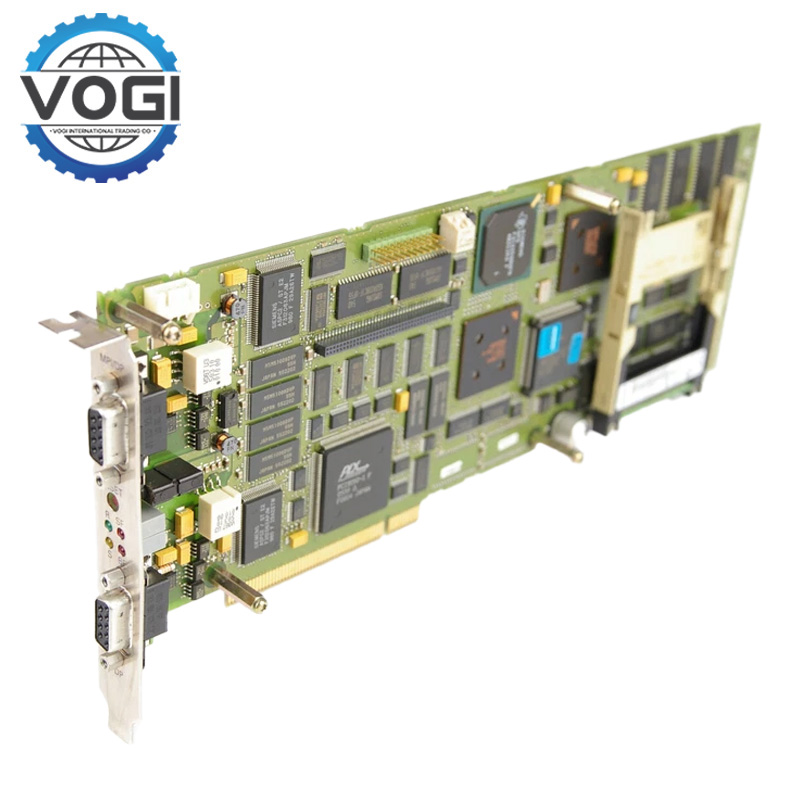

Siemens 6ES7616-2QL00-0AB4 Memory Card

Key SpecificationsVOGI

Work Memory: 1 MB (for code/data).

Load Memory: 5 MB (expandable via SIMATIC memory card).

Bit Execution Time: 1 ns (minimum).

Integrated Interfaces:

PROFINET: 2x RJ45 (1x PROFINET IRT, 1x PROFINET RT).

PROFIBUS: 1x RS-485 (DP master/slave).

Max. I/O Expansion: Up to 8192 modules (distributed via PROFINET/PROFIBUS).

Digital I/O: 32,768 channels (max).

Analog I/O: 4096 channels (max).

Motion Control: Supports up to 30 axes.

Power Supply: 24 V DC.

Power Consumption: 8 W.

Protection Class: IP20.

Operating Temperature: 0–60°C.

Key FeaturesVOGI

Super computing power: Siemens 6ES7616-2QL00-0AB4 is equipped with a dual-core processor with a main frequency of 1.8 GHz, it supports multi-threaded parallel processing and can easily cope with high-speed motion control (such as servo positioning) and complex algorithms (such as predictive maintenance).

Large storage capacity: 4MB RAM and 8MB Flash are integrated to support offline program storage and real-time data caching. Users can expand to 32MB storage module to meet the data management needs of large equipment throughout the life cycle, such as the recipe database storage of food packaging lines.

Dual-core heterogeneous design: The dedicated motion control core is separated from the general logic processing core, which does not affect the response speed of the main program when performing CNC interpolation operations, which has significant advantages in scenarios such as injection molding machine clamping control.

Energy management module: Built-in power metering chip, Siemens 6ES7616-2QL00-0AB4 supports IEC 61557 standard, can monitor the power consumption of each branch in real time, and provide data support for energy efficiency optimization of smart factories.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

APPLICATIONVOGI

Automobile manufacturing: In the stamping workshop, Siemens 6ES7616-2QL00-0AB4 can synchronously control the 6-axis robot and conveyor system, and cooperate with the visual system to achieve a body component grasping accuracy of 1,200 pieces per hour (repeat positioning ±0.02mm). In the painting process, the robot spraying path is coordinated through PROFINET, saving 15% of paint.

High-speed packaging line: For the three-in-one production line of metal detection, weighing and packaging in the food industry, multi-task time-sharing scheduling technology is adopted to simultaneously handle foreign body detection (10ms response), weight compensation (dynamic adjustment) and inkjet printer synchronization to ensure a production rhythm of 400 packages/minute.

Smart warehousing: Siemens 6ES7616-2QL00-0AB4 integrates AGV navigation and stacker control, and realize millisecond-level interaction between the stereoscopic warehouse and the WMS system through the built-in CIP Motion protocol. After deployment in an e-commerce logistics center, the sorting efficiency reached 3,000 pieces/hour, and the path conflict rate decreased by 80%.