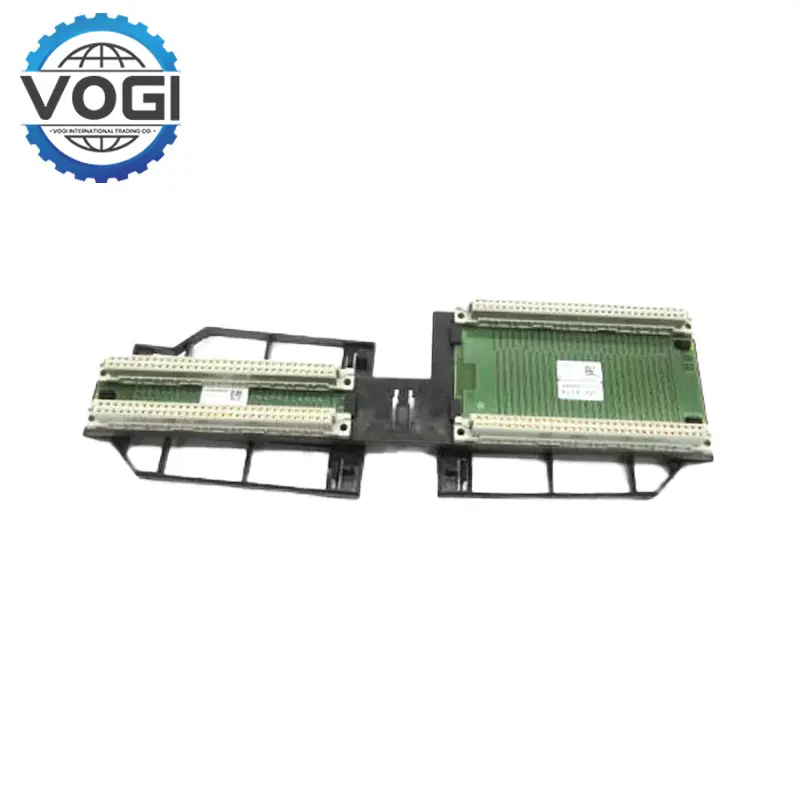

Siemens 6SE7090-0XX84-4HA0 Local Bus Adapter

Key SpecificationsVOGI

Rated Power: 37 kW.

Input Voltage:

3-phase: 380–480 V AC (±10%).

Frequency: 47–63 Hz.

Output Current: 72 A (continuous).

Output Frequency: 0–300 Hz.

Control Method: Vector control.

Communication Interfaces:

PROFIBUS DP (optional).

RS-485 (USS protocol).

Ambient Temperature:

Operation: 0°C to 40°C (derating above 40°C).

Storage: -25°C to 70°C.

Enclosure Rating: IP23 (open chassis design, requires cabinet mounting).

Key FeaturesVOGI

Quick connection interface: Siemens 6SE7090-0XX84-4HA0 is equipped with crimp terminals and shielded cable slots, supports parallel multi-module expansion power (maximum 4 modules cascaded), reducing the complexity of on-site wiring.

Modular packaging: A combination of aluminum alloy heat dissipation substrate and corrugated resistor belt, surface oxidation treatment improves corrosion resistance, protection level IP23, supports vertical or horizontal installation.

Dynamic braking response: Siemens 6SE7090-0XX84-4HA0 supports inverter DC bus voltage threshold (default 670V DC) to trigger braking, response time <2ms, to prevent bus over-voltage from causing equipment shutdown.

Dynamic temperature control: built-in temperature sensor (PTC thermistor), real-time feedback of resistor body temperature to the inverter, triggering overheating load reduction or alarm.

Fault chain protection: Siemens 6SE7090-0XX84-4HA0 forms a triple protection chain with the inverter and motor, and immediately cuts off the IGBT drive signal when the resistor is overheated or short-circuited to avoid device damage.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$34 |

|

Southeast Asia |

$15 |

|

South Asia |

$44 |

|

South Africa |

$36 |

|

Europe and USA |

$24 |

|

Russia |

$41 |

APPLICATIONVOGI

Injection molding machine clamping mechanism: Siemens 6SE7090-0XX84-4HA0 suppresses inertial vibration during the mold closing stage to ensure the consistency of molded parts size.

Port crane: realize precise parking control during container lifting, reduce the swing of the hoist, and improve loading and unloading efficiency.

Metro braking system: auxiliary traction inverter absorbs braking energy, and cooperates with regenerative energy storage device to achieve 80% energy reuse.

Mine hoist: Siemens 6SE7090-0XX84-4HA0 quickly consumes potential energy during emergency stop or emergency power failure to prevent the hoist from sliding, and combine with mechanical brake to achieve double safety protection.

Steel rolling mill: compensate for the reverse electromotive force generated by the rapid deceleration of the roller, maintain the stability of the DC bus voltage, and avoid fluctuations in rolling accuracy.