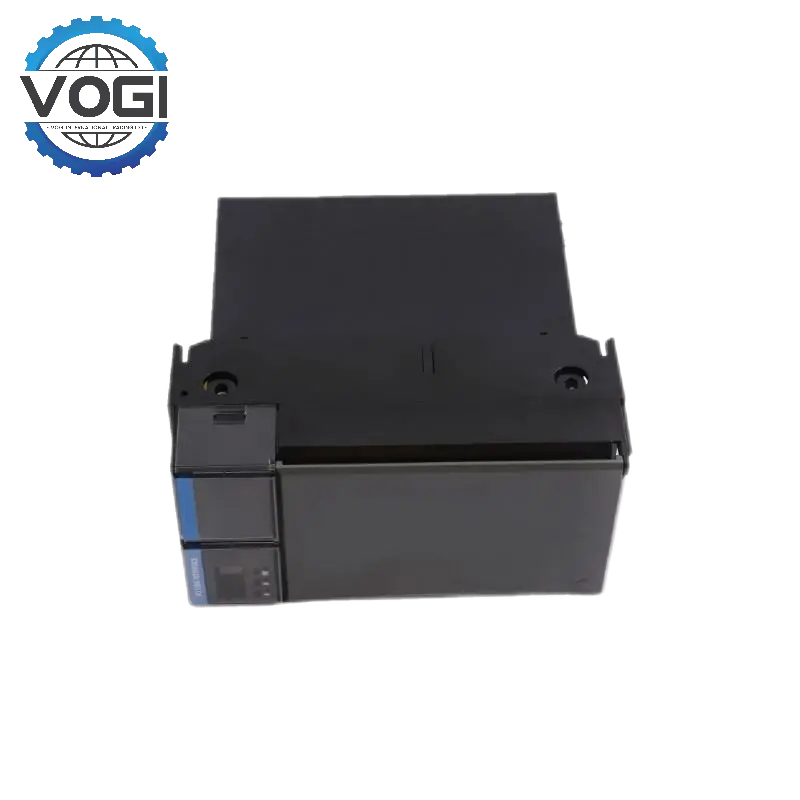

Honeywell TK-IOLI01 51403427-275 I/O Link Interface Module

Key SpecificationsVogi

Input/Output Channels: 16 configurable channels supporting analog (0-10V, 4-20mA) and digital (24V DC) signals.

Signal Isolation: 1500V AC channel-to-channel and channel-to-system isolation for noise immunity. Accuracy: ±0.1% full scale for analog signals, ensuring measurement integrity.

Communication Protocols: Native support for Modbus RTU/TCP, PROFIBUS DP, and HART® integration for legacy and modern systems.

Operating Temperature: -40°C to +70°C, suitable for extreme industrial conditions.

Power Supply: 18-32V DC with reverse polarity protection.

Response Time: <5 ms for digital signals; <50 ms for analog signal updates.

Freight Estimation(Part Of The Area)Vogi

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

Core FeaturesVogi

1.Universal Channel Configuration

Analog input/output, digital input/output and pulse counter each channel can be configured independently, eliminating the need for multiple special modules; This flexibility decreases inventory costs and helps create a simpler system design in mixed-signal space.

2.Advanced Diagnostics and Health Monitoring

They include embedded diagnostics that detect wiring faults, sensor failures, and out-of-range signals. Proactive maintenance, avoiding the downtime of key processes as real-time alerts using LED indicators or the system's software prevents operational aspects from changing.

3.Seamless Integration

Honeywell TK-IOLI01 supports standard protocols used in the industry for easy integration with PLCs, DCS, and SCADA systems. With HART® protocol support devices and analog signals can be transmitted simultaneously, which is perfect for smart sensor networks.

4.Ruggedized Construction

The TK-IOLI01 is encased in a corrosion-resistant aluminum body with front panel IP65 rating and is designed to withstand the rigors of dust, moisture and chemical exposure, making the TK-IOLI01 ideal for outdoor environments or hazardous area installations when combined with certification

5.Scalability

Honeywell's industrial bus architecture supports modular expansion with clusters of up to 32 modules on a single segment, allowing for cost-effective scaling of large installations.

ApplicationsVogi

Oil & Gas: Manage pressure transmitters on pipelines, control valve actuators, and can interface with HART®-capable field devices, allowing for remote diagnostics.

Chemical Processing: Collect temperature information from RTDs. Control the status of a pump through digital inputs. Initiate a safety shutdown when a rise or fall in pressure is detected.

Water Treatment: Those systems measure pH/conductivity through analog input, control dosing pumps with the help of digital output, and read off the meter pulse to record consumption.

Manufacturing: Connect to photoelectric sensors on assembly lines, read encoder signals for motor speed control, and interface with batching systems via Modbus.

Energy Management: Upscale data from solar/wind inverters (in analog form), track statuses of circuit breakers (in analog form), and load balancing in microgrids.