0102030405

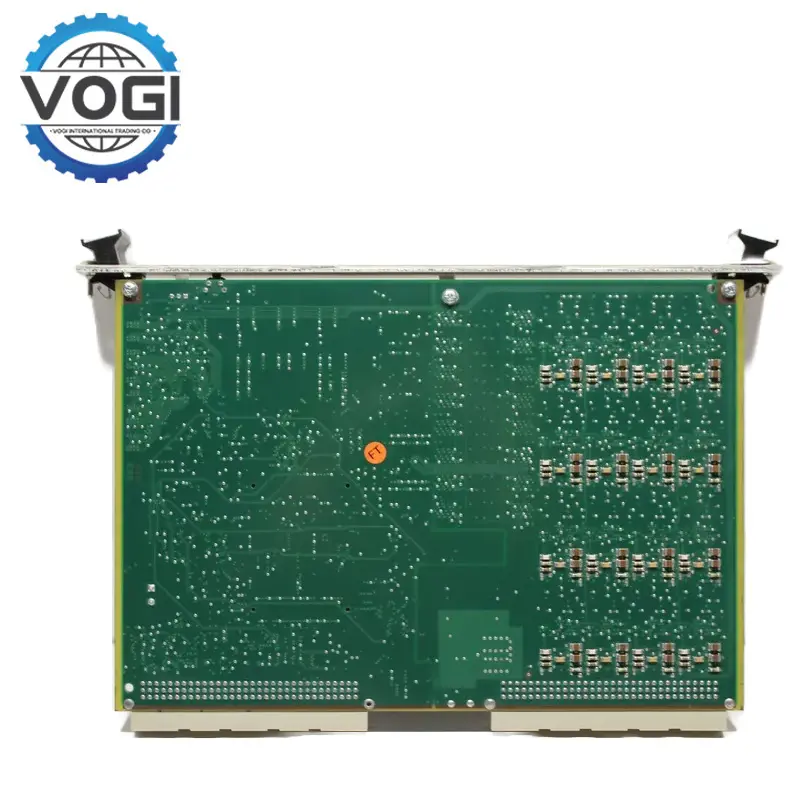

Vibration CMC16 200-530-025-014 Condition Monitoring Card

Key SpecificationsVOGI

Operating Voltage: 12-30 V DC.

Current Consumption: ≤25 mA.

Temperature Range:

Operational: -40°C to +85°C.

Storage: -50°C to +100°C.

Frequency Range: 0.5 Hz to 10 kHz (±3dB).

Measurement Range:

Acceleration: ±50 g peak.

Velocity: 0-20 mm/s RMS.

Output Signal:

Analog: 4-20 mA / 0-5 V DC.

Digital: RS-485 (Modbus RTU).

Protection Rating: IP67.

Sensitivity: 100 mV/g ±5%.

Resonant Frequency: >25 kHz.

Key FeaturesVOGI

Powerful data acquisition capabilities: Vibro CMC16 has 16 independently configurable dynamic channels that can simultaneously collect multiple types of signals, including speed, phase reference, vibration (acceleration, velocity or displacement), dynamic pressure, etc., to meet different monitoring needs.

Intelligent data analysis and alarm functions: The onboard processor can handle all data acquisition control, conversion from time domain to frequency domain (fast Fourier transform), frequency band extraction, unit conversion, limit checking and other operations, and can generate alarm signals based on preset thresholds and conditions. Each frequency band has 6 configurable alarms with hysteresis dead bands to detect abnormal conditions in equipment operation in a timely manner.

Advanced communication capabilities: Vibro CMC16 supports Ethernet and serial RS-485 communication options, which can easily transmit and communicate data with the host computer or other devices for remote monitoring and system integration.

Data storage and recording functions: It has onboard buffer storage to temporarily store data for query and analysis when needed. It also supports log recording based on schedule, "alarm" and "abnormal", which is convenient for users to trace and analyze the equipment operation history.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$34 |

|

Southeast Asia |

$15 |

|

South Asia |

$44 |

|

South Africa |

$36 |

|

Europe and USA |

$24 |

|

Russia |

$41 |

APPLICATIONVOGI

Power generation sector: Status monitoring of generators, motors, transformers and other equipment using Vibro CMC16. Real-time monitoring of the operating status of equipment by collecting signals such as vibration, speed, displacement, etc., and timely find hidden faults of the equipment (such as bearing wear, rotor imbalance, winding short circuit, etc.) to ensure the safe and stable operation of power equipment, reduce downtime and maintenance costs.

Chemical Industry: It can monitor rotating equipment in chemical production, such as compressors, pumps, fans, etc. These equipment generally have abnormal vibration during working process, leading to equipment damage or even safety accidents. Vibro CMC16 can realize real-time monitoring and trend analysis of equipment vibration, provide more reasonable basis for maintenance and management of equipment, and ensure the continuity and safety of chemical production.

Machinery manufacturing industry: Suitable for status monitoring of a variety of machine tools, machining centers, industrial robots and other equipment. The accuracy of processing, improve production efficiency through monitoring of the equipment vibration signal, analysis of the equipment operating status, predict the trend of equipment failure, to guide the equipment part of the repair and maintenance.

Metallurgical industry: In metallurgical industry production, the working condition of large equipment such as blast furnaces, converters, and continuous casting machines is an important guarantee for production. Vibro CMC16 can also be used to monitor the vibration of the key components of these equipment, such as motors, reducers, rollers, etc. within the equipment, so as to detect equipment failures in time, and avoid production downtime and quality problems caused by equipment failures.