0102030405

Vibro-Meter CE620 444-620-000-011 A1-B100 rack power supplies

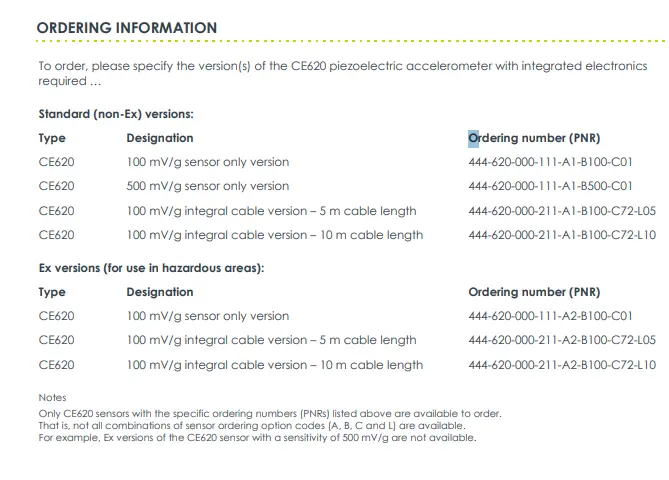

ordering informationVOGI

KEY FEATURES AND BENEFITS

• From the vibro-meter® product line

• Voltage output signal: 100 or 500 mV/g

• Frequency response: 0.5 to 14000 Hz (100 mV/g versions) 0.2 to 3700 Hz (500 mV/g versions)

• Temperature range: −55 to 120°C (100 mV/g versions) −55 to 90°C (500 mV/g versions)

• Isolated electronics with internal shield for reduced noise and improved bias-voltage stability

• Ground isolated from case

• Available as a sensor only or with an integral cable

• Available in standard versions and Ex versions certified for use in hazardous areas

Related supporting products

VOGI

Sensor matching

Vibration sensor: such as Vibro-Meter 200 series, compatible with CE620 input.

Temperature sensor: PT100 or thermocouple for auxiliary temperature monitoring.

System integration

Preamplifier: CE620 can be used as a submodule of VM600 series monitoring system.

Communication interface: Vibro-Meter CE620 444-620-000-011 A1-B100 is connected to DCS/PLC system through Modbus, Profibus and other protocols.

Software and analysis tools

VibroSuit software: for configuration, data logging and diagnostic analysis.

Third-party platform: such as OSIsoft PI System or GE Bently Nevada System 1.

Auxiliary equipment

Signal distributor, explosion-proof housing.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$35 |

|

Southeast Asia |

$15 |

|

South Asia |

$45 |

|

South Africa |

$37 |

|

Europe and USA |

$24 |

|

Russia |

$42 |

Applications

VOGI

Industrial rotating equipment monitoring

Power generation industry: gas turbines, steam turbines, wind turbines, water turbines, etc.

Oil and gas: compressors, pumps, gas engines, pipeline transportation equipment.

Manufacturing industry: motors, gearboxes, fans, centrifuges, papermaking machinery.

Rail transportation: train traction motors, bearing monitoring.

Critical equipment protection

Vibro-Meter CE620 444-620-000-011 A1-B100 monitors parameters such as vibration and temperature in real time, triggering alarms or shutdowns to prevent mechanical failures.

Predictive maintenance (PdM)

Vibro-Meter CE620 444-620-000-011 A1-B100 works with analysis software to detect signs of equipment degradation in advance through trend analysis.