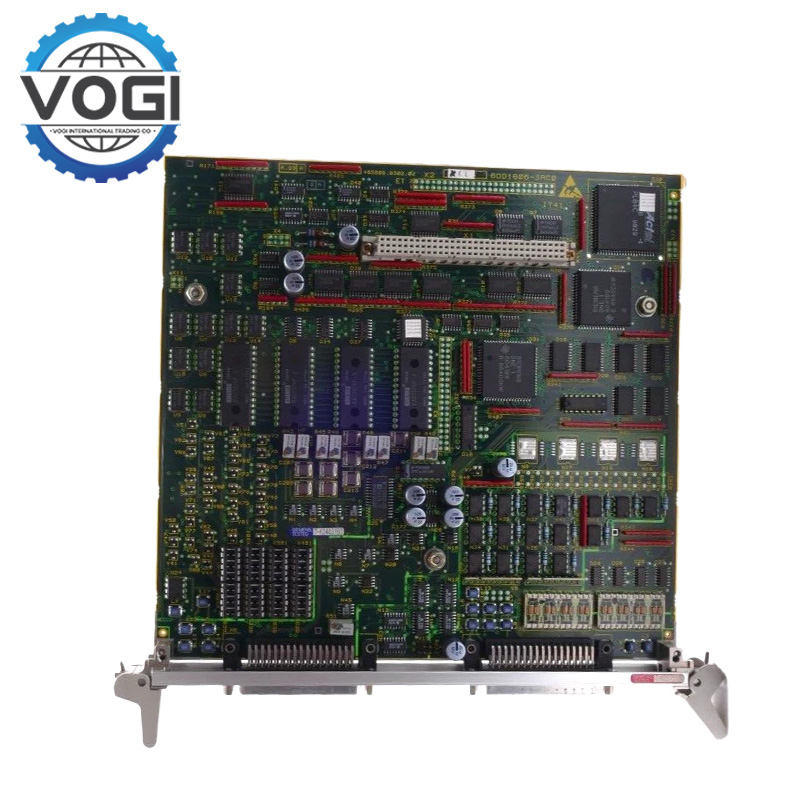

Siemens 6DD1606-3AC0 I/O Module

Key SpecificationsVOGI

Input Channels: 16 digital inputs.

Input Voltage: 24 V DC (nominal).

Input Type: Sink/source (PNP/NPN compatible).

Isolation: Galvanic isolation between channels and backplane.

Response Time: ≤ 1 ms.

Power Supply: 24 V DC (via system backplane).

Operating Temperature:

Standard: -20°C to +60°C.

SIPLUS variant: -40°C to +70°C (with condensation protection).

Key FeaturesVOGI

High-performance IO functions: Siemens 6DD1606-3AC0 supports multiple kinds of input/output functions (16 digital input (BI), 16 digital output (BO), 4 analog input (AI), 4 analog output (AO), 4 incremental encoder input). This allows it to seamlessly link a variety of field devices, such as sensors, actuators, motors, etc., to perform accurate measurement and control of various physical quantities in industrial processes.

Data desensitization and compression: It supports local data encryption and compressed transmission, reduces bandwidth usage and improves security.

Flexible scalability and configuration capabilities: Siemens 6DD1606-3AC0 functions can be expanded by inserting additional modules and bus connectors, supports BiCo internal functional interconnection technology, and realizes free configuration of I/O ports, which is convenient for users to flexibly combine and expand system functions according to actual application needs, and improve the adaptability and flexibility of the system.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

APPLICATIONVOGI

Unmanned mines: Siemens 6DD1606-3AC0 can connect unmanned mining trucks with dispatching systems, transmit positioning and load data through TSN, optimize transportation routes, and improve efficiency by more than 20%.

Subsea oil and gas monitoring: On the subsea oil production platform, the module transmits pressure and temperature data through optical fiber Ethernet, supports network disconnection and AI anomaly detection, and ensures safe production.

Smart warehousing: In the WMS system, Siemens 6DD1606-3AC0 supports RFID data and PLC linkage, and combines edge computing to achieve automatic inventory counting and dynamic path planning.

Automobile manufacturing: In stamping, welding, and painting workshops, CP 443-1 Advanced synchronizes robot cluster actions through TSN to achieve sub-millisecond response. For example, a car company uses its AI engine to optimize welding parameters in real time, and the yield rate increases by 15%.