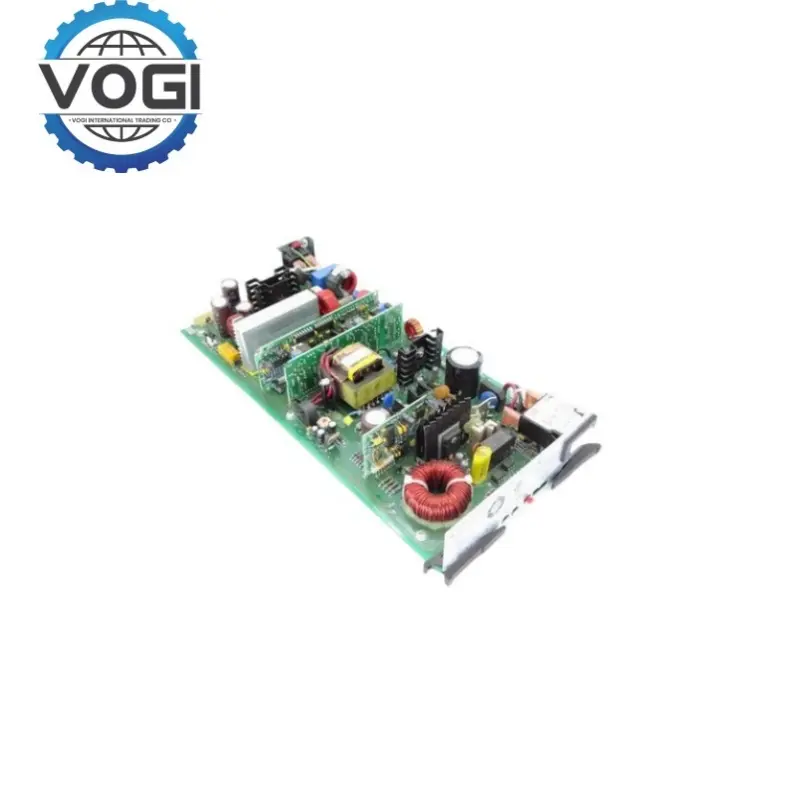

HONEYWELL 51196655-100 Power Supply Module

Key SpecificationsVogi

Input voltage range: 100-240V AC.

Output voltage: DC 24V and DC 12V±5% are available.

Power capacity: 100W and 1000W are available.

Efficiency: ≥90%.

Operating temperature: - 40°C to + 70°C and - 20°C to + 50°C are available.

Certification: CE, UL, FCC; CE, UL, RoHS.

Input signal type: 0-10V DC, 0-20mA, 4-20mA.

Output signal type: 0-10V DC, 0-20mA, 4-20mA.

Communication protocol: Modbus RTU, Ethernet/IP.

Functional FeaturesVogi

51196655-100 Other Connectors ADSS Power supply: The primary purpose of 51196655-100 as a power supply module is to convert the AC voltage into a certain stable DC voltage to provide input for other components or subsystems of industrial automation or safety systems. To enable normal operation of the various devices (controllers, sensors, actuators, etc.).

Overload, short circuit, over-temperature protection: It has overload, short circuit, over-temperature protection functions, when an abnormal situation (current exceeding, short circuit, overheating, etc.) occurs, it can self-protect to ensure that the power module and the entire system will not be damaged. In the case of abnormal operation, the module can take safety measures autonomously to stabilize and rescue the whole system.

Monitoring and diagnosis: In addition to basic power supply and protection functions, it also has monitoring and diagnosis functions, which can monitor the working status and parameters of the module in real time, including output voltage, current, temperature, etc. Through these parameters, potential faults can be discovered in time, preventive maintenance can be performed, and system downtime can be reduced.

Freight Estimation(Part Of The Area)Vogi

|

Destination |

Freight |

|

Middle East |

$43 |

|

Southeast Asia |

$31 |

|

South Asia |

$56 |

|

South Africa |

$46 |

|

Europe and USA |

$28 |

|

Russia |

$51 |

Application AreasVogi

Industrial automation: 51196655-100 is used in industrial automation processes such as manufacturing plants, chemical plants and refineries, including providing power and control signal support for PAC, DCS and other types of automation, so as to more accurately control and monitor the production process.

ManufacturingManufacturing: Used in the production of fabrication tools like robotic arms, conveyors, and machining centers. Supply of stable power supply, which maintenance normal operation and production efficiency, and quality.

Integrated Monitoring & Control Systems: Industrial facilities utilize monitoring and control systems such as environmental monitoring, building automation, and security systems that provide power to sensors, controllers, and communication devices that enable real-time collection, processing, and communication of data.