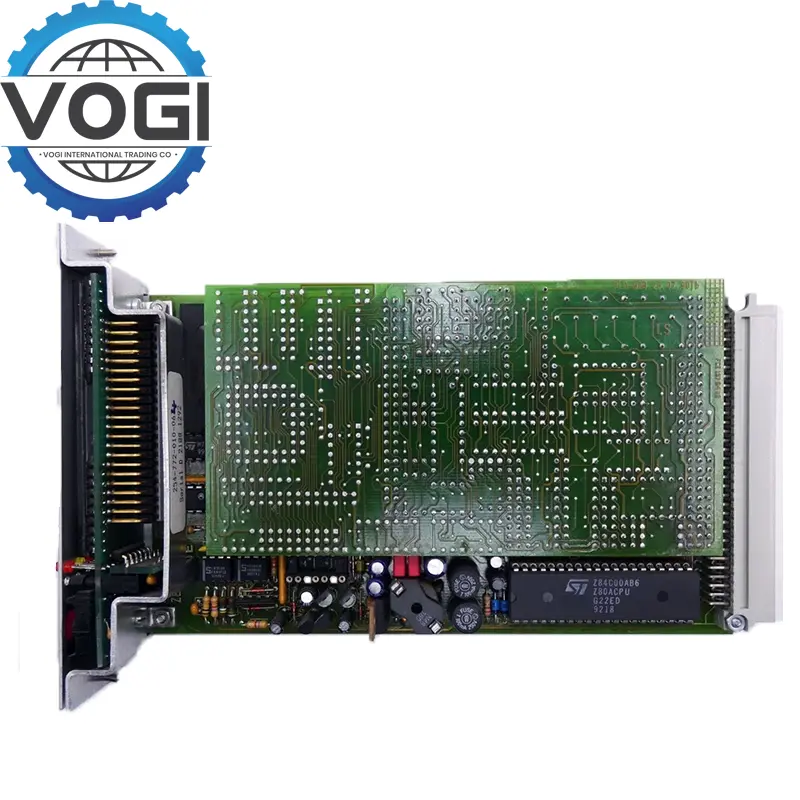

Vibro-Meter 254-772-000-224 Level Detector&Digital Display Module

Technical ParametersVOGI

Form Factor & Power

VM600 6 U card, hot-swappable under power

24 V DC from rack backplane, < 100 mA

Inputs & Display

Accepts a single 0–10 V DC signal (high impedance > 100 kΩ)

Front-panel LED bargraph (≈ 20–32 segments) showing level

Green “OK” LED indicates valid signal; yellow/red LEDs indicate “Alert”/“Danger” thresholds

Environmental & Physical

Operating: –25 °C to +65 °C; humidity up to 95 % non-condensing

Shock: 6 g/11 ms (IEC 68-2-27); Vibration: 5–35 Hz at 0.15 mm > 35 Hz at 1 g (IEC 68-2-6)

Key Features

VOGI

Instant Bargraph Feedback

Rapid visual indication of shaft-to-probe distance or vibration amplitude—operators see at a glance whether values are in a normal range or approaching limits.

Integrated Fault Detection

“OK” LED monitors sensor/conditioner chain; if the input is open, shorted, or out of range, the LED blinks/off to flag a wiring or sensor issue.

Dual Alarm Thresholds

Two programmable levels (Alert & Danger) trigger yellow/red LEDs; alarm contacts route through the VM600 I/O card for interlocks or DCS integration.

Hot-Swap & Rugged Design

Removable under power to minimize downtime; optional conformal coating and EMI/RFI-resistant enclosure for harsh environments.

Seamless VM600 Integration

Works with UVV 697, IQS 450/452, CMC, etc.; multiple modules can be “ganged” to create a local status-wall bargraph bank.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

Applications

VOGI

Turbine Shaft Alignment Check

UVV 697 conditions dual proximity probes on a steam turbine. Two PLD772 modules display vertical/horizontal shaft position during startup. Operators instantly verify the shaft remains centered without SCADA screens.

Compressor Bearing Vibration Display

IQS 450 outputs 0–10 V proportional to bearing-shell velocity on an oil refinery compressor. Four PLD772 cards show each bearing’s vibration level; yellow/red LEDs map to 4 mm/s and 8 mm/s thresholds. DCS-interfaced alarms trigger automatic load reduction if needed.