0102030405

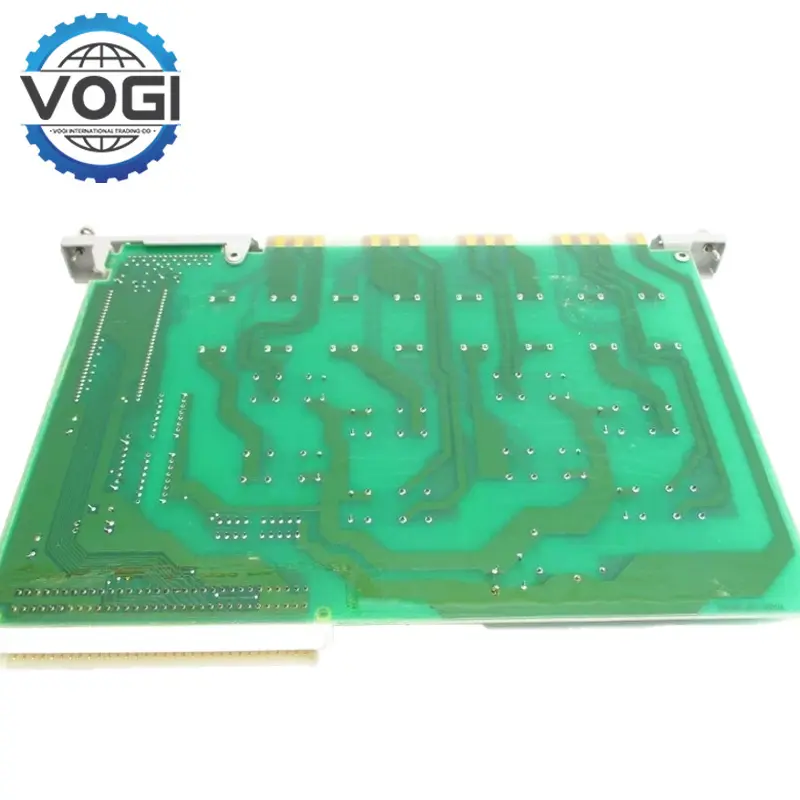

Siemens 505-4908 Relay Output Module

Key SpecificationsVOGI

Input Channels: 8 channels.

Compatible Thermocouple Types:

Type J, K, T, E, R, S, B, N, C, L.

Millivolt (mV) input capability.

Input Resolution: 16-bit analog-to-digital (A/D) conversion.

Accuracy: ±0.1% of full scale.

Temperature Range:

Operational: -25°C to +70°C.

Storage: -40°C to +85°C.

Isolation:

Channel-to-Channel: 250 V AC.

Field-to-System: 500 V AC.

Communication Interface:

PROFIBUS DP.

Optional HART protocol support.

Power Supply:

Voltage: 24 V DC.

Consumption: ≤ 2 W.

Diagnostics:

Per-Channel LED Status: Signal health, fault detection.

Open Thermocouple Detection: Yes.

Key FeaturesVOGI

Multi axis control and coordinate transformation: Capable of multi-axis simultaneous control, able to meet complex processing operations, such as cutting, milling, drilling, etc. Meanwhile, Siemens 505-4908 supports coordinate transformation functions so that the user can transform and adjust the coordinate system of the workpiece according to the actual situation, improving the flexibility and convenience of processing.

Fast Communication and Protocol Compatibility: Support Profinet IO protocol, communication speed up to 1 Gbps, support equal synchronous mode (IRT), cycle time can be as low as 1ms.

Programmable Control: Users have programmable control functions, for example defining machining programs via programming languages (G code, ISO code, etc.), achieving customized machining path and operations. Siemens 505-4908 provides the flexibility to customize processing as per varying production requirements, and to respond to various production tasks.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$34 |

|

Southeast Asia |

$15 |

|

South Asia |

$44 |

|

South Africa |

$36 |

|

Europe and USA |

$27 |

|

Russia |

$41 |

APPLICATIONVOGI

Aerospace: The machining accuracy and quality of aerospace components have strict requirements. These users can utilize the product's high positioning, speed, and torque control functions to process important components like aircraft engine blades and aircraft structural parts meeting stringent aerospace standards. Siemens 505-4908 also features a programmable control function, which allows for customized programming of the machining process based on the differences between the various components, thereby conforming to the production characteristics of small batches and many varieties in aerospace products.

Mold manufacturing: The processing of it is a typical case requiring high precision, which must guarantee both the dimensional accuracy and the surface roughness of the moulds, otherwise it would lead to poor quality of products. Siemens 505-4908 operates with multi axis control and coordinate transformation functions, enabling machining of complex mold shapes, and with programming to realize different processing processes, such as electrical discharge machining, wire cutting: to meet the needs of many customers for mold manufacturing.

Mechanical processing: In the general mechanical processing industry, no matter it is single piece small batch production or large-scale batch production, Siemens 505-4908 can play an important role Reactors. User can have control other machine tools and equipment, like the milling machine, lathe, drilling machine, etc. Is simple to use interface and remote monitoring function enhance processing efficiency rapid solve the production process problem.