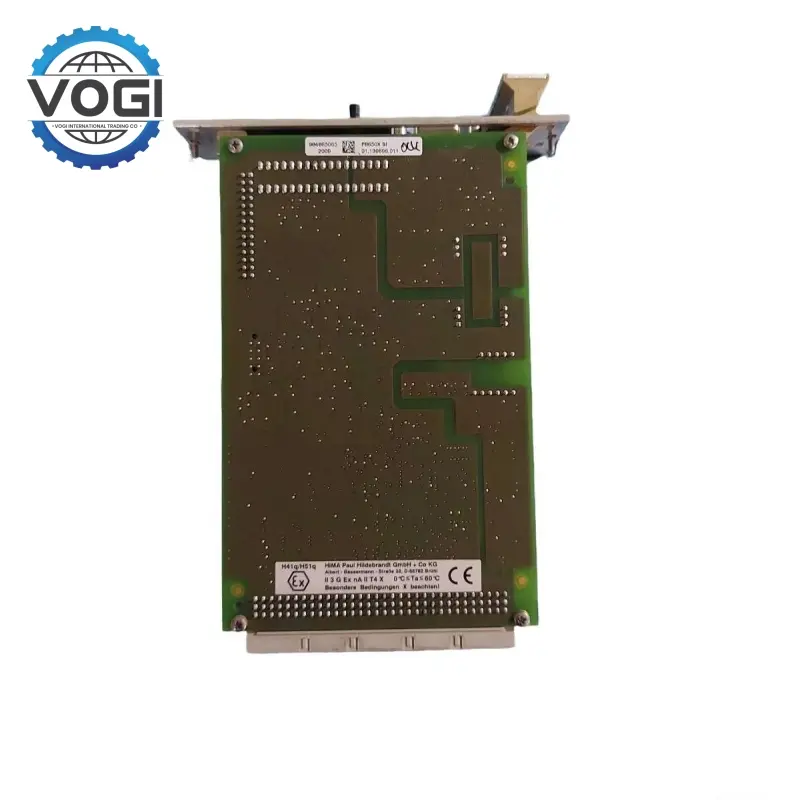

HIMA F8650X Central module

Key SpecificationsVOGI

Power input: 24V DC ±15%, supports redundant power supply to ensure system stability.

Processor architecture: dual-core processor, main frequency 25MHz, supports real-time data processing and safety control algorithms.

Memory configuration: 16MB RAM + 256MB flash memory, supports battery buffered data storage, power-off protection of key information.

Communication interface: dual Ethernet (10/100Mbps), RS-485/Modbus and USB interface, compatible with industrial protocols.

I/O capability: supports 16 mixed signal input/output, expandable analog (0-10V, 4-20mA) and digital modules.

Safety certification: SIL3/SIL4 certified, suitable for high-risk industrial scenarios.

Operating temperature: -40°C to + 85°C.

Protection level: IP67, excellent vibration and shock resistance.

Response time: ≤20ms, supports high-speed real-time control and emergency event processing.

Key FeaturesVOGI

High reliability and safety: Redundant architecture (1oo2D) and quadruple CPU design, strong single fault tolerance, meet SIL3/SIL4 safety level.Built-in overvoltage, overcurrent and thermal protection functions to ensure long-term stable operation of the system.

Flexible communication and integration: Multi-protocol support, seamless connection to DCS/PLC system and cloud platform. Dual Ethernet ports support linear, ring or star networking, enhancing network flexibility.

Intelligent diagnosis and maintenance: Real-time self-test, fault code prompt and module status monitoring, support remote maintenance.

Modularity and scalability: HIMA F8650X Support hot-swap, can quickly expand I/O, communication and other functional modules.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$50 |

|

Southeast Asia |

$40 |

|

South Asia |

$67 |

|

South Africa |

$54 |

|

Europe and USA |

$30 |

|

Russia |

$61 |

APPLICATIONVOGI

Energy and environmental protection: transformer monitoring in the power industry, real-time control of wastewater treatment, and process safety management in petrochemicals.

Rail transit: signal system redundancy control, tunnel ventilation and lighting intelligent management.

Intelligent manufacturing: factory IoT data collection, equipment energy efficiency optimization and predictive maintenance.

Industrial automation control: HIMA F8650X production line monitoring, robotic arm collaborative control and equipment status monitoring.

Safety-critical systems: emergency shutdown system (ESD), fire/gas detection, pressure/temperature over-limit protection.