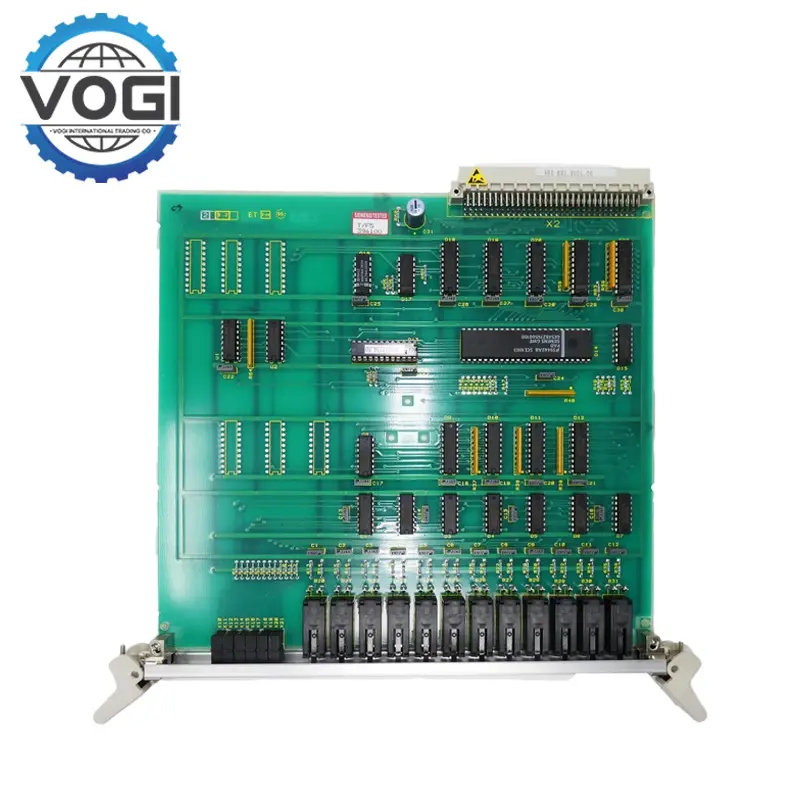

Siemens 6DD2920-0AD0 Light Receiver Module

Key SpecificationsVOGI

Input Channels: 16 (24 V DC, sink/source compatible).

Input Current: 7 mA per channel.

Isolation: Channel-to-channel and field-to-system (500 V AC).

Supply Voltage: 24 V DC (20.4–28.8 V).

Connection: Front connector with screw-type terminals.

Operating Temperature: -25°C to +60°C.

Key FeaturesVOGI

Mixed signal interface: Siemens 6DD2920-0AD0 supports 24 analog inputs (16-bit resolution), 16 digital inputs/outputs and 4 high-speed counters (1MHz), which can directly connect to complex devices such as pressure sensors, encoders, and laser rangefinders.

Deterministic network support: Based on the Profinet IRT (isochronous real-time) protocol, it realizes deterministic data transmission with a communication cycle as low as 250μs, ensuring accurate synchronization of scenarios such as multi-axis motion control and high-speed visual inspection.

Radiation-resistant hardened design: With special packaging and redundant circuit design, Siemens 6DD2920-0AD0 can still operate stably in strong electromagnetic interference (EMC Class A) or radiation environments (such as satellite ground stations).

Containerized deployment: Siemens 6DD2920-0AD0 has a built-in lightweight container engine, which can run Dockerized control algorithms (such as model predictive control MPC) to achieve rapid iteration and remote update of control logic.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

APPLICATIONVOGI

Waste treatment industry: In waste treatment plants, Siemens 6DD2920-0AD0 can be used to control the operation of waste incinerators. It can collect various parameters in the waste incineration process, such as temperature, pressure, oxygen content, etc., and through the analysis and processing of these parameters, it can achieve precise control of the waste incineration process, improve combustion efficiency, and reduce pollutant emissions.

New energy and energy storage system: It is used for multi-channel voltage/internal resistance detection of lithium battery component equipment, supports 0.05mV high-precision acquisition, and improves battery sorting consistency.

Semiconductor and precision manufacturing: Control the nano-level positioning of the wafer stage in the lithography machine (with linear motor and laser interferometer), and eliminate thermal expansion errors through multi-channel synchronous sampling. In 3D printing equipment, Siemens 6DD2920-0AD0 can adjust the laser power and powder feeding rate in real time to ensure the molding quality of complex metal components.