0102030405

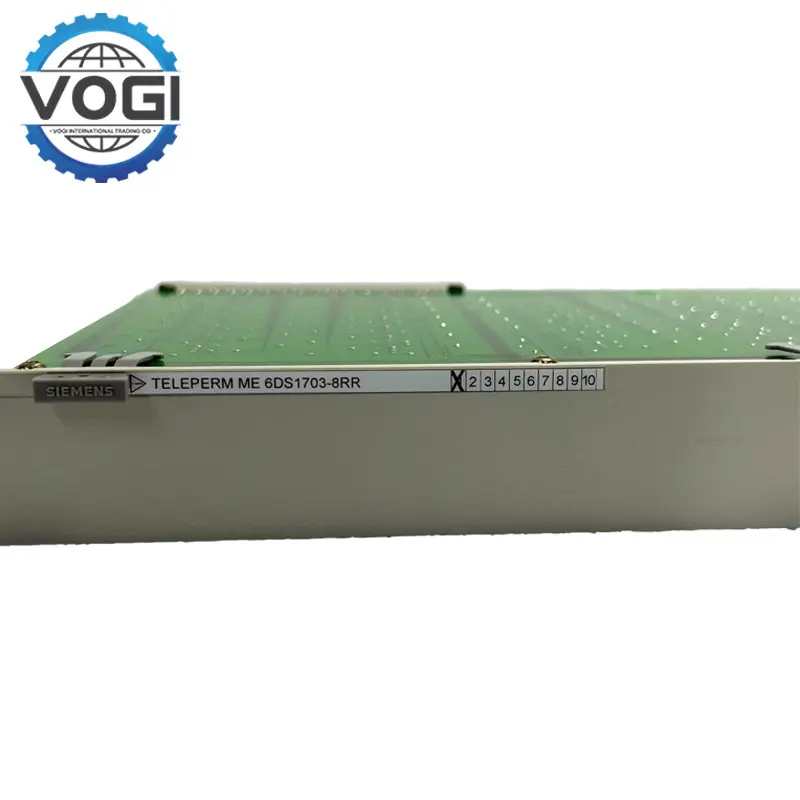

Siemens 6DS1703-8RR Measurement-Point Extension Module

Key SpecificationsVOGI

Operating Voltage: 24 V DC.

Current Consumption: ≤ 200 mA.

Input Range: 0 - 10 V / 4 - 20 mA.

Output Type: Digital, analog.

Communication Protocol: Profinet, EtherCAT.

Temperature Range: - 25 °C to + 60 °C.

Compatibility: Compatible with Teleperm M and Teleperm ME process control systems.

Key FeaturesVOGI

High-precision signal processing capability: Siemens 6DS1703-8RR is equipped with 16 safety inputs and 8 safety outputs, supporting a variety of signal types.

Analog processing: Built-in 2-channel 16-bit ADC converters, sampling rate 1kHz, support PID closed-loop control algorithm, suitable for safe monitoring of process variables such as temperature and pressure.

OPC UA and MQTT extension: Built-in OPC UA server, which can seamlessly connect to SCADA systems (such as WinCC Advanced), and supports MQTT protocol to achieve cloud data synchronization to meet the needs of industrial Internet of Things.

Cost-effective: Modular design reduces the wiring complexity, and shortens the project implementation cycle by 20%, is particularly suitable for small and medium-sized factory transformation.

PROFINET/PROFIBUS dual network integration: Siemens 6DS1703-8RR supports RT (real-time) and IRT communication modes, with a baud rate of up to 12Mbps, ensuring low-latency transmission of safety data (such as ESD signals).

Life and maintain hot swapping: MTBF (mean time between failures) is greater than 500,000 hours, and key components (relays, optocouplers) support hot swapping and repair to minimize downtime losses.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$34 |

|

Southeast Asia |

$15 |

|

South Asia |

$44 |

|

South Africa |

$36 |

|

Europe and USA |

$24 |

|

Russia |

$41 |

APPLICATIONVOGI

Automotive manufacturing: On the factory's robot welding production line, it is used to achieve safety control of the human-machine collaboration area (HCR). By integrating the 3D vision system and the safety fence sensor, the module monitors the operator's position in real time. When a person enters the danger zone, the robot is triggered to stop and the sound and light alarm is activated within 0.5ms. At the same time, its high-precision input channel is used to monitor the joint torque of the welding robot to prevent mechanical failure caused by overload.

Chemical process: Siemens 6DS1703-8RR is responsible for controlling the pressure-temperature interlock system of the reactor. When the pressure exceeds 1.2MPa or the temperature deviates from the set value by ±5%, the F-CPU immediately cuts off the feed valve and starts the emergency cooling circuit. Thanks to the redundant design of the module, even if the main power fails, the backup battery can still maintain safe output for 30 seconds to ensure process safety.

Rail transit: Siemens 6DS1703-8RR is used to implement train door safety interlock (MSL). By collecting the status of the platform screen door, the track occupancy detection signal (axle counter) and the on-board ATO instruction, the module completes the logical judgment within 10ms. If it detects that the door is not closed or the track is occupied, it immediately sends an EB (emergency brake) command to the interlocking system, which meets the SIL 4 requirements of the EN 50128 railway signal system.